Gas density relay

A technology of gas density and relay, applied in the direction of circuits, electric switches, electrical components, etc., can solve problems such as oil leakage or air leakage, affect normal use, and user loss, achieve excellent sealing performance, prolong service life, and expand application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

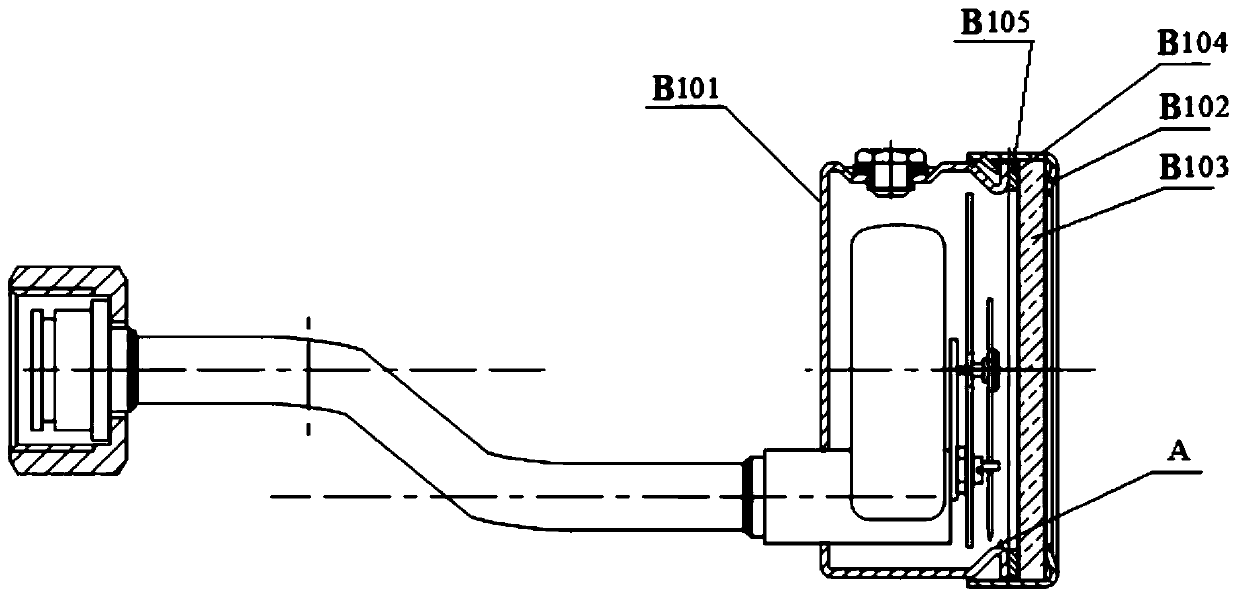

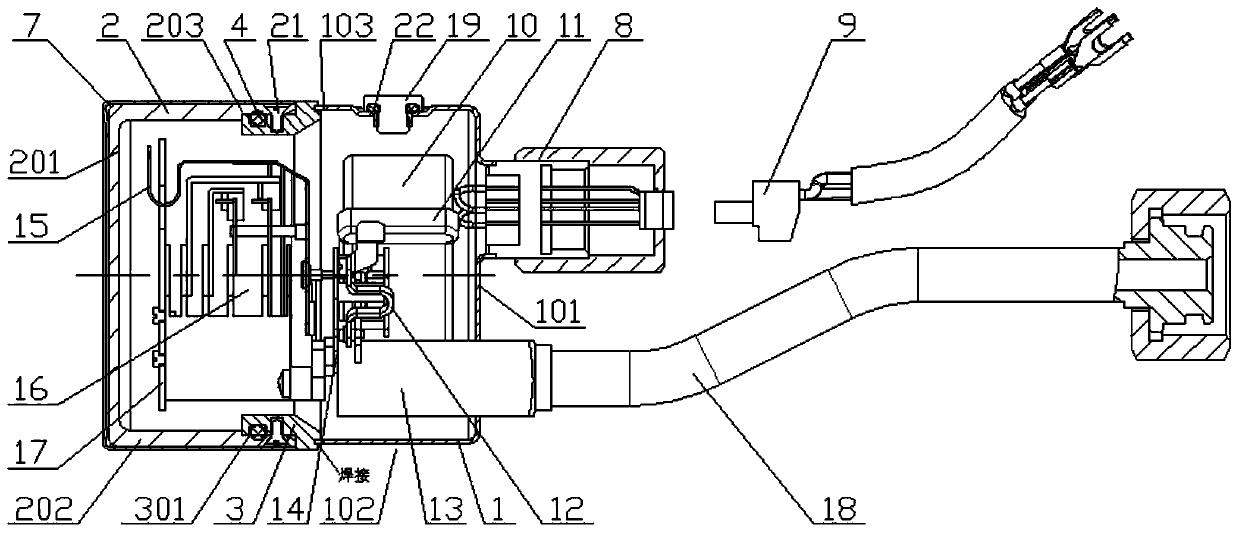

[0032] Such as figure 2 As shown, a gas density relay includes a watch case and a dial 17 arranged inside the watch case, a base 13, a pressure detector 10, an end seat 11, a temperature compensating element 12, a movement 14 and a pointer 15; it also includes Alarm blocking signal contact 16, wire socket 8, cable 9 and joint assembly 18.

[0033]The watch case includes a case 1, an observation window 2 and a sealed transition piece 3; the case 1 is in the shape of a cylinder; the case 1 includes a case bottom wall 101 and a case side wall 102, and the case bottom wall 101 and the case side wall 102 is surrounded by a cylindrical shape with an open end; the observation window 2 is a cylindrical shape; the observation window 2 includes an observation window front wall 201 and an observation window side wall 202, and the observation window front wall 201 and the observation window side wall 202 are surrounded by an end Open cylindrical shape; the sealing transition piece 3 is ...

Embodiment 2

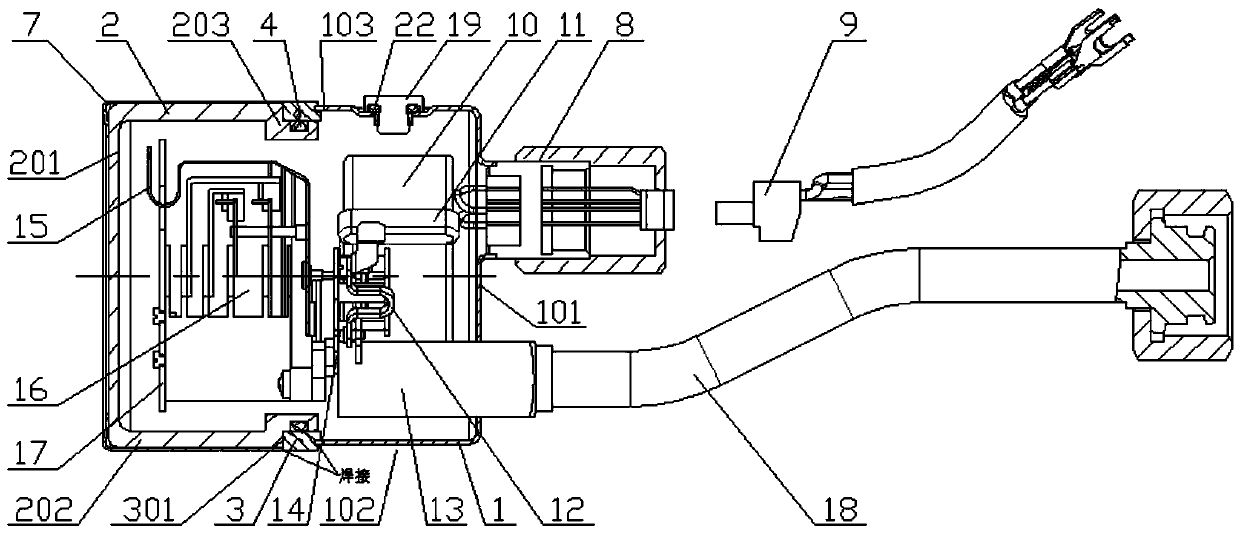

[0041] Such as image 3 As shown, a gas density relay, the outer side of the observation window 2 is provided with a first groove 301, the first sealing ring 4 is placed in the first groove 301, the opening end 203 of the observation window is in contact with the sealing transition piece 3, and the observation window 2 forms a sealed air chamber with the sealing transition piece 3, the first sealing ring 4 and the housing 1. Other parts are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0043] Such as Figure 4 As shown, a gas density relay, the inner side of the sealing transition piece 3 is provided with a first groove 301, the first sealing ring 4 is placed in the first groove 301, the opening end 203 of the observation window is in contact with the sealing transition piece 3, and the observation The window 2 forms a sealed air chamber with the sealing transition piece 3 , the first sealing ring 4 and the housing 1 . At the same time, it also includes glass 20 (generally safety glass or toughened glass). The observation window front wall 201 is a transparent material, the observation window front wall 201 is provided with a second groove 204, the second sealing ring 23 is placed in the second groove 204, the glass 20 is connected with the observation window front wall 201 and the second sealing ring 23 touch. The glass 20 is fixed on the sealing transition piece 3 through the watch cover 7 and the observation window 2 , or is fixed on the open end 103 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com