Handheld saw for garden maintenance

A hand-and-garden technology, applied in the field of hand-held saws for garden maintenance, can solve problems such as fire, poor safety, wasted labor, etc., and achieve the effects of high safety, strong practicability and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

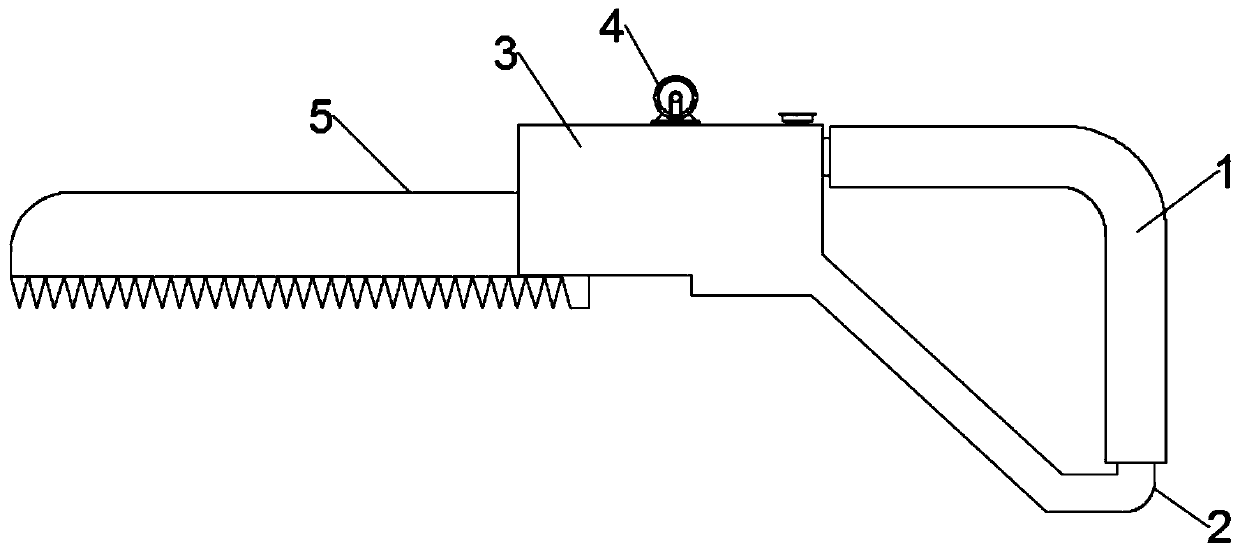

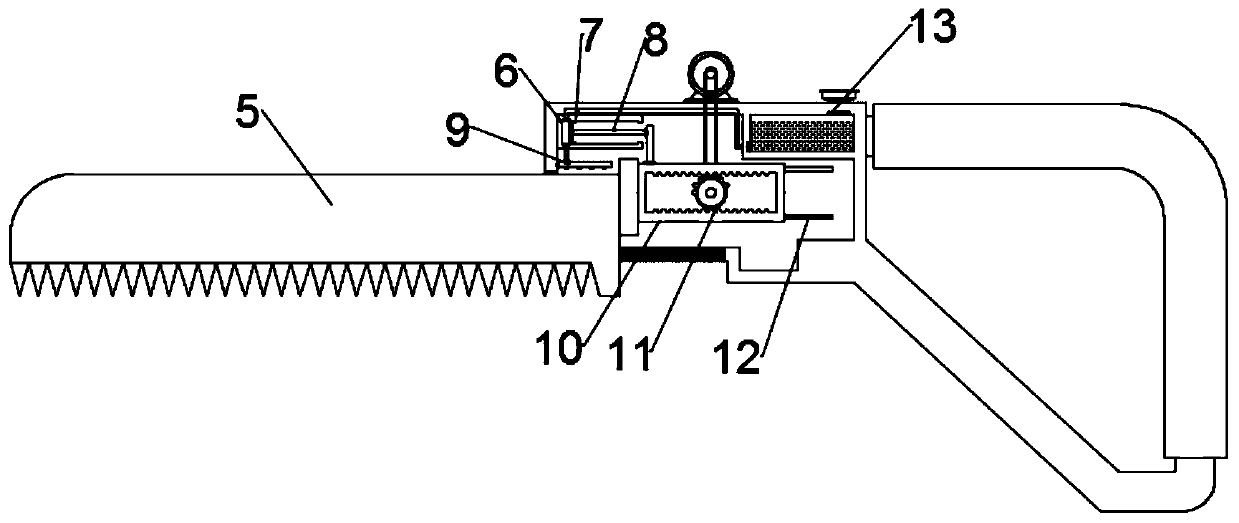

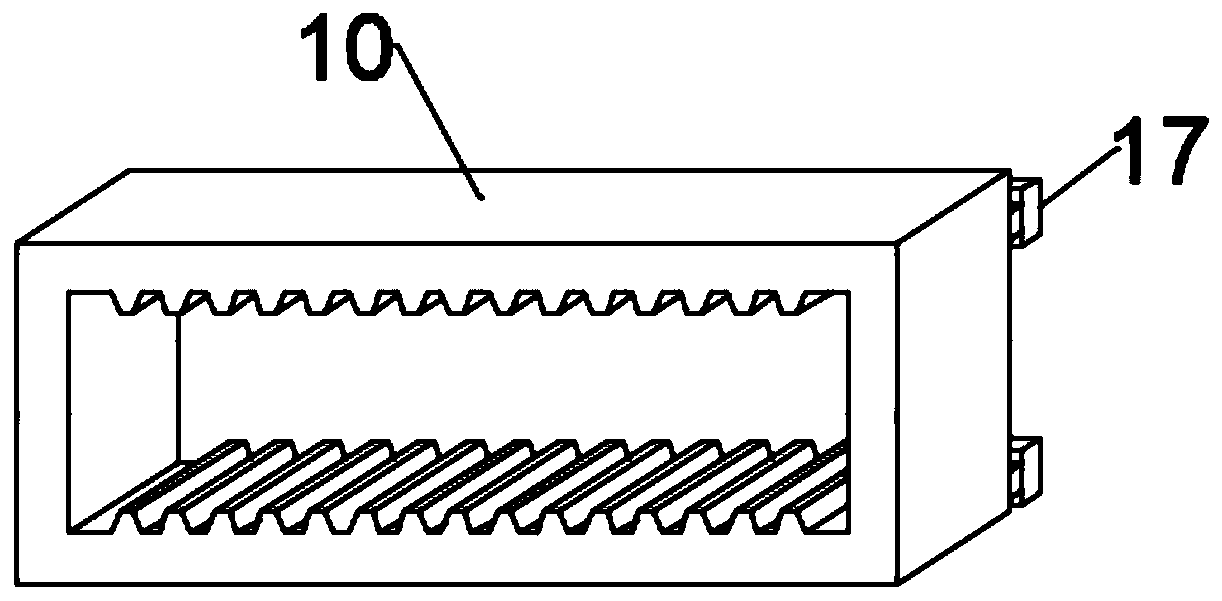

[0021] see Figure 1~3 , in an embodiment of the present invention, a hand-held saw for garden maintenance, including a handle 2, a drive chamber 3 and a saw blade 5; The other side end of the saw blade 5 is inserted into the drive cavity 3 and connected to the drive assembly arranged in the drive cavity 3, and the drive assembly drives the saw blade 5 to reciprocate to perform sawing processing. The inner side of the movable chamber 3 is also provided with a pumping mechanism. The pumping mechanism communicates with at least one spray head 9 installed in the driving chamber 3 and above the saw blade 5 through a conduit, and communicates with the water tank installed in the driving chamber 3 through another conduit. 13 is connected, when the pumping mechanism works, the water in the water tank 13 is pumped to the nozzle 9, and sprayed to the saw blade 5 through the nozzle 9, so as to prevent fires due to frictional heat when used in dry weather, and the safety is high.

[002...

Embodiment 2

[0028] see Figure 4 , the present invention also proposes another embodiment to improve the present application during the specific implementation process. Specifically, the handle 2 is arranged in a triangular structure, and one end of the handle 2 is hinged below the side end of the drive chamber 3, and the other end is A threaded sleeve 16 is installed for rotation, and the inner side of the threaded sleeve 16 is threadedly connected with a threaded rod 15 that is slidingly connected with the handle 2. Above the side end of the chamber 3, the adjustment of the threaded rod 15 is realized by turning the threaded sleeve 16, so as to realize the angle adjustment between the drive chamber 3 and the handle 2, thereby improving the convenience of use.

[0029] It should be noted that the sliding connection between the handle 2 and the threaded rod 15 in this embodiment means that the handle 2 and the threaded rod 15 do not rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com