Deburring process and deburring equipment for circuit board

A circuit board and deburring technology, applied in the directions of printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of short circuit, burnout, and components are not easy to be inserted into the holes of the circuit board, so as to save costs, promote recycling, improve The effect of the flush effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

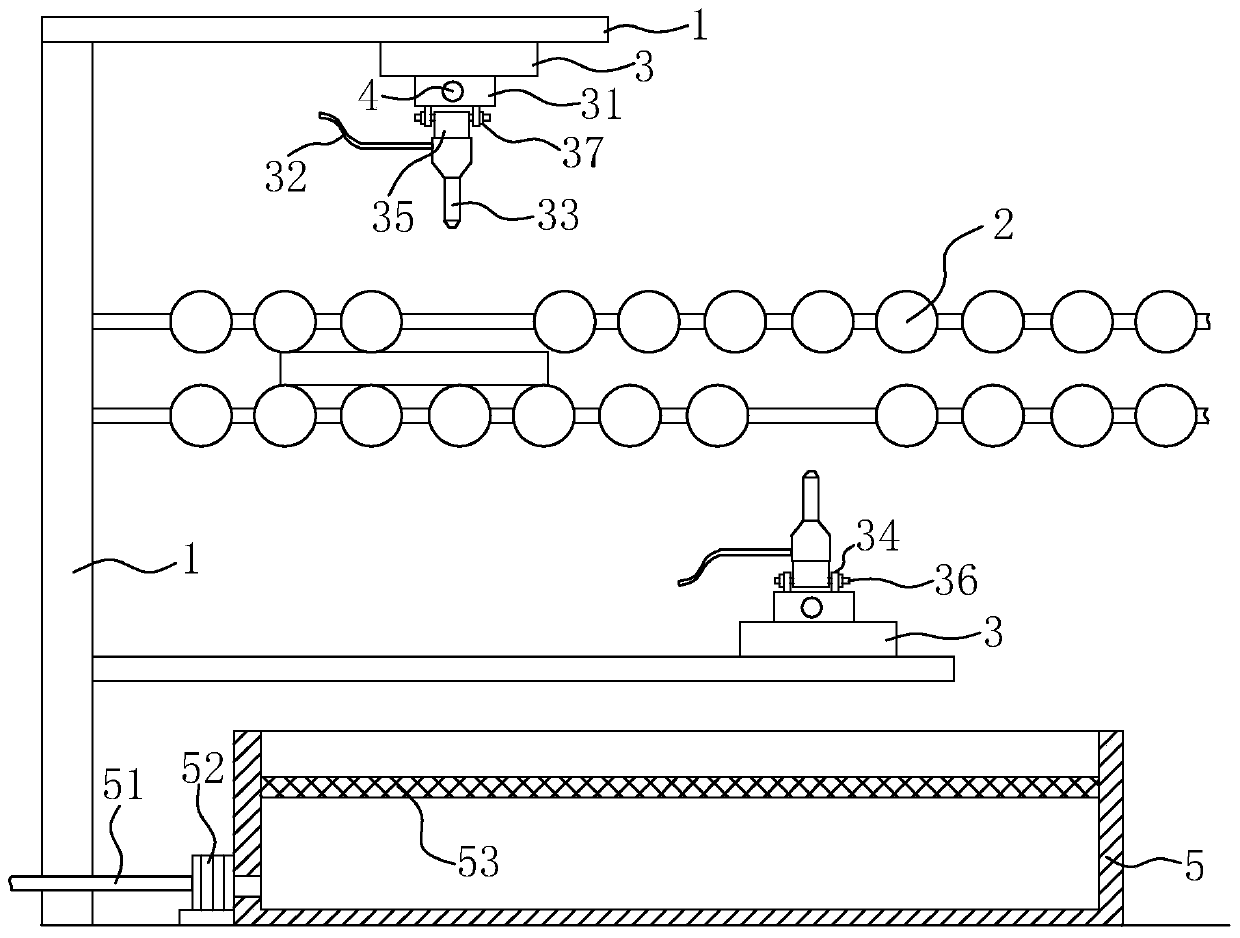

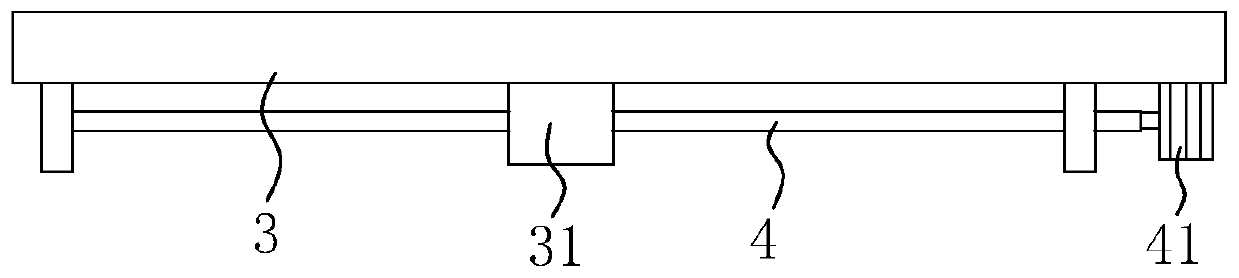

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] Present embodiment: a kind of circuit board deburring process, such as figure 1 and figure 2 shown, including the following steps:

[0038] Step 1: Use a deburring machine or auxiliary tools to process the burrs on the surface of the circuit board, so that the burrs or burrs adhered to the surface of the circuit board can be removed;

[0039] Step 2: Place the circuit board with the surface burr treated on the conveying device, and use the conveying device to convey the circuit board, so that the circuit board is conveyed along the predetermined direction;

[0040] Step 3: adjust the water spray device above and below the conveying device so that the water pressure of the water spray device above is between 8-12 MPa. The water pressure of the water spray device is adjusted so that the water pressure below is in the range of 4-6 MPa. In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com