Connecting assembly and conductive terminal thereof

A technology for connecting components and conductive terminals, which is applied in the direction of connection, conductive connection, conductive connection, etc., can solve the problems of increased weight, shortened service life, and increased battery pack volume, and achieve the effect of stable signal acquisition and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings. However, this embodiment does not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to this embodiment are included in the protection scope of the present invention.

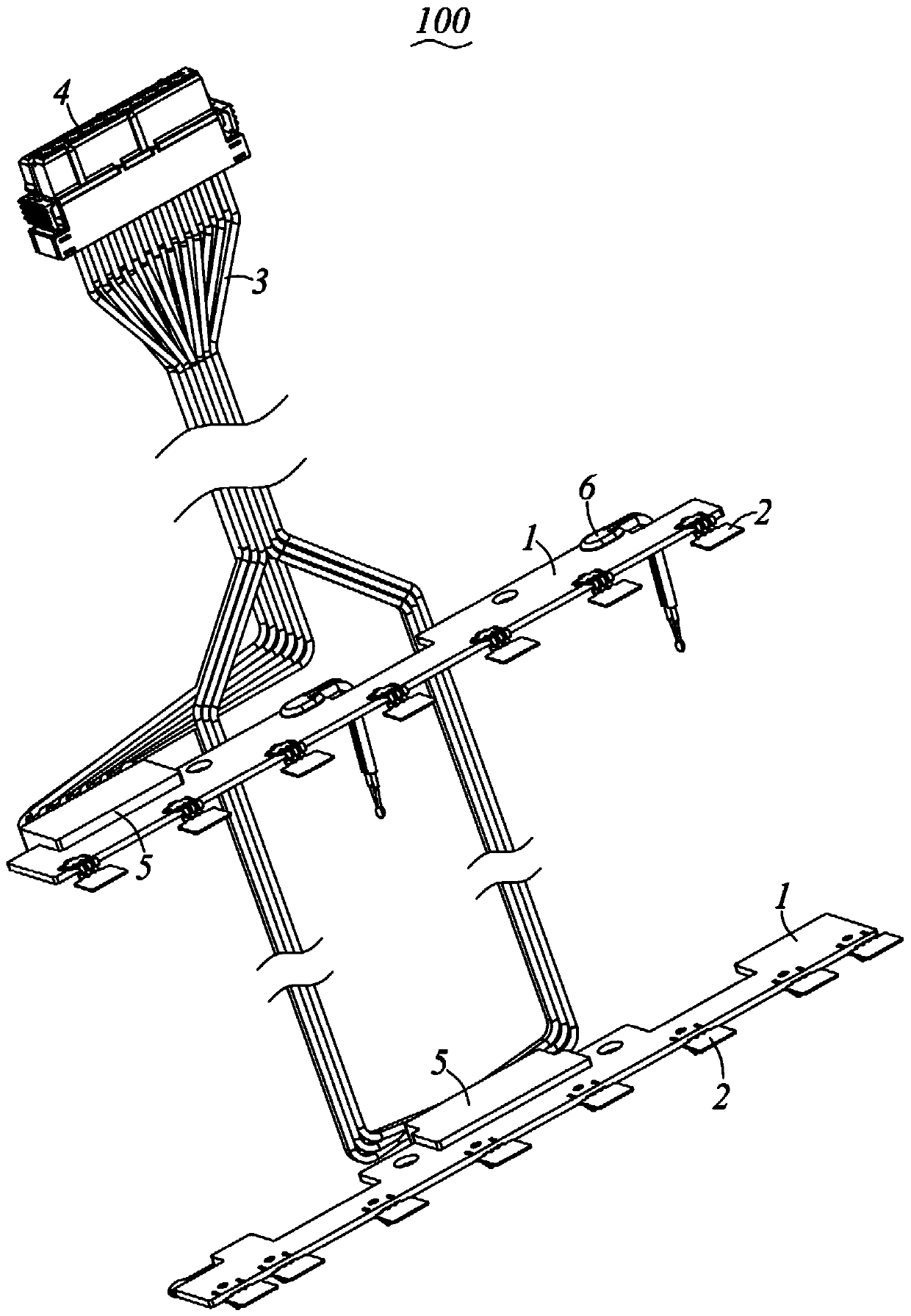

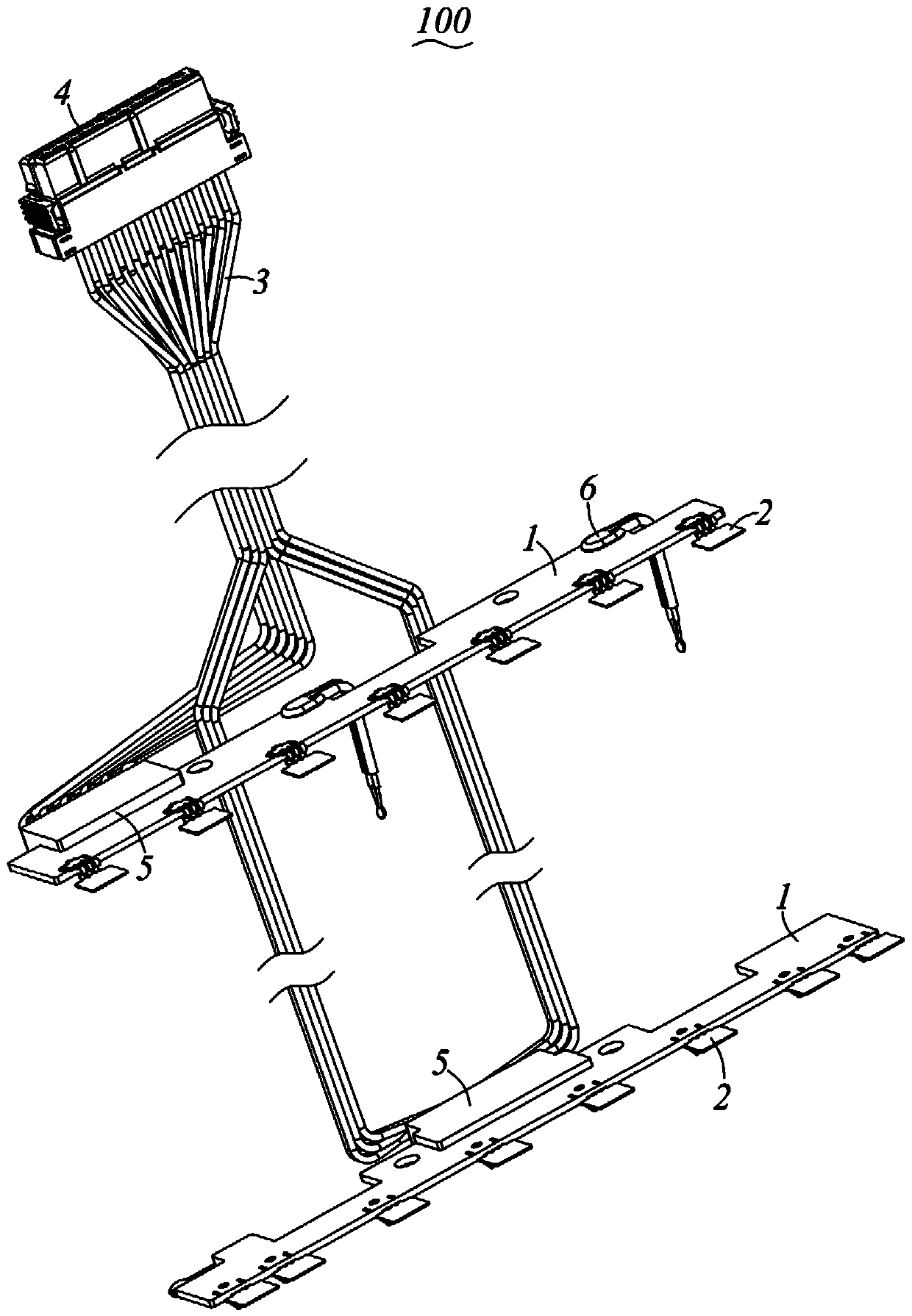

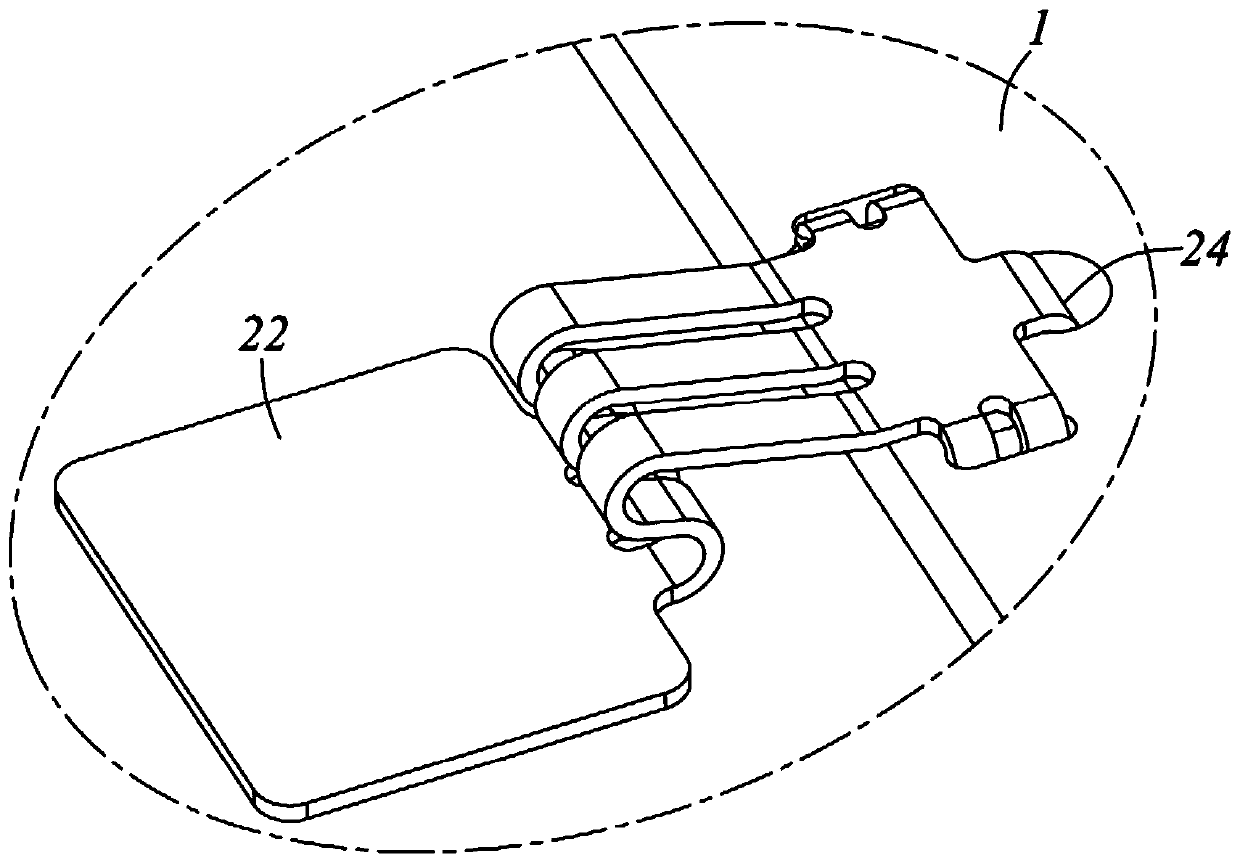

[0026] see Figure 1 to Figure 8 Shown is a preferred embodiment of the connection assembly 100 of the present invention. The connection assembly 100 is used to electrically connect between the battery pack and a battery management system to collect information such as voltage or temperature on the battery pack.

[0027] The connection assembly 100 includes a circuit board 1, a plurality of conductive terminals 2, a plurality of wires 3 and a connector 4 for connecting with the battery management system, and a plurality of the conductive terminals 2 are connected to one end of the circuit board 1 to communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com