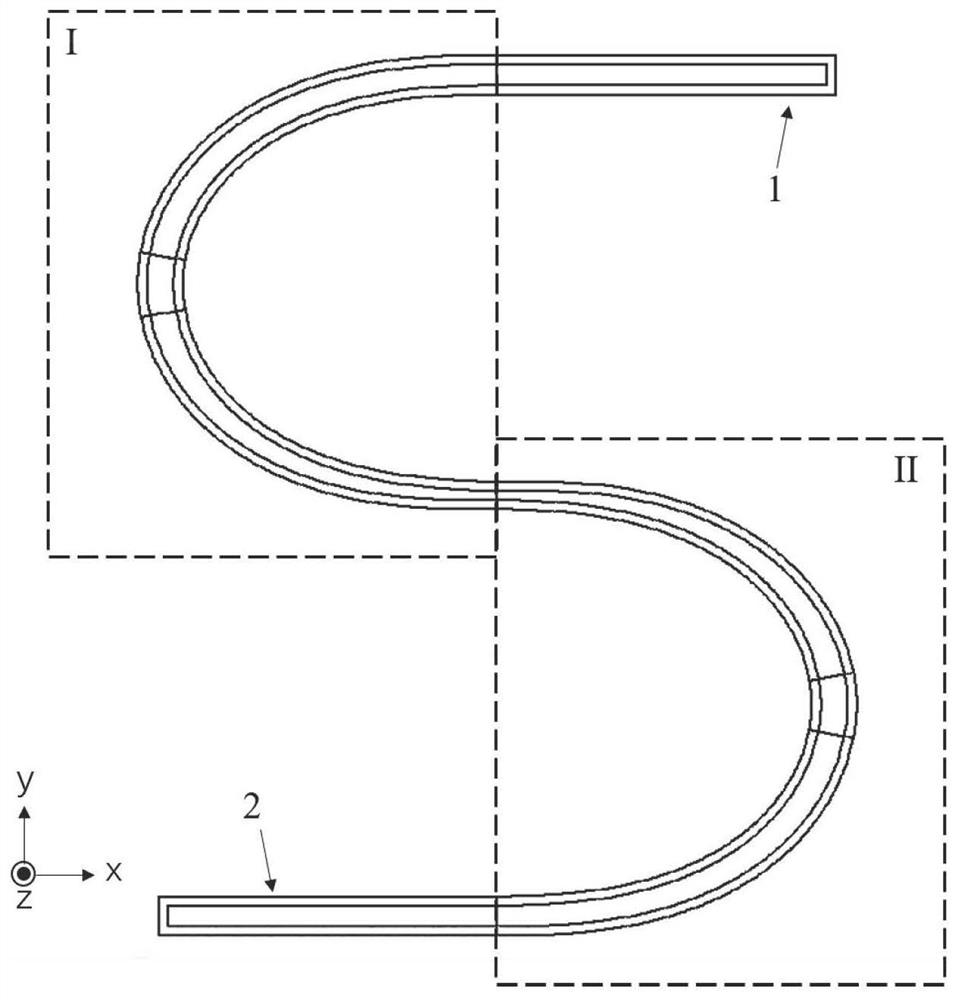

Cascaded bent waveguide type lithium niobate polarization rotator

A polarization rotator and bending waveguide technology, applied in the field of optical communication, can solve the problems of large size, reduction, and large inclination angle of the sidewall of the etched waveguide, such as an integrated polarization control device, etc. The effect of simplifying the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

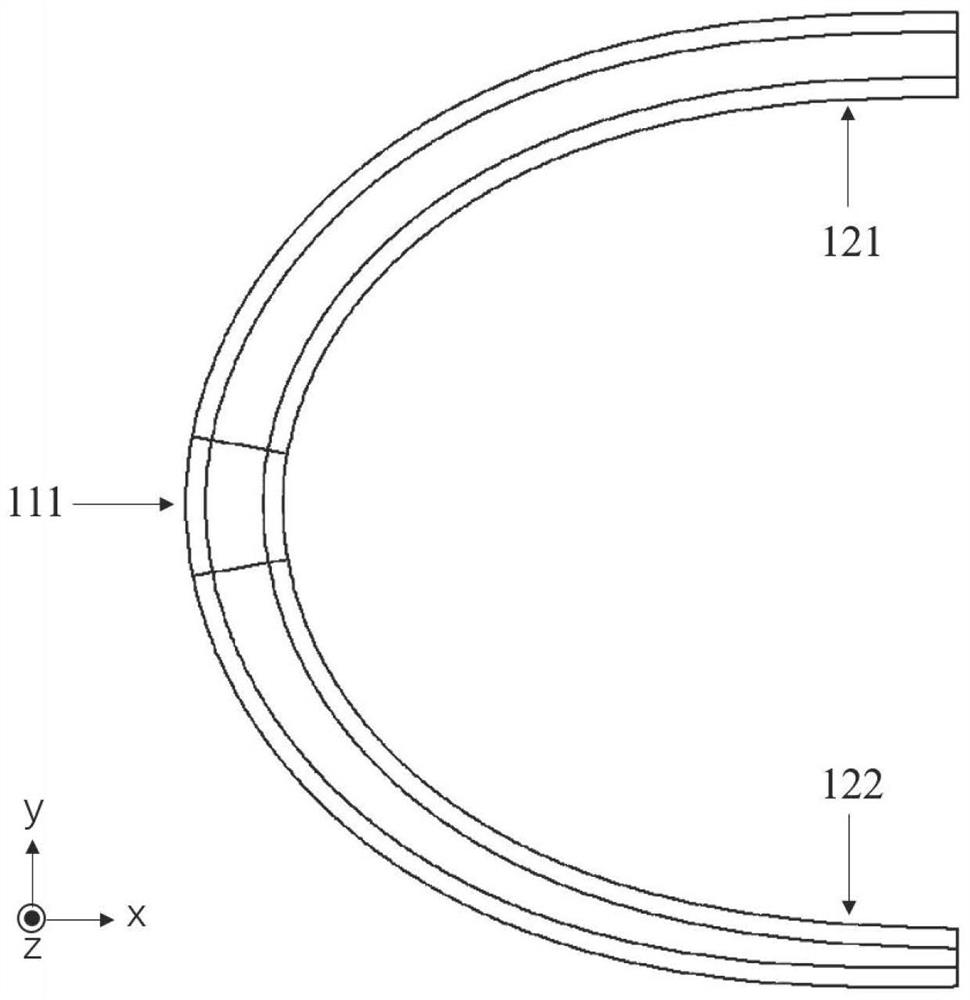

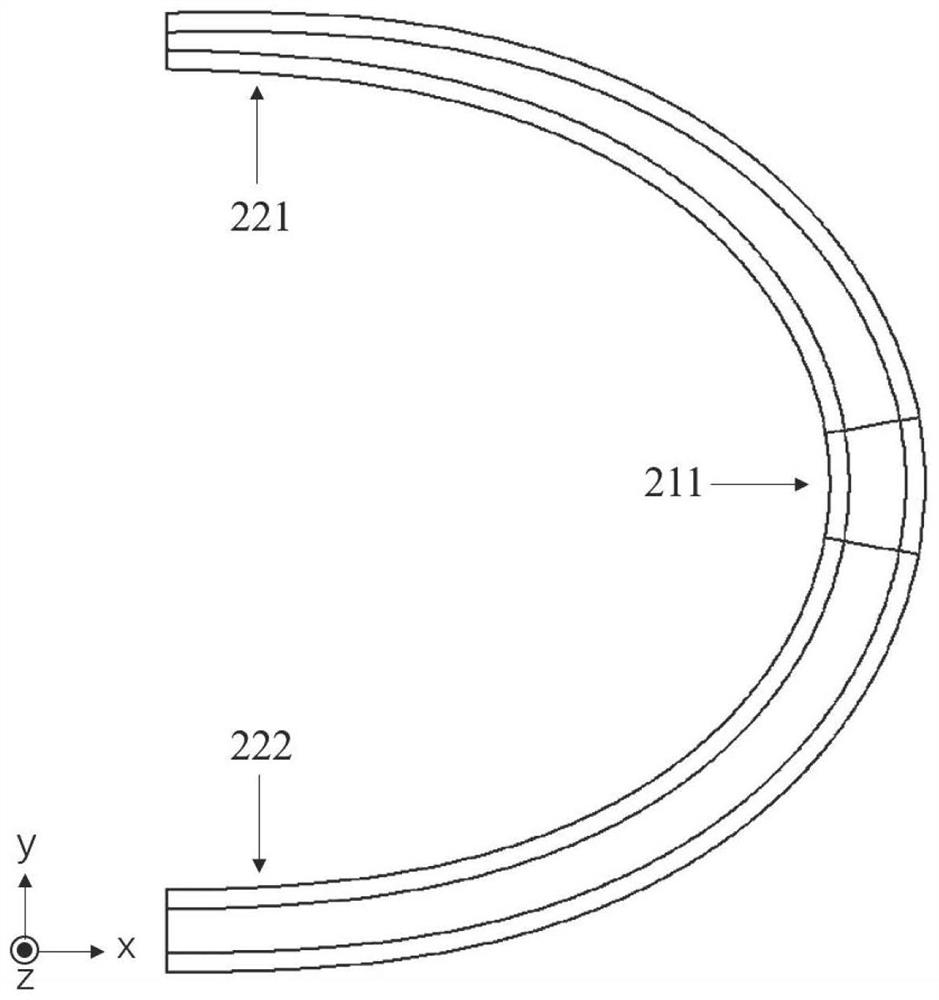

[0038]X-cut lithium niobate based on lithium niobate on silicon insulator (Lithium Niobate on Insulator, LNOI) is selected, the core layer is lithium niobate material, the thickness is 600nm, and the refractive index is (2.138 in x direction, 2,211 in y direction, z Direction 2,211); the thickness of the silicon dioxide buried layer is 1.445; the refractive index of the air upper cladding is 1; the thickness of the silicon substrate layer is 500 μm, and the refractive index is 3.476. The etching depth of the etched waveguide is 600nm, the inclination angle of the sidewall of the waveguide is 65 degrees, and the lithium niobate waveguide transmits the fundamental mode of mixed polarization of TE and TM.

[0039] The maximum bending radius of the Euler curved waveguides 121 and 222 with gradually changing width is 45 μm, the minimum bending radius is 5 μm, and the waveguide width gradually changes from 620 nm to 810 nm; the maximum bending radius of the Euler curved waveguides 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com