Method for uniformly mixing by adopting magnetic materials

A magnetic material and mixing technology, applied in the field of medical testing, can solve the problems of no disclosed method for mixing magnetic materials, complex structure, etc., and achieve the effects of good reaction results, simple and controllable methods, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Embodiment 1: The method for mixing with magnetic materials specifically includes the following steps:

[0029](1) Choose a spherical mixing rotor made of iron as a magnetic material, with a diameter of 0.5mm, 10 pieces in total, ready to use;

[0030](2) Place the mixing rotor in the containing cavity containing the reaction solution;

[0031](3) A magnetic field is applied to the outside of the accommodating cavity, and the magnetic field is used to control the movement of the magnetic field position or / and control the strength of the magnetic field or / and control the direction of the magnetic field so that the mixing rotor is in the accommodating cavity The two ends of the inner part or the middle part of the containing cavity and the two ends of the containing cavity perform the physical movement back and forth, and the physical movement mode is rotation or translation or bounce; so as to achieve the effect of the substance in the liquid The purpose of mixing;

[0032]The specific rea...

Embodiment 2

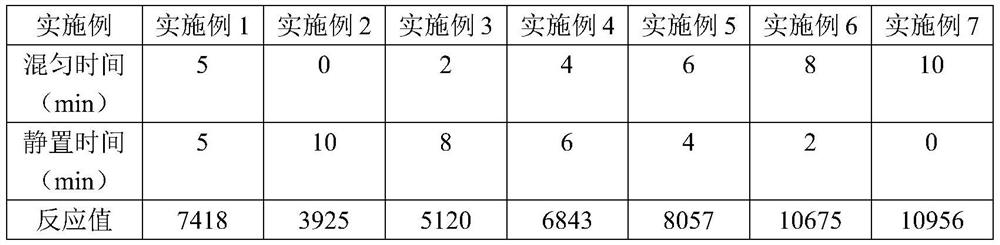

[0033]Examples 2-7 all adopt the method of mixing with magnetic materials in the above-mentioned Example 1; the difference from Example 2 is that the mixing time and the standing time are different, and the reaction value is detected by the instrument immediately after the reaction. The measured Cy5 fluorescence values are shown in Table 1.

[0034]Table 1 Cy5 fluorescence values measured after the reactions in Examples 1-7

[0035]

[0036]It can be seen from Table 1 that the Cy5 fluorescence value measured after the reaction shows that the magnetic bead mixing can promote the antigen-antibody binding reaction. The longer the mixing time, the higher the reaction value. Among them, the reaction value is basically after 8 min. If it is stable, increase the mixing time, the reaction value will not increase much.

Embodiment 8

[0037]Embodiment 8: The difference from Embodiment 1 is that it also includes using Teflon for surface treatment on the surface of the mixing rotor to avoid adsorption;

[0038]The method for mixing with magnetic materials specifically includes the following steps:

[0039](1) Choose a spherical mixing rotor made of iron as a magnetic material, with a diameter of 0.5mm, 10 pieces in total, ready to use; Teflon is used for surface treatment on the surface of the mixing rotor to avoid adsorption;

[0040](2) Place the mixing rotor in the containing cavity containing the reaction solution;

[0041](3) A magnetic field is applied to the outside of the accommodating cavity, and the magnetic field is used to control the movement of the magnetic field position or / and control the strength of the magnetic field or / and control the direction of the magnetic field so that the mixing rotor is in the accommodating cavity The two ends of the inner part or the middle part of the containing cavity and the two e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com