Polarizer based on guided wave resonance

A waveguide resonance and polarizer technology, applied in the field of polarizers and polarizers with high polarization extinction ratio, can solve the problems of performance differences, limit the application range of devices, and reduce device performance, etc., and achieve low light intensity loss and small insertion loss , The effect of reducing insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

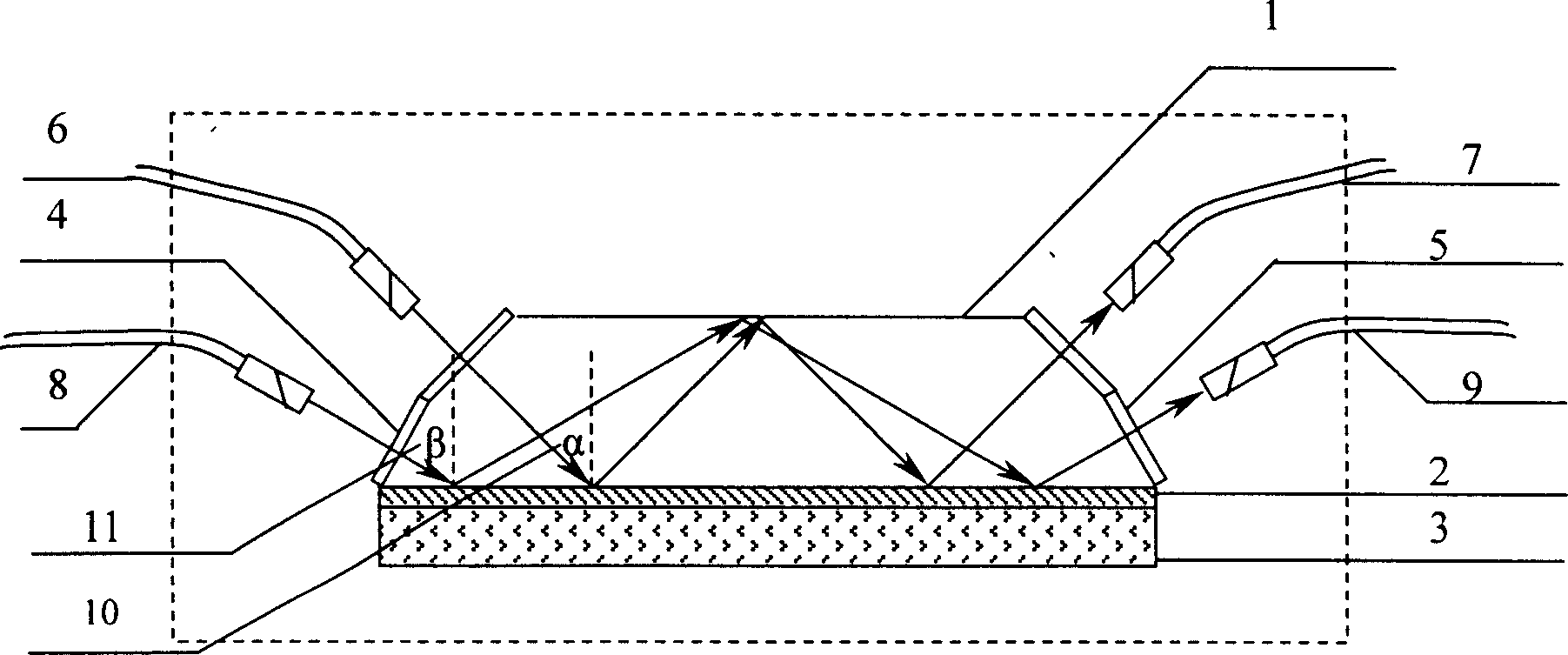

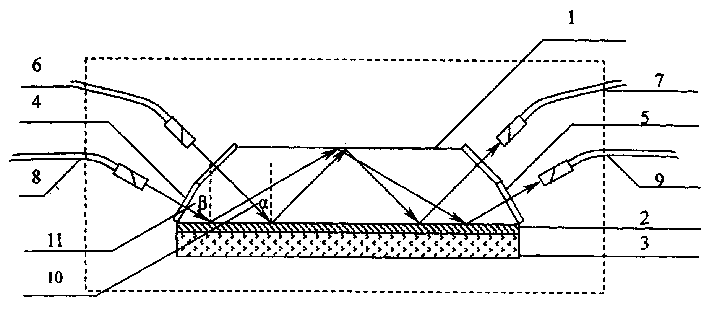

[0027] The polarizer of the present invention is composed of an elongated prism 1, a bottom metal film 2, a dielectric film 3, and an antireflection film 4, 5, the elongated prism 1, the bottom metal film 2, and the dielectric film 3 are arranged from top to bottom, and the antireflection film 4, 5 Plated on both sides of the elongated prism 1, the metal film 2 on the bottom and the dielectric film 3 form a single-sided metal clad waveguide structure, the dielectric film 3 is the wave guiding layer, and the metal film 2 on the bottom is the cladding layer. Import and export fiber joints 6, 7, 8 and 9 lead the laser beam into or out of the polarizer, wherein the fiber joints 6, 7 are symmetrical with respect to the elongated prism 1, and the optical fiber joints 8 and 9 are symmetrical with respect to the elongated prism 1, and they are symmetrical to the elongated prism 1. The inclination angles of the bottom surface are respectively 47.4 and 35.8 degrees, and are respectively ...

Embodiment 2

[0032] The polarizer of the present invention is composed of an elongated prism 1, a bottom metal film 2, a dielectric film 3, and an antireflection film 4, 5, the elongated prism 1, the bottom metal film 2, and the dielectric film 3 are arranged from top to bottom, and the antireflection film 4, 5 Plated on both sides of the elongated prism 1, the metal film 2 on the bottom and the dielectric film 3 form a single-sided metal clad waveguide structure, the dielectric film 3 is the wave guiding layer, and the metal film 2 on the bottom is the cladding layer. Import and export fiber joints 6, 7, 8 and 9 lead the laser beam into or out of the polarizer, wherein the fiber joints 6, 7 are symmetrical with respect to the elongated prism 1, and the optical fiber joints 8 and 9 are symmetrical with respect to the elongated prism 1, and they are symmetrical to the elongated prism 1. The inclination angles of the bottom surface are respectively 47.15 and 38.9 degrees, and are respectively...

Embodiment 3

[0037] The polarizer of the present invention is composed of an elongated prism 1, a bottom metal film 2, a dielectric film 3, and an antireflection film 4, 5, the elongated prism 1, the bottom metal film 2, and the dielectric film 3 are arranged from top to bottom, and the antireflection film 4, 5 Plated on both sides of the elongated prism 1, the metal film 2 on the bottom and the dielectric film 3 form a single-sided metal clad waveguide structure, the dielectric film 3 is the wave guiding layer, and the metal film 2 on the bottom is the cladding layer. Import and export fiber joints 6, 7, 8 and 9 lead the laser beam into or out of the polarizer, wherein the fiber joints 6, 7 are symmetrical with respect to the elongated prism 1, and the optical fiber joints 8 and 9 are symmetrical with respect to the elongated prism 1, and they are symmetrical to the elongated prism 1. The inclination angles of the bottom surface are respectively 53.0 and 42.65 degrees, and are respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com