Linear polarization quasi-continuous fiber laser

A fiber laser and linear polarization technology, applied in the laser field, can solve the problems of non-adjustable peak pulse width and inability to meet the precision processing requirements of high-reflection materials, etc., and achieve the effect of increasing output power, increasing polarization effect ratio, and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

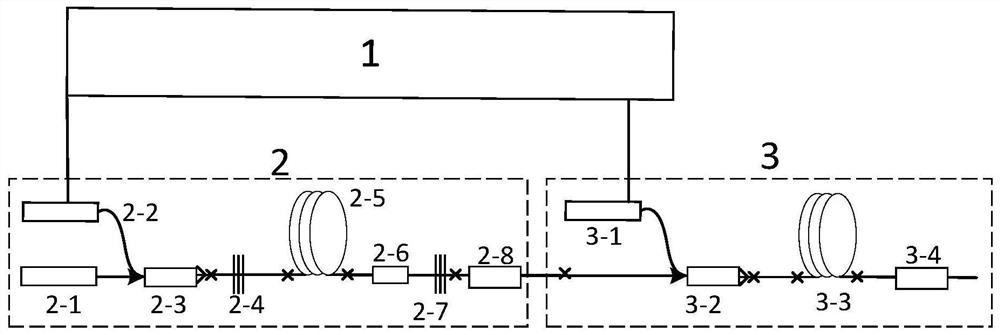

[0025] A linearly polarized quasi-continuous fiber laser is composed of an electric control drive module 1, a linearly polarized laser module 2 and a laser amplification module 3 in sequence.

[0026] The linearly polarized laser module 2 includes an indicating light device 2-1, N pump lasers 2-2, a first polarization maintaining beam combiner 2-3, a polarization device 2-6, a polarization maintaining high reflection grating 2-4, a polarization maintaining Low reflection grating 2-7, first polarization maintaining gain fiber 2-5, first stripper 2-8. The output end of the indicating light device 2-1 is fused with the signal input end of the first polarization-maintaining beam combiner 2-3; the first polarization-maintaining beam combiner 2-3 has N+1 input optical fibers, and the N pump lasers 2-2 are fused with N input fibers of the first polarization-maintai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com