Pickup pocket bucket loader for vending machine

A technology of automatic vending machines and bucket carts, which is applied to instruments, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items. Direct drop and other problems, to achieve the effect of increasing the installation position and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

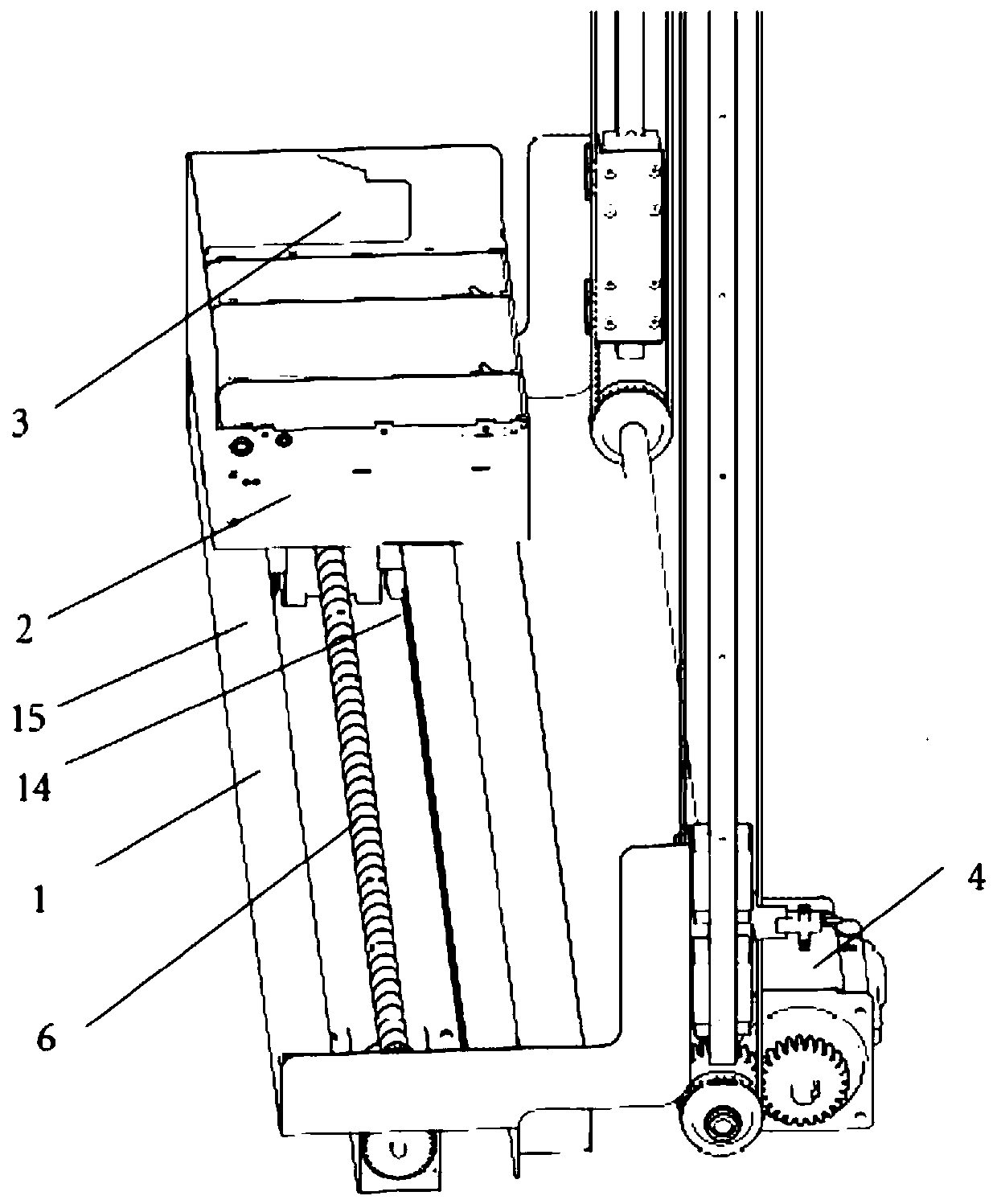

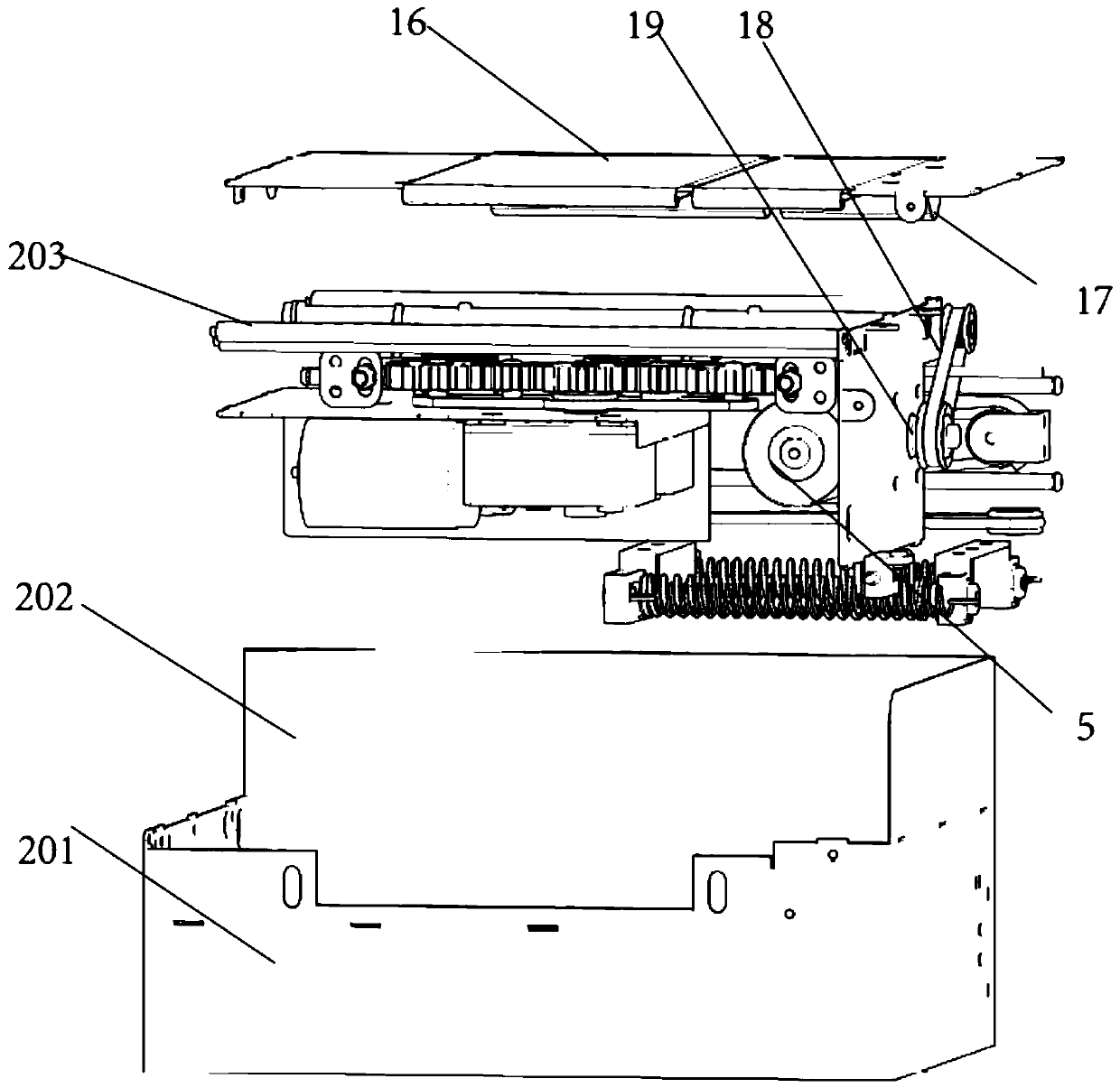

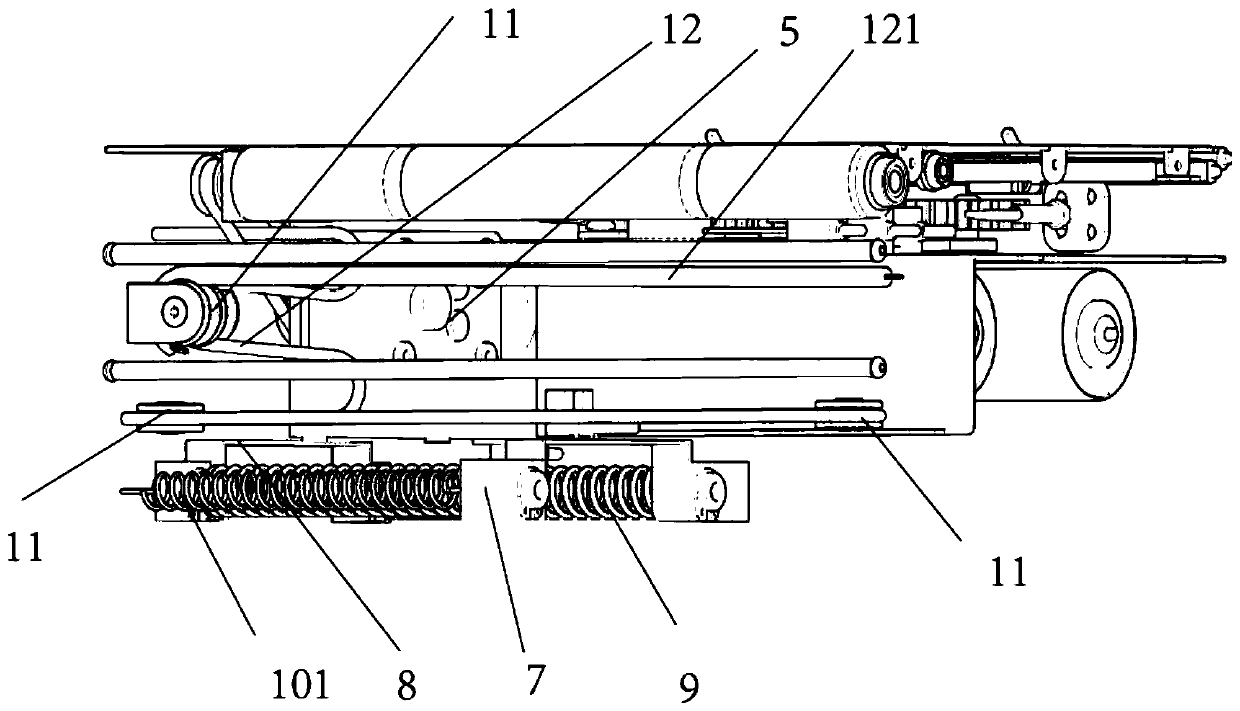

[0027] refer to Figure 1-Figure 5 , a bucket cart for picking up goods from a vending machine, including a horizontal guide rail 1, a goods rack 2, a Y-axis drive mechanism that drives the transverse guide rail 1 and the goods rack 2 to move in the vertical direction, and drives the goods rack 2 on the transverse guide rail 1. The X-axis drive mechanism that moves horizontally, and the push plate 3 that moves horizontally on the top surface of the goods rack 2; when it is necessary to accept commodities of different heights from the vending machine, the Y-axis drive mechanism drives the vending machine to pick up the goods The cargo rack 2 in the bucket cart moves up and down, and when it is necessary to accept commodities at different horizontal positions, the X-axis d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com