A reagent disk magnetic bead mixing device and its application method

A reagent disk and mixing technology, which is applied in the field of fully automatic magnetic particle chemiluminescence immunoassay analyzer equipment, can solve the problems of wear of moving parts of the reagent disk, reduced service life, and low success rate of scanning codes, etc., so as to shorten the experiment time and reduce the Wear and reduce the effect of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

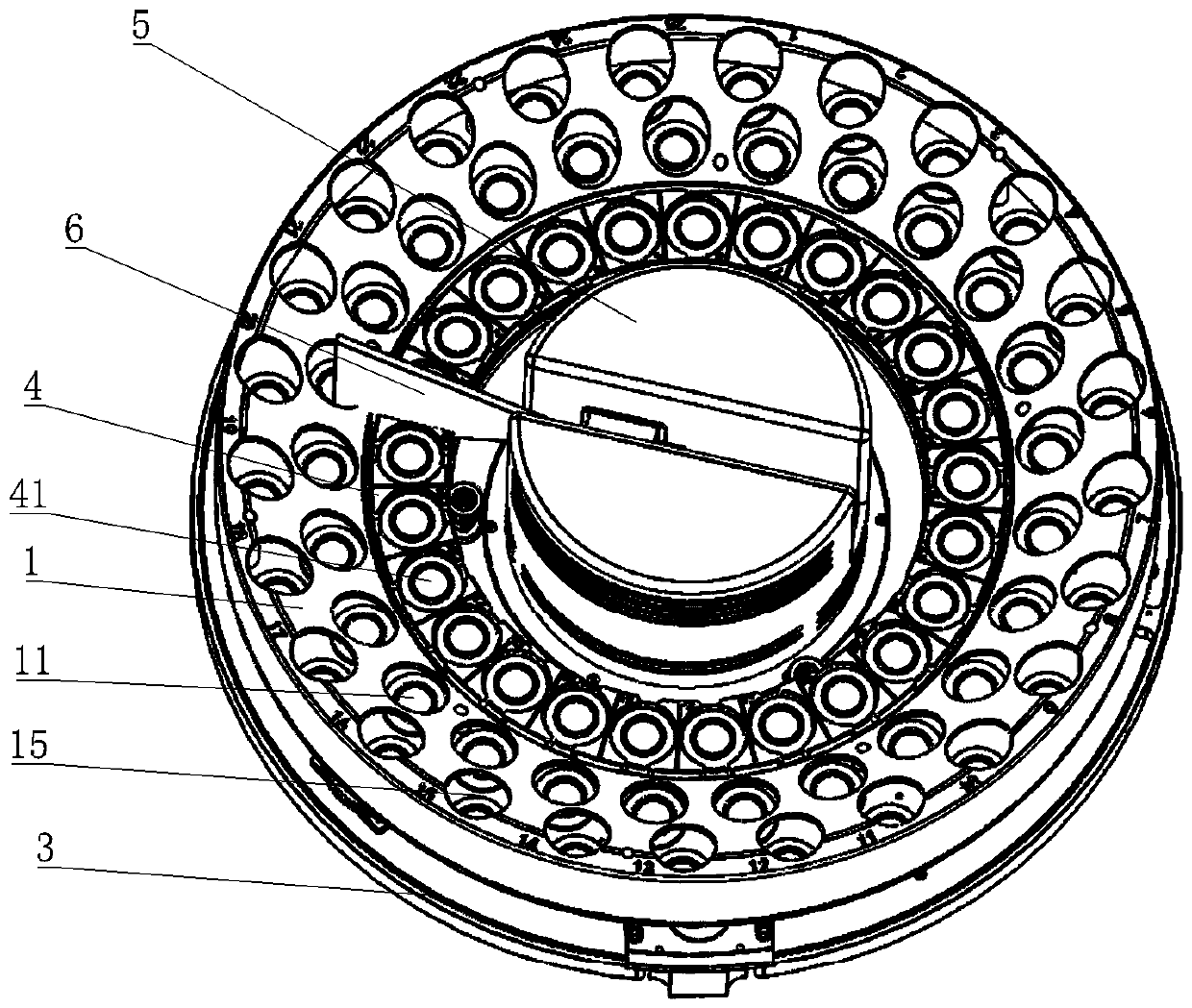

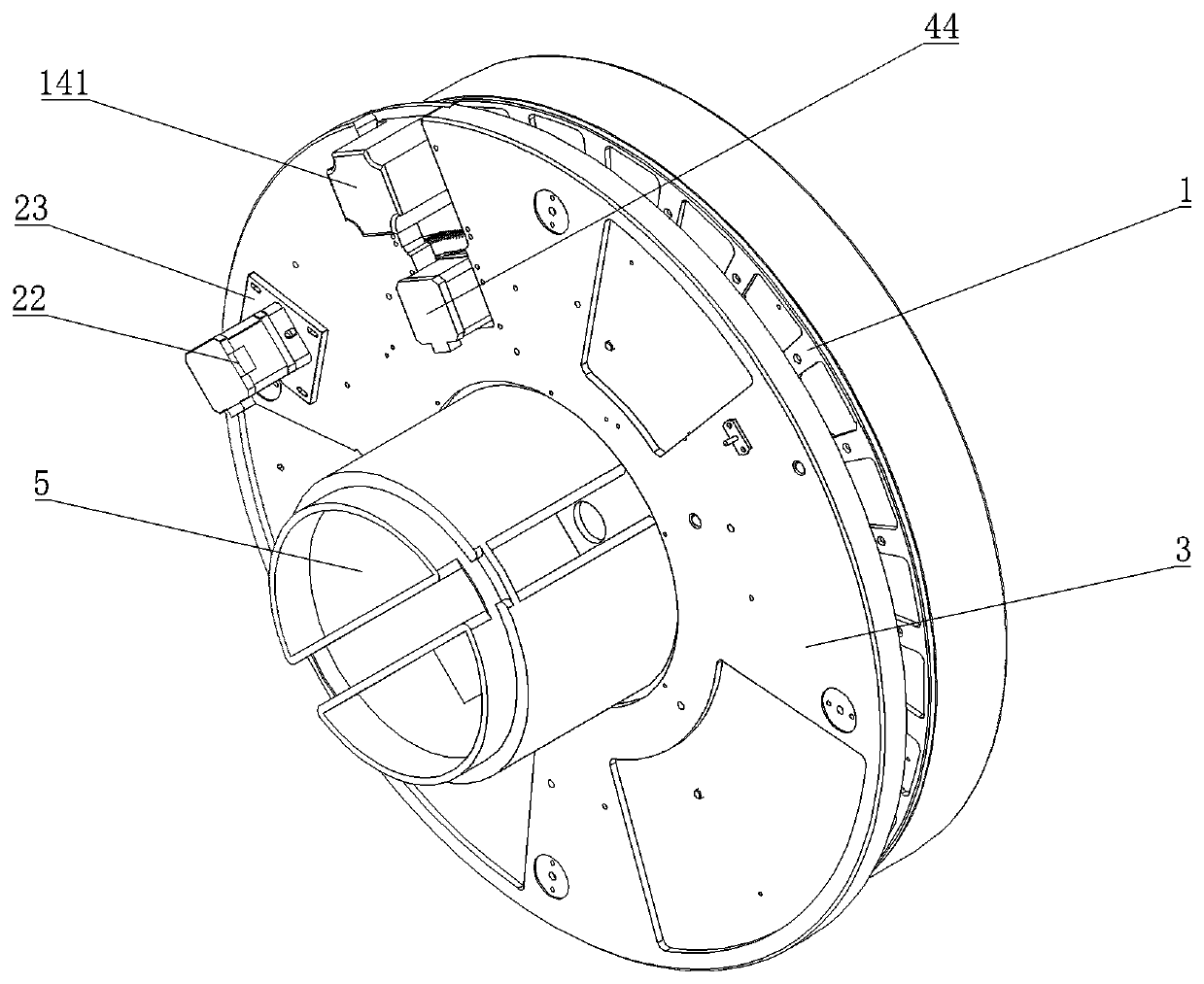

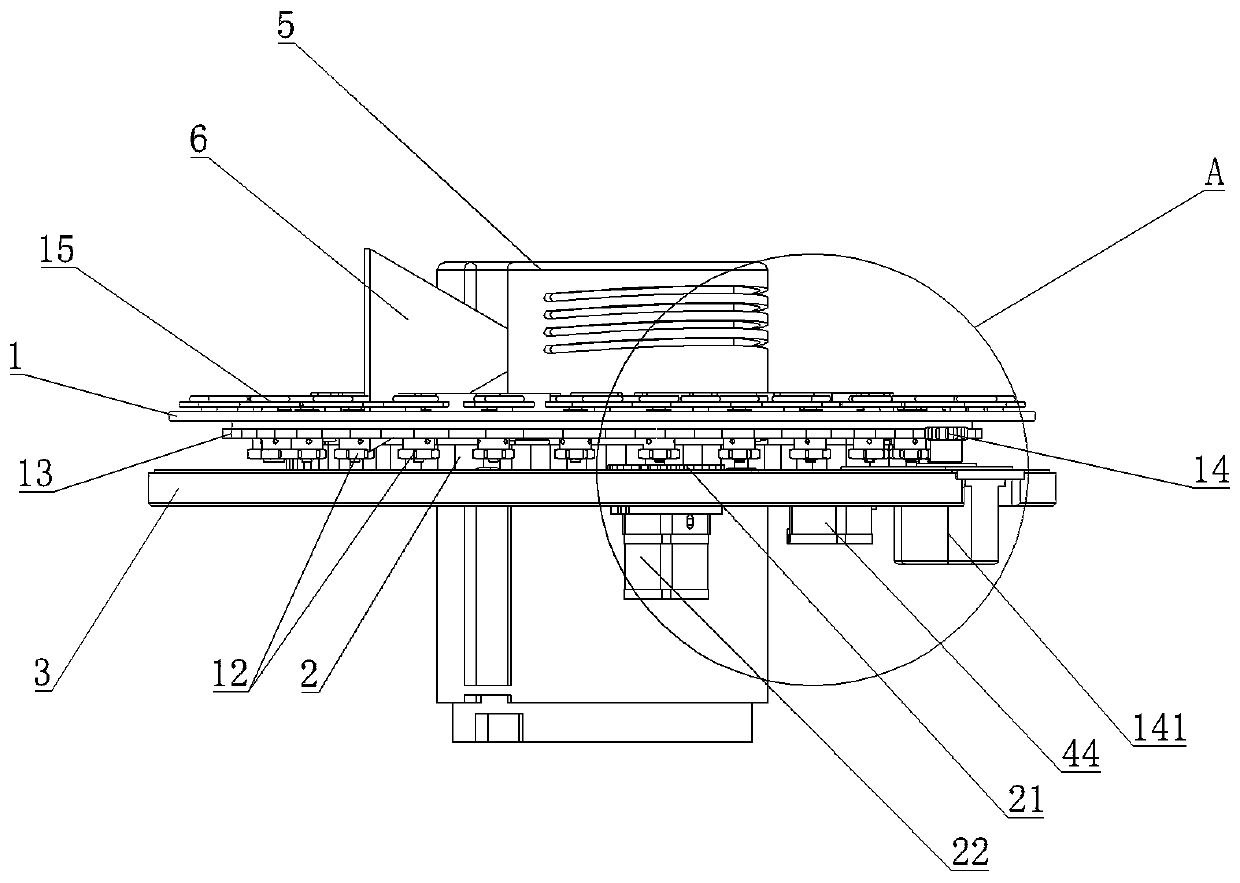

[0030] Example 1: as attached Figure 1-13 As shown, a reagent disk magnetic bead mixing device includes an outer disk 1, the bottom of the outer disk 1 is provided with a first gear 2, the upper part of the outer disk 1 is provided with a plurality of mixing seats 11, the mixing seats 11 A second gear 12 is connected, the second gear 12 is meshed with the first gear 2 , the first gear 2 is meshed with a third gear 21 , and the third gear 21 is connected with a first driving device 22 . The first driving device 22 drives the third gear 21 to rotate, the third gear 21 drives the first gear 2 to rotate, the first gear 2 drives the mixing base 11 to rotate, and the mixing base 11 contains the reagent mixed with magnetic beads, which needs to be adjusted. When the magnetic beads are mixed, it is only necessary to open the first drive device, and the mixing seat will rotate independently to mix the magnetic beads.

[0031] like Image 6 and Figure 9 As shown, the mixing seat 11...

Embodiment 2

[0041] Example 2: as Figure 1-13 As shown, the second driving device 141 and the third driving device 44 are turned on; the second driving device 141 drives the fifth gear 14 to rotate, the fifth gear 14 drives the fourth gear 13 to rotate, the fourth gear 13 drives the entire outer disk 1 to rotate, and the outer disk 1 Rotate to the sample adding position, and at the same time the inner disk 4 is also transferred to the sample adding position driven by the third drive device 44; turn on the first drive device 22, the first drive device 22 drives the third gear 21 to rotate, and the third gear 21 drives the first drive device 21 to rotate. A gear 2 rotates; the first gear 2 drives the second gear 12 meshed with it to rotate; the second gear 12 drives the mixing base 11 to rotate, and the magnetic beads in the mixing base 11 are mixed. , the barcode scanner 6 scans the barcode of the reagent in the mixing seat 11; the sample adding needle adds the sample. Such a design allow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com