Polarizing beam splitter, manufacturing method thereof, and polarization beam splitting method

A polarization beam splitter, polarization extinction ratio technology, applied in instruments, optical components, optics, etc., can solve the problems of wide bandwidth, narrow bandwidth, size limitation, etc., and achieve the effect of flexible size and symmetrical output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Based on this, after determining the number of layers and the thickness of optical film material, Dove prism material, coating film, the present invention further provides a kind of preparation method of above-mentioned polarization beam splitter, comprises the steps:

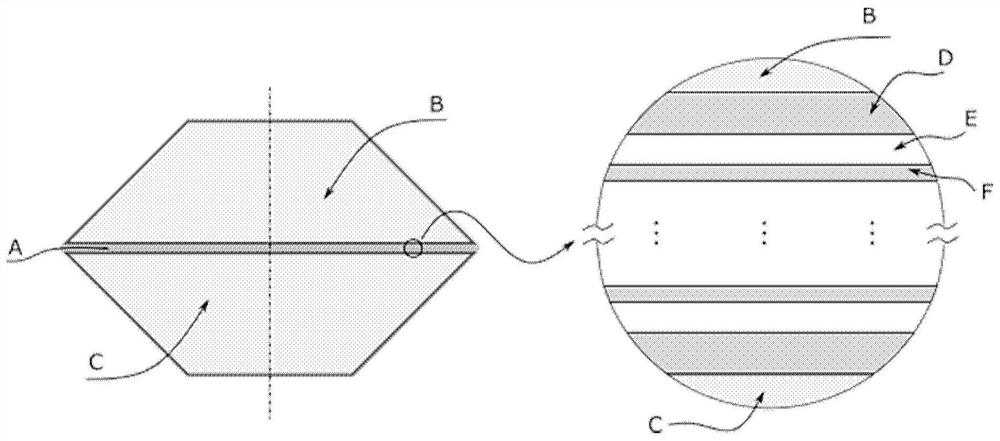

[0046] The multilayer optical film A is divided into two parts, which are respectively coated on the bottom surfaces of two Dove prisms B and C to form a image 3 the structure shown;

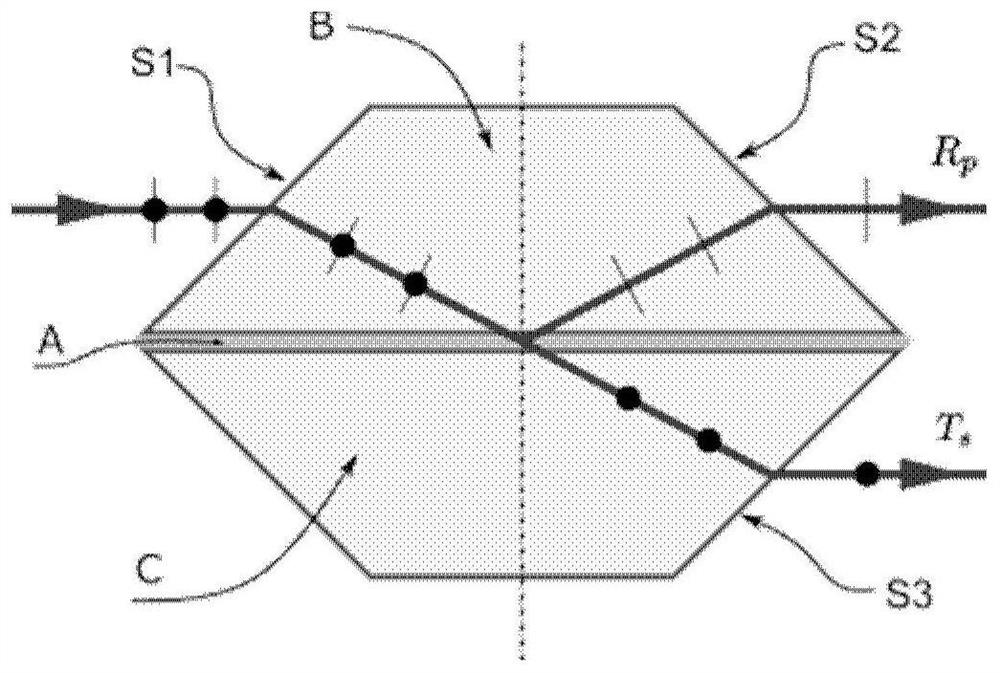

[0047] Then the bottom surfaces of the two coated Dove prisms are facing each other, and assembled into such a figure 1 Polarizing beam splitter shown.

[0048] Among them, due to the requirements of the bonding process, the optical surface shape of the bottom surface of the Dove mirror has certain requirements, and generally needs to reach the order of λ / 10, where λ is the typical wavelength of the polarizing device.

Embodiment 1

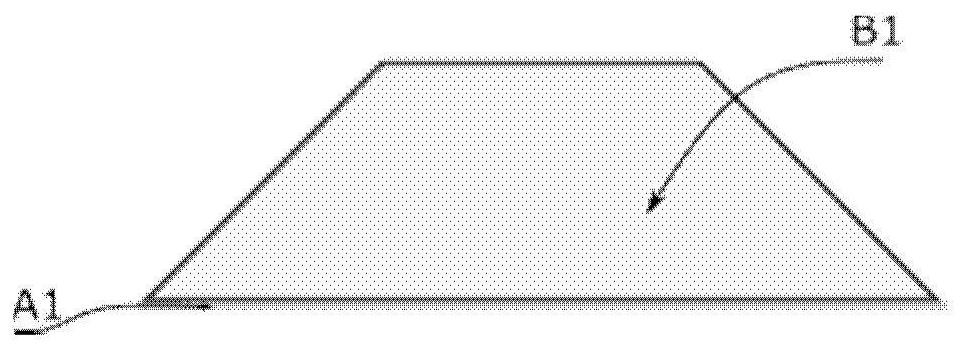

[0053] High performance PBS from UV to NIR (350nm–1800nm). Two Dove prisms coated on the bottom surface are assembled into a component using photoresist or gluing process. The two bottom surfaces need photoresist in the subsequent process, so the precision of the processed surface needs to be relatively high, reaching λ / 10, and other light-transmitting surfaces such as the incident surface, exit surface and top surface can reach λ / 4. The two trapezoidal faces are opaque, so there is no face shape requirement. The base material of the Dove prism is Al 2 o 3 . The Dove prism of this embodiment adopts typical dimensions, the bottom surface is 44.94mm long and 12.7mm wide, the top surface is 19.54mm long and 12.7mm wide, and the height between the bottom surface and the top surface is 12.7mm. Scale scales the size. The dimensions are for Al 2 o 3 The base can make the parallel light incident from the midpoint of the hypotenuse of the trapezoid approximately reach the midpoi...

Embodiment 2

[0059] If Ta 2 o 5 Replace ZrO 2 As a material with a high refractive index, this embodiment gives the corresponding coating parameters. Ta 2 o 5 Refractive index curve see Figure 11 , Figure 12 and Figure 13 is to use Ta 2 o 5 Rs and Tp as a function of wavelength for high refractive index films. Among them, initial refers to the film thickness according to the previous embodiment 1, and optimized refers to the film thickness according to Ta 2 o 5 The results of the film thickness optimization of the refractive index. The optimized film thickness is shown in Table 2.

[0060] Table 2

[0061]

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com