Radial sealing method for fiber of digitalized optical transmission towing line array

A dragging line array and radial sealing technology, which is applied in the field of dragging line arrays, can solve the problems of optical contact surface work of optical connection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method of the present invention will be described in detail below in conjunction with the drawings and embodiments.

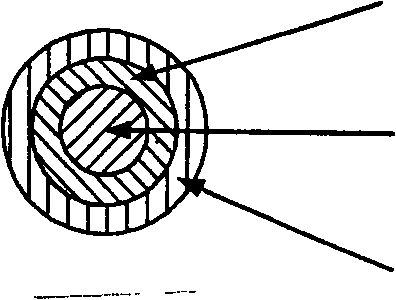

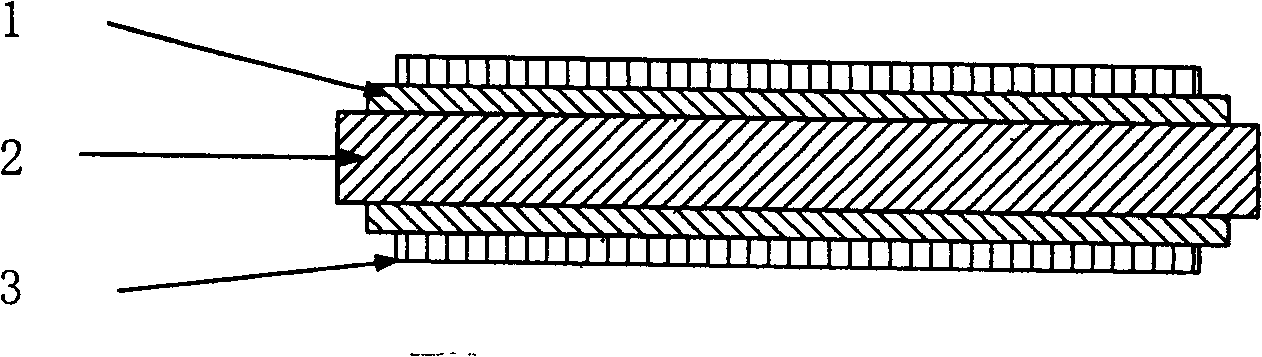

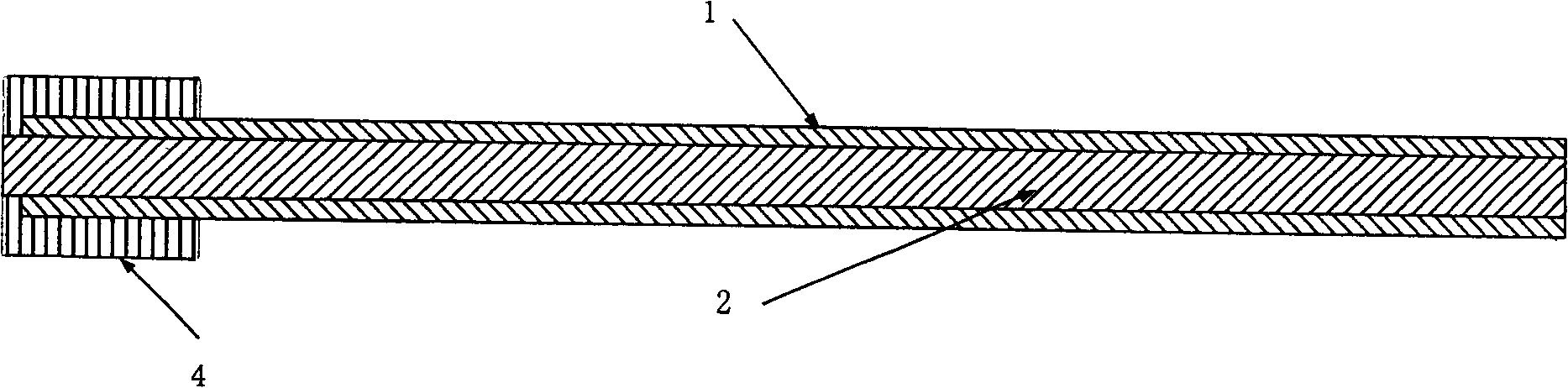

[0033] Referring to Fig. 1-6, Fig. 1-6 is also a flow chart of the production method of the present invention, and the specific steps include:

[0034] 1) Select an ordinary single-mode optical fiber with a length of 500 mm and a diameter of 0.9 mm, with an MTRJ optical connector 4 at one end, and its outer sheath 3 is made of plastic. Wipe the single-core bare fiber 2 with the coating layer 1 clean with absorbent cotton with anhydrous industrial alcohol;

[0035] 2) The polyurethane tube with a cutting length of 50 mm is the first oil-resistant casing 5, and the polyurethane tube with a cutting length of 420 mm is the second oil-resistant casing 10;

[0036] 3) Take the sealing cover 7 and the inner wall of the sealing tank 8 and wipe them clean with absorbent cotton dipped in industrial alcohol or acetone, put the first oil-resistant sleeve 5 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com