Patents

Literature

40results about How to "Realize cooling operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

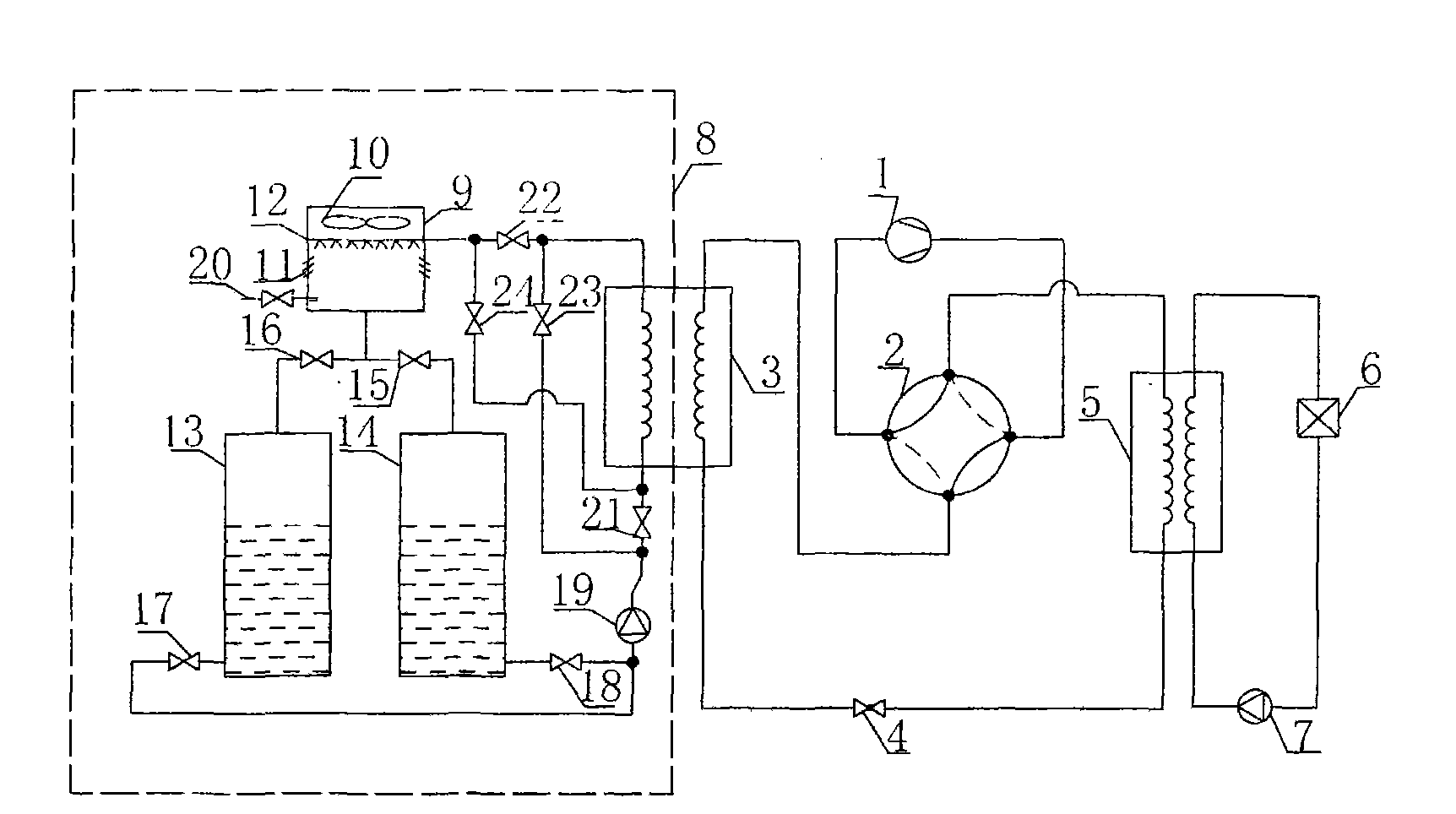

Novel air source heat pump air conditioner

ActiveCN101672500ALow costRealize cooling operationSpace heating and ventilation detailsCompression machines with reversible cycleRefrigeration compressorHigh energy

The invention relates to a novel air source heat pump air conditioner which comprises an air source heat pump consisting of a refrigeration compressor, a four-way reversing valve, a first heat exchanger, an expansion valve and a second heat exchanger, wherein, a fan coil and a circulating water pump of the air conditioner are connected in series at the secondary end of the second heat exchanger for constituting a heating and refrigeration output loop of the air conditioner, the first heat exchanger is configured with a spray liquid type air heat exchange device, and the spray liquid type air heat exchange device mainly consists of a spray tank, an anti-freezing liquid storage tank, a clean water storage tank and a spray liquid circulating pump, which are connected in series at the primaryend of the first heat exchanger so as to constitute a spray liquid circulating loop. The novel air source heat pump air conditioner is characterized by high performance-price ratio and high energy efficiency ratio and can be applicable to being manufactured into a large-scale unit for being applied in a large-scale building as the air source heat pump air conditioner.

Owner:王全龄

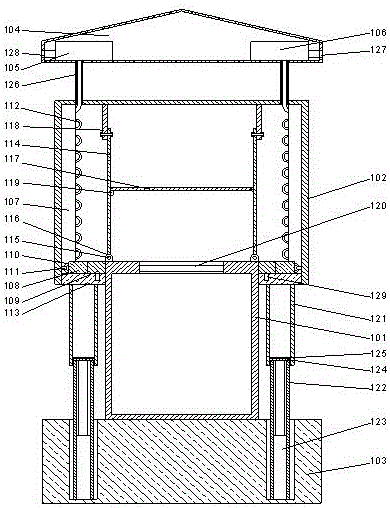

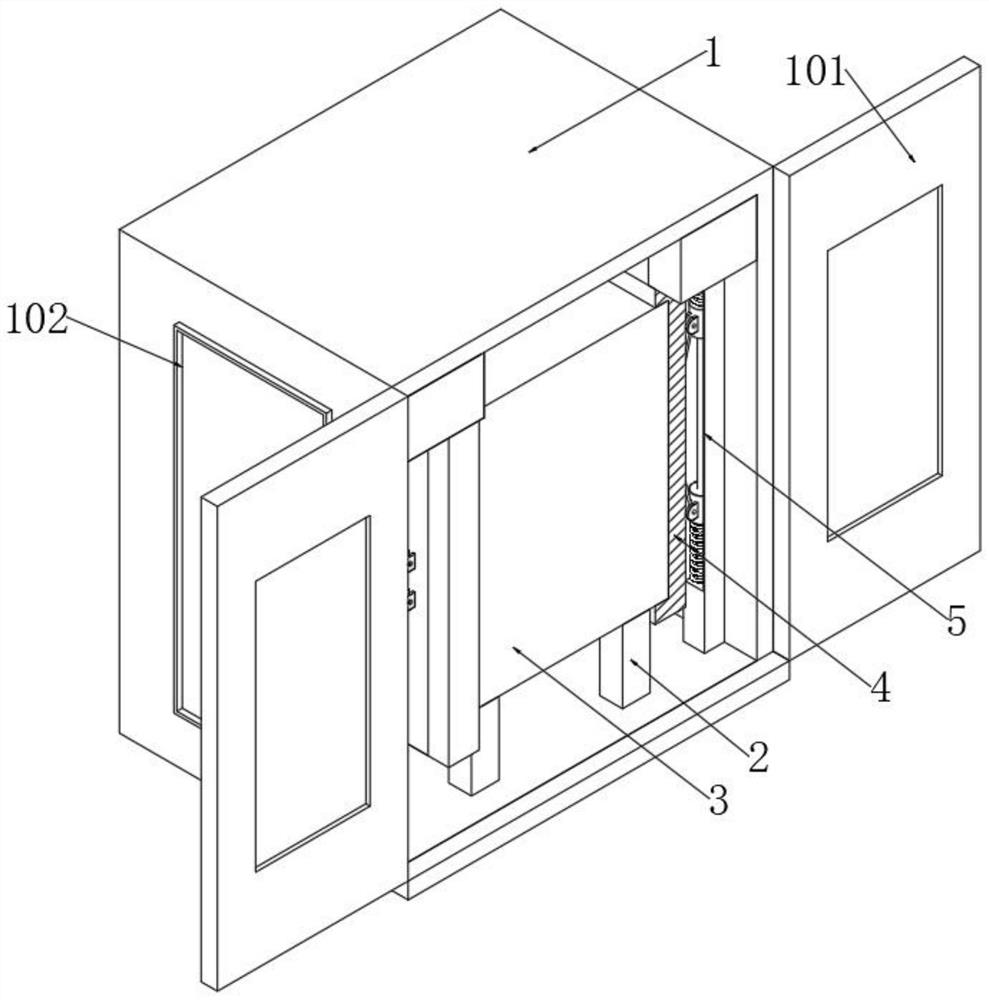

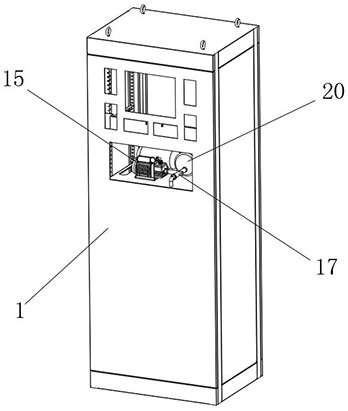

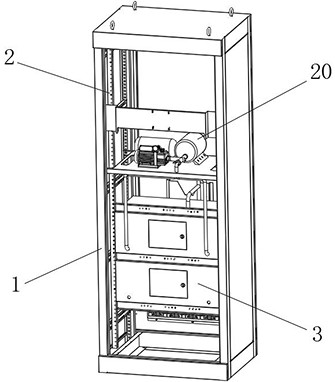

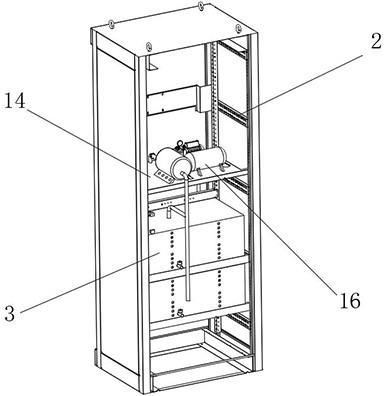

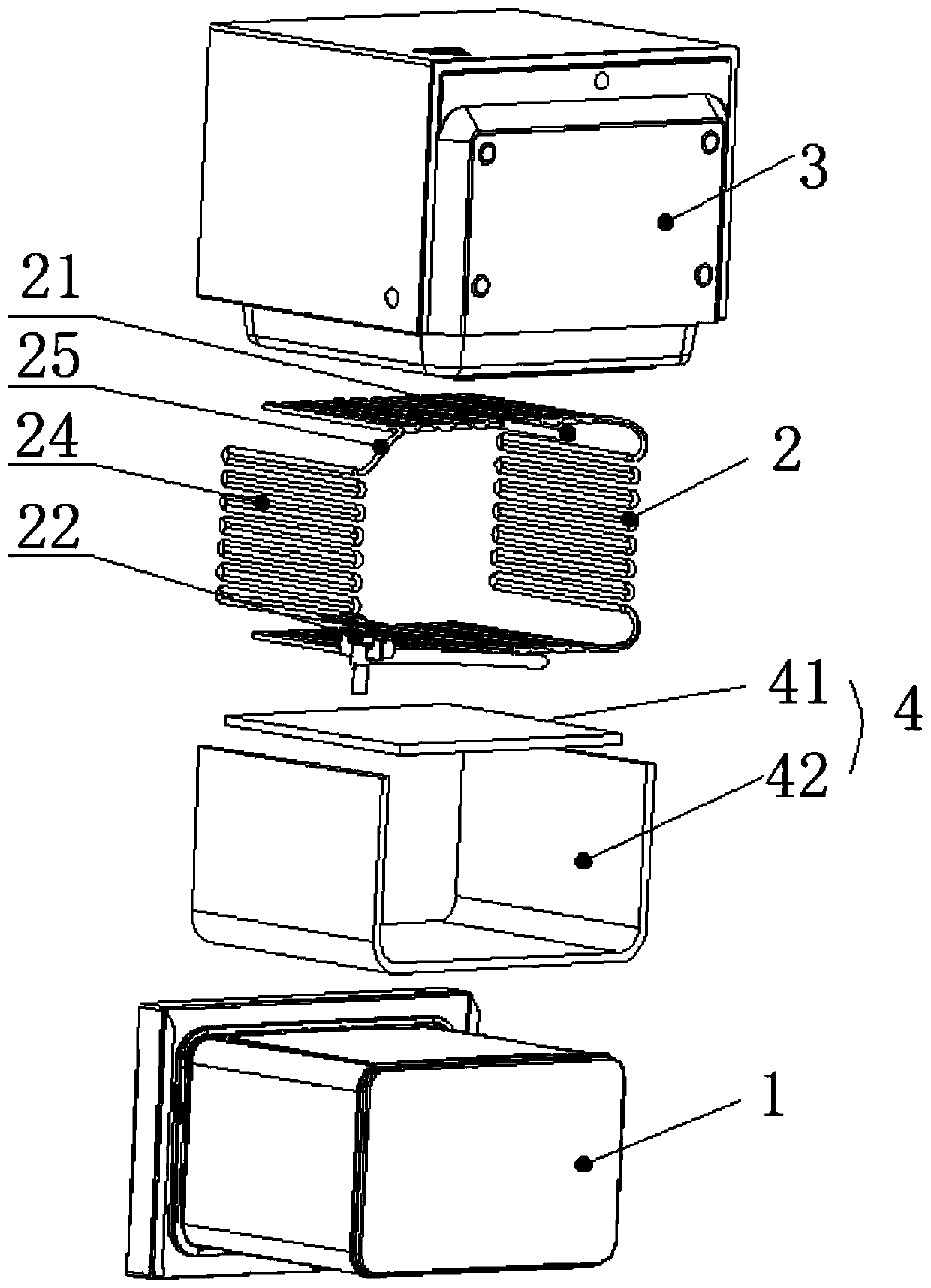

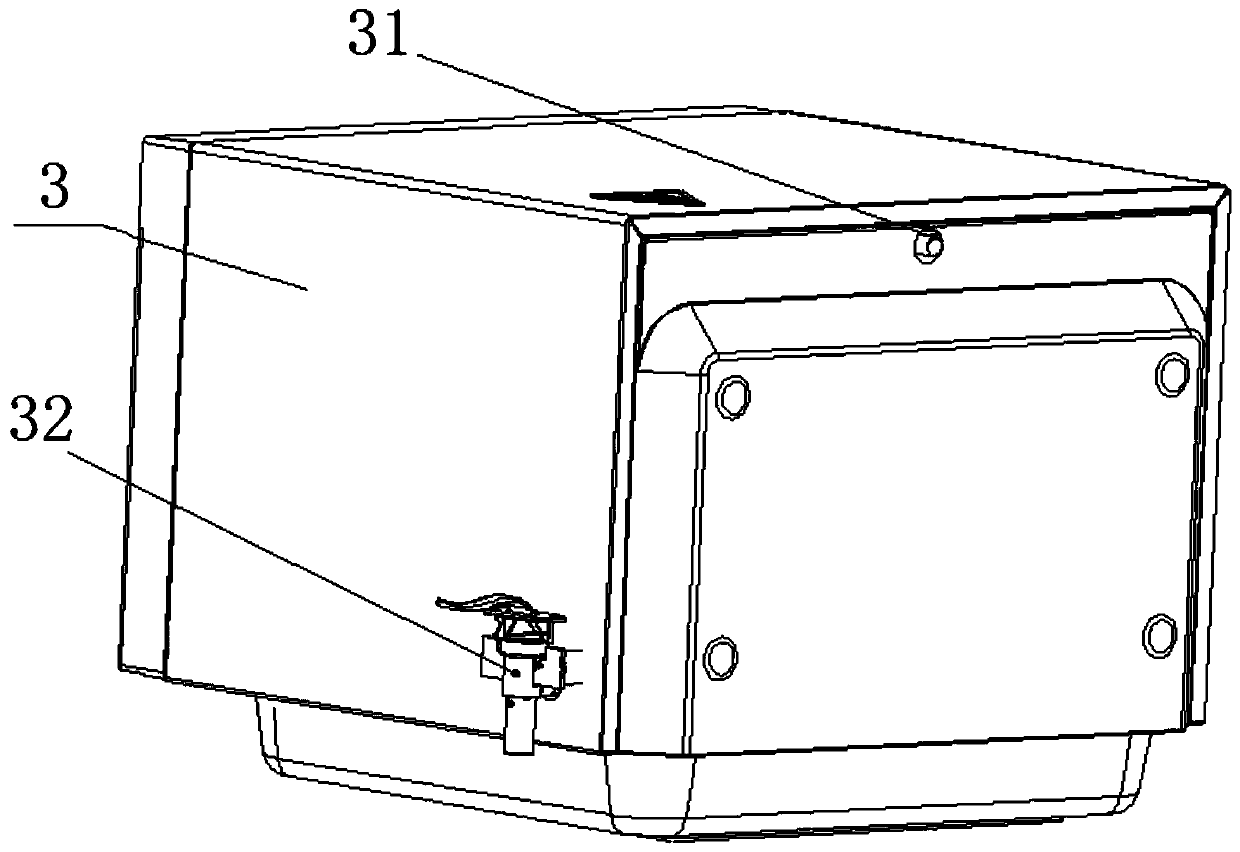

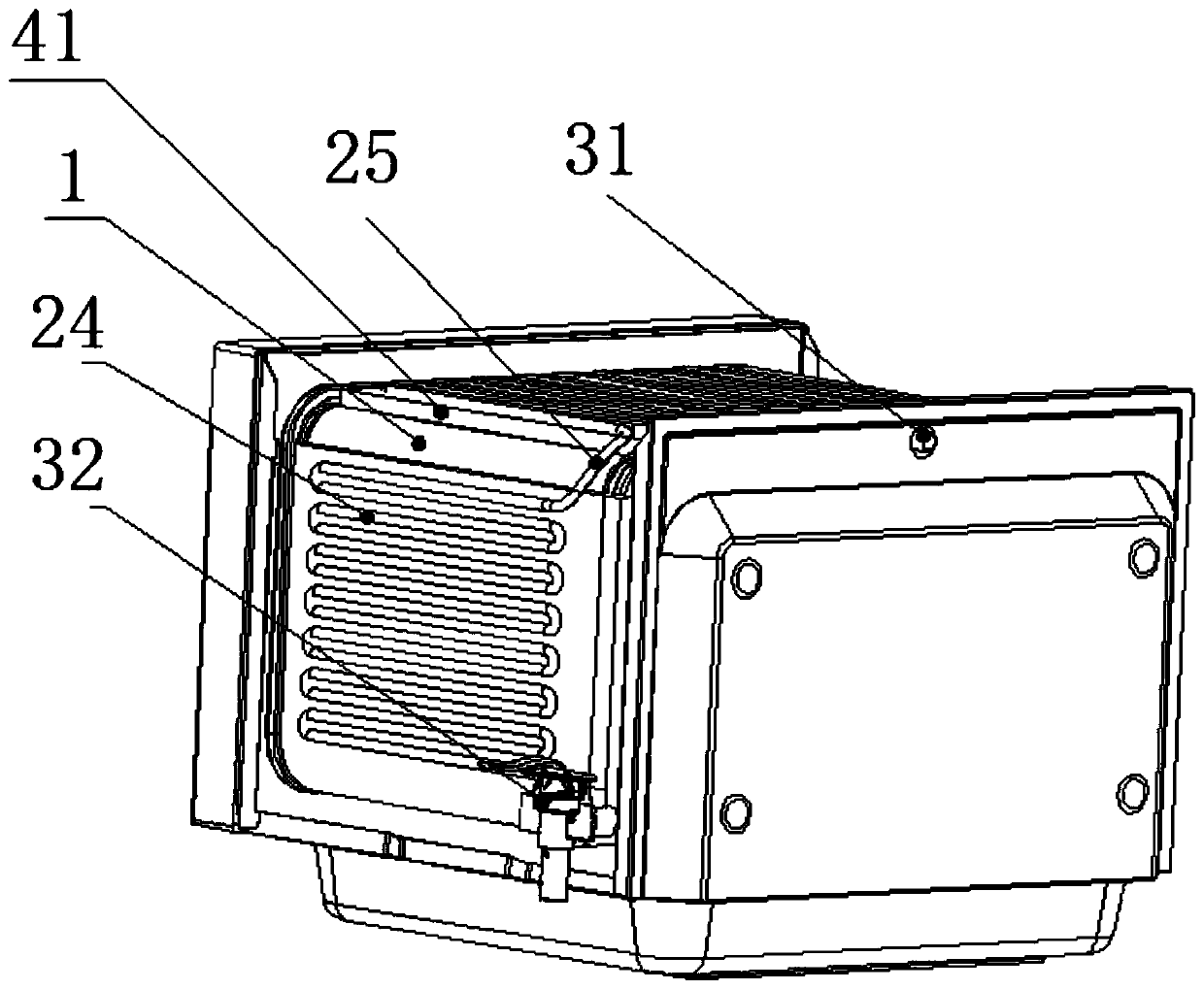

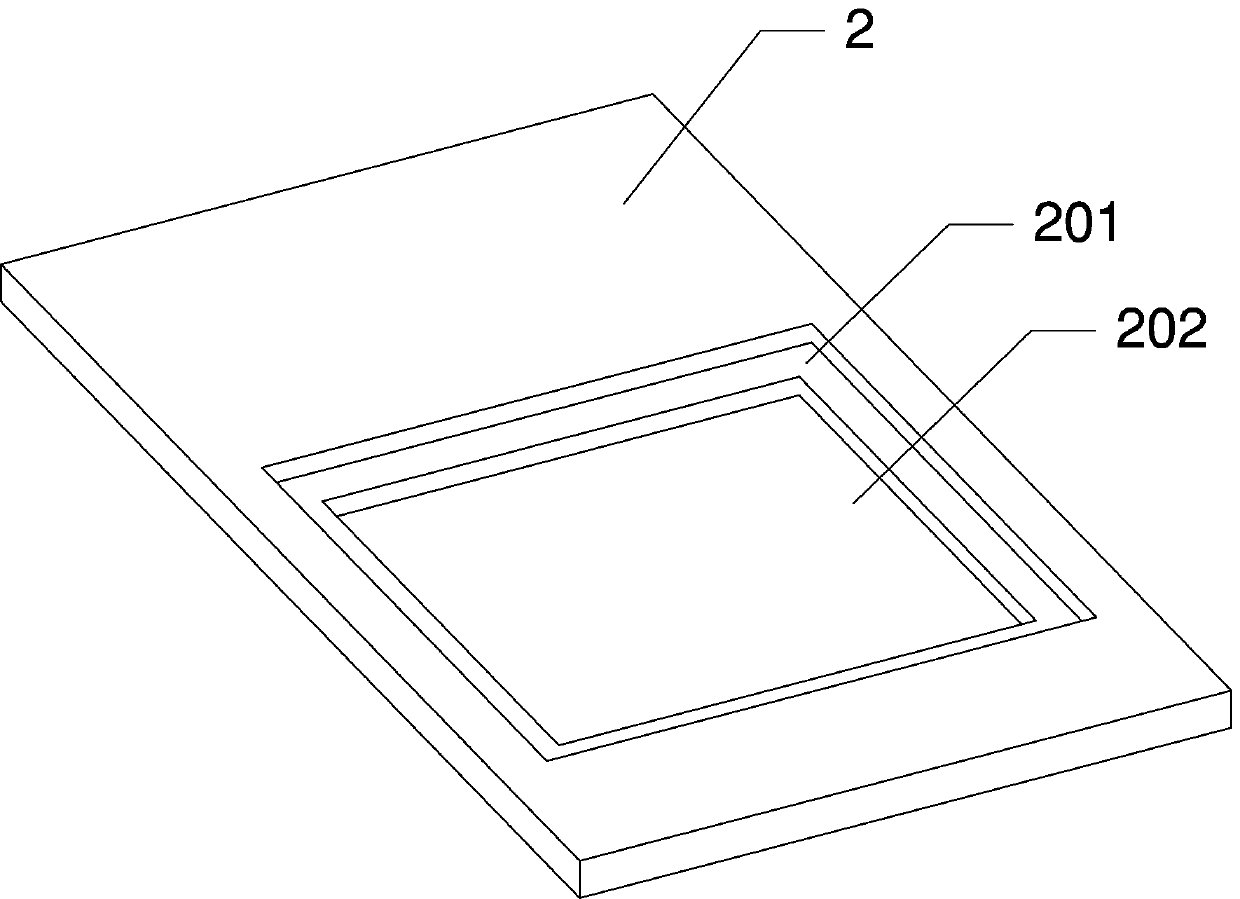

Switch cabinet with inner and outer cabinet bodies

InactiveCN105680353AIncrease electrical installation spaceLarge installation spaceSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsVentilation tubeEngineering

The invention discloses a switch cabinet with inner and outer cabinet bodies, which comprises an inner cabinet body and an outer cabinet body arranged outside the inner cabinet body, wherein both the inner cabinet body and the outer cabinet body are provided with cabinet doors; the top part of the outer cabinet body is provided with a top cover; the bottom part of the inner cabinet body is provided with a base; a cavity is formed between the outer wall of the inner cabinet body and the inner wall of the outer cabinet body; a vent pipe is arranged in the cavity; the vent pipe is clamped on the inner wall of the outer cabinet body via a buckle; the end surface of one side, facing the inner cabinet body, of the vent pipe is provided with a vent hole; and the lower end of the top cover is provide with a support. Ventilation is realized through adopting the vent pipe, the fact that the inner part of the cabinet body is likely to be affected with damp when a vent window structure is arranged is avoided, the cabinet body structure whose inner layer and the outer layer can be adjusted is adopted, the two layers of cabinet bodies can move relatively when needed, a structure with two vertical cabinet bodies is thus formed, and the space for mounting an electric appliance is increased.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +2

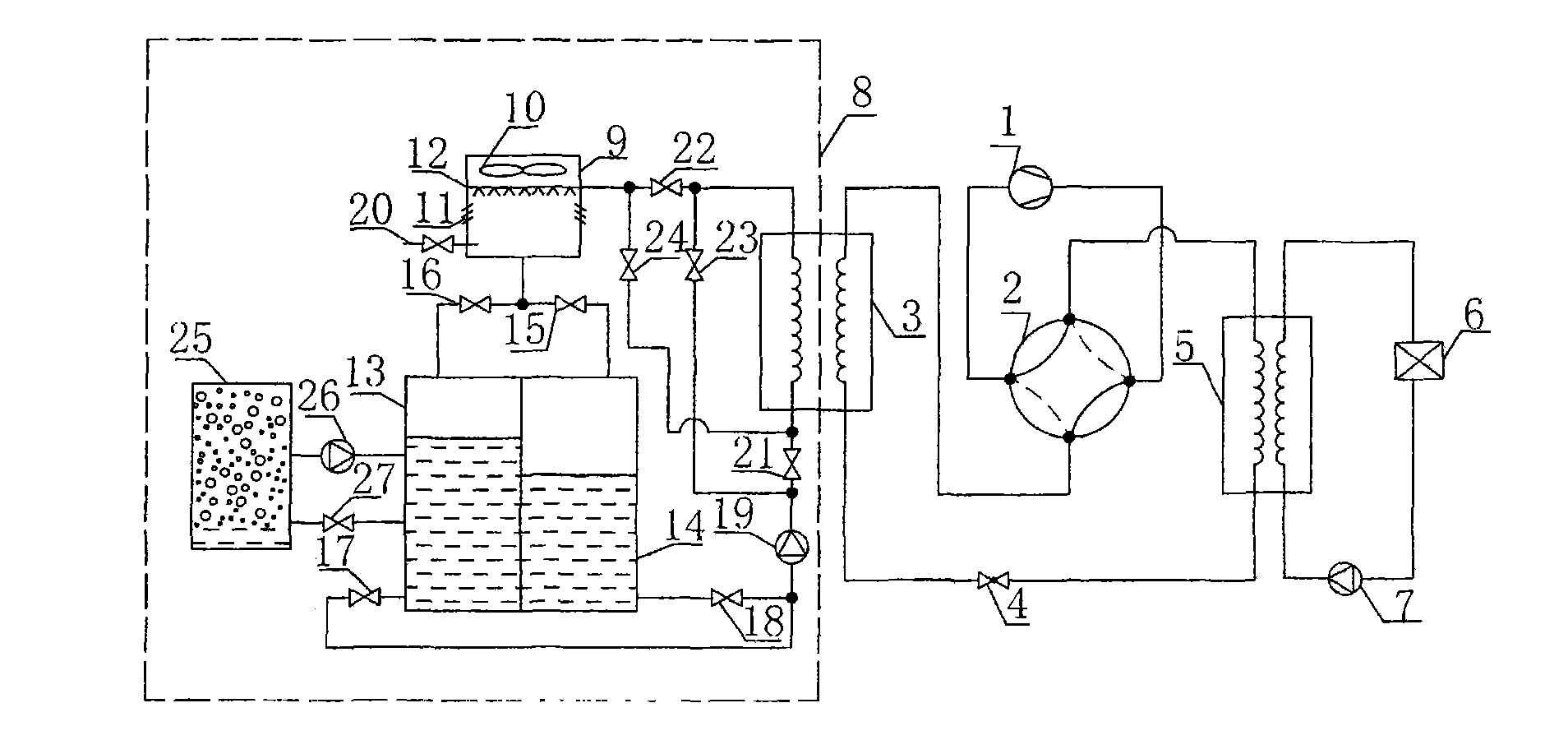

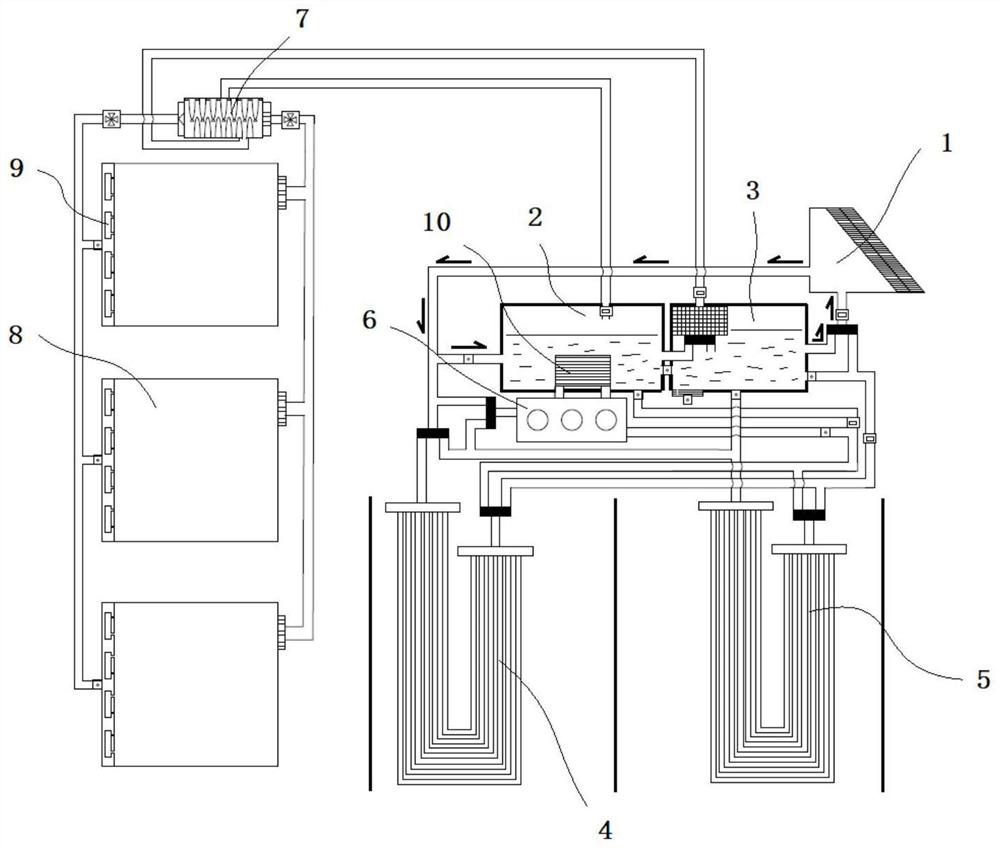

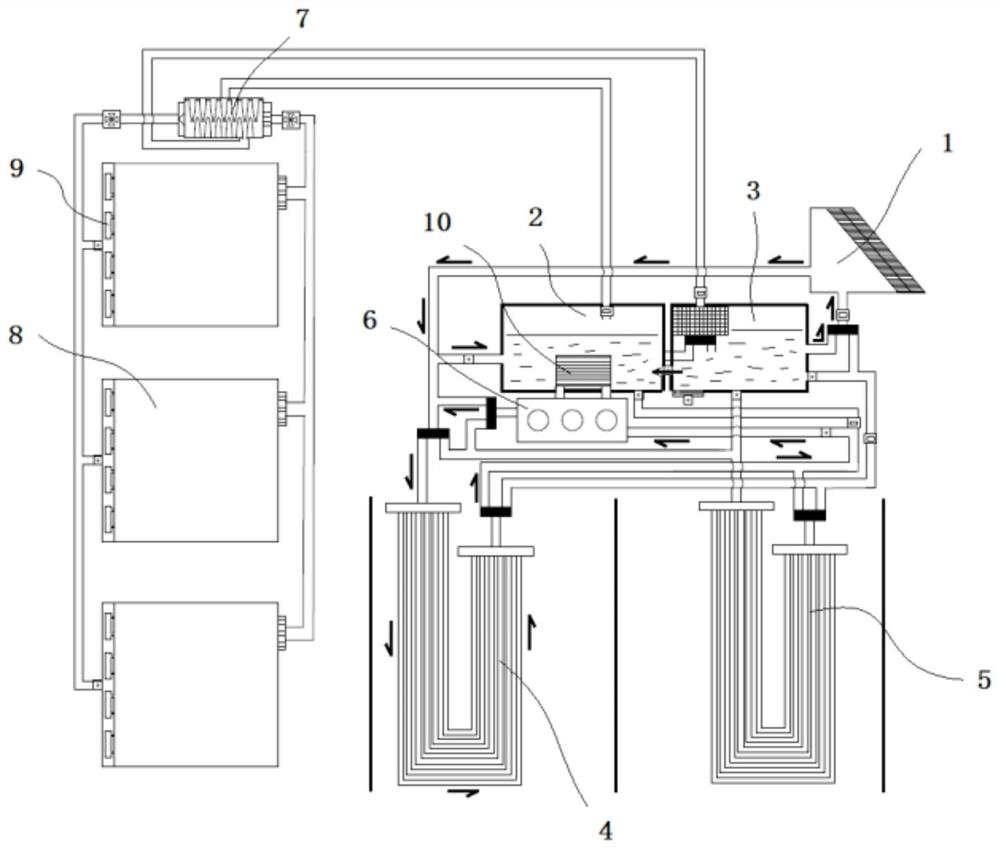

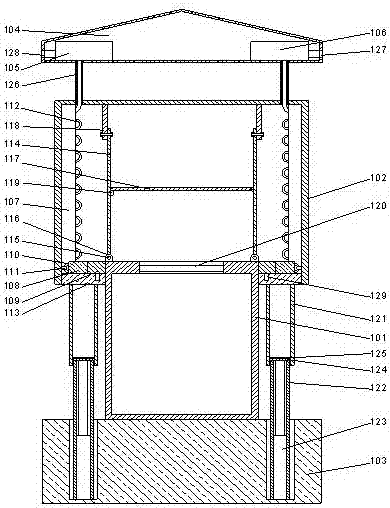

Solar energy and geothermal energy comprehensive utilization system with cross-seasonal cooling and heating adjusting function

ActiveCN113390194AStoring evenlyUniform supplyGeothermal energy generationGeothermal collectorsThermodynamicsEnergy absorption

The invention relates to a solar energy and geothermal energy comprehensive utilization system with a cross-seasonal cooling and heating adjustment function. The system comprises a solar energy collection end, an energy storage device, a cold energy absorption device, a buried pipe network, a ground source heat pump and an energy utilization end, wherein the solar energy collection end, the energy storage device and the cold energy absorption device are communicated to serve as an energy supplement pipeline; the solar energy collecting end is communicated with the heat storage buried pipe to serve as a first circulating pipeline; the cold energy absorption device and the cold storage buried pipe are communicated to serve as a second circulation pipeline; the heat storage buried pipe system and the ground source heat pump form a heat energy circulation pipeline, the cold storage buried pipe system and the ground source heat pump form a cold energy circulation pipeline, and the ground source heat pump is connected with the energy storage device; and the energy storage device, the energy use end and the cold energy absorption device are communicated to form a water circulation pipeline, and the energy use end is arranged in the energy utilization space. According to the system, energy is utilized in different seasons through a plurality of circulating pipelines, and cross-season storage and utilization of energy in summer and winter are achieved, thereby providing one-stop energy supply for a plurality of energy utilization spaces.

Owner:苏州正乙丙纳米环保科技有限公司

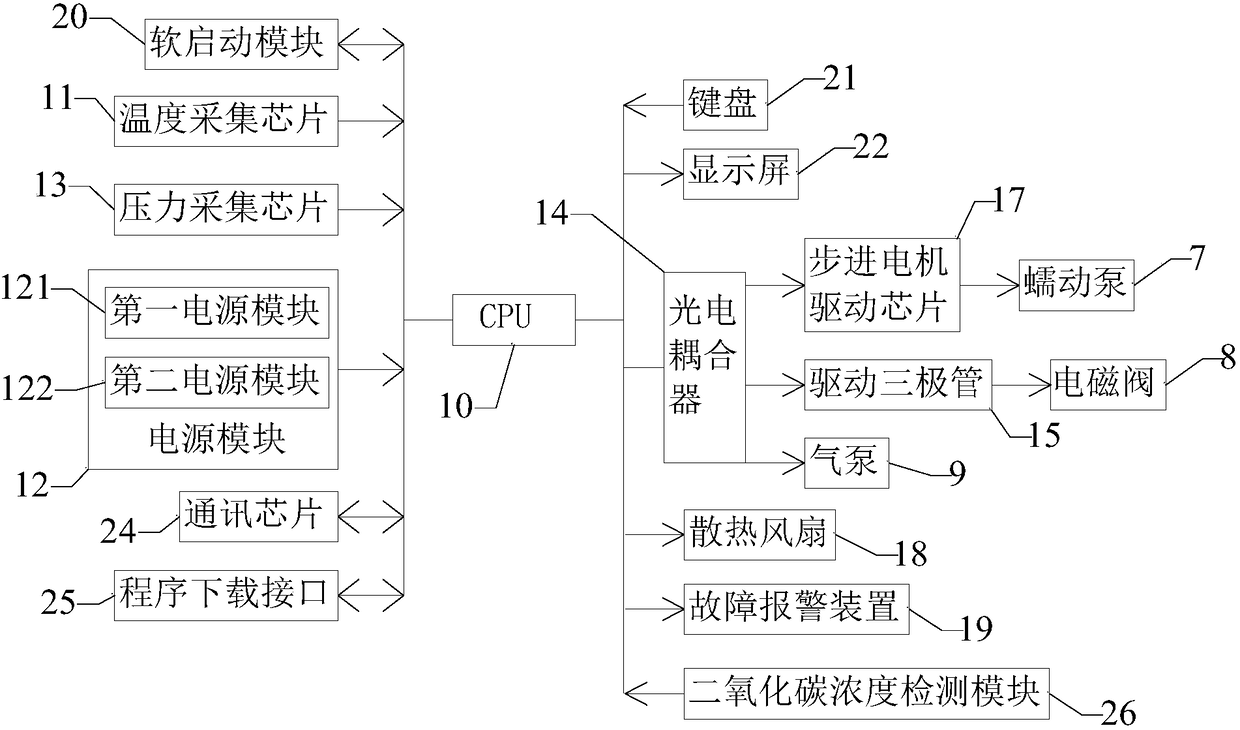

Full-automatic artificial airway management instrument

InactiveCN108096674AGuaranteed comfortAutomatic provisioningTracheal tubesBalloon catheterPeristaltic pumpSolenoid valve

The invention belongs to the technical field of medical instruments, and provides a full-automatic artificial airway management instrument. The full-automatic artificial airway management instrument comprises a box, wherein the box is provided with an operation panel, an artificial airway air bag interface, an air bag upper drainage tube, a normal saline supply tube and a gas feeding / discharging tube; solenoid valves are separately arranged on the artificial airway air bag interface, the air bag upper drainage tube, the normal saline supply tube and the gas feeding / discharging tube; peristaltic pumps are further separately arranged on the air bag upper drainage tube and the normal saline supply tube; an air pump is arranged on the gas feeding / discharging tube; the operation panel, the peristaltic pumps, the solenoid valves and the air pump are connected with a CPU arranged in the box; and the CPU is further connected with a power supply module and a pressure acquiring chip. The full-automatic artificial airway management instrument is skillful in design and simple and convenient to operate; and the technical problems that in the prior art, when an artificial airway is used, the working intensity is large, and the operation accuracy is poor are solved.

Owner:北京中安维华科技有限公司

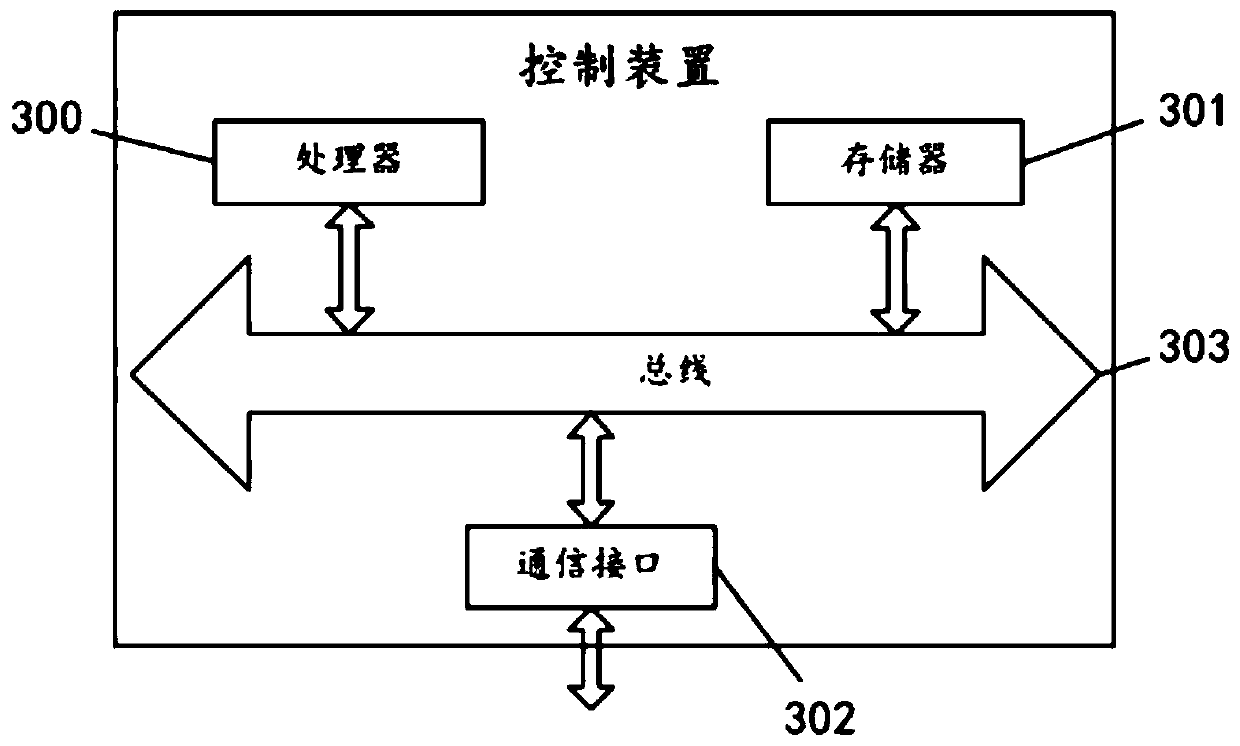

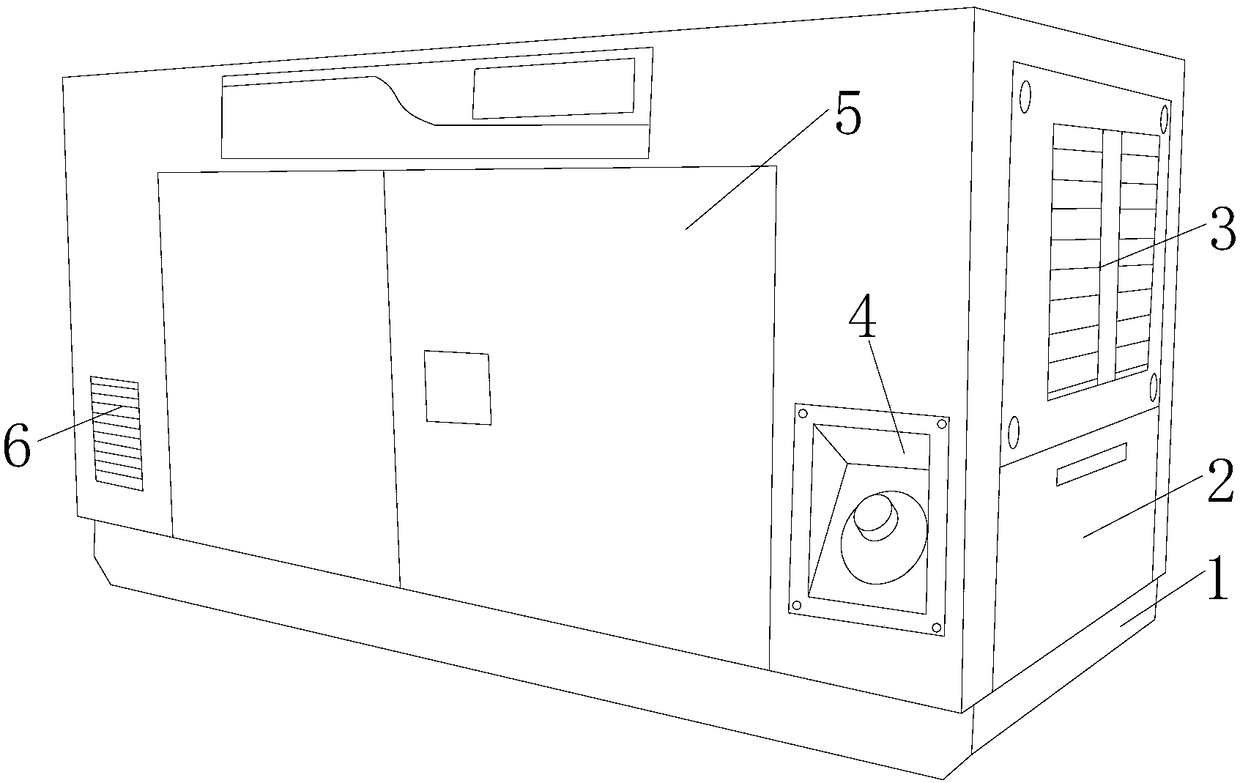

Optimization control system based on comprehensive energy model and control method thereof

PendingCN114364213AAvoid downtimeRealize cooling operationDispersed particle filtrationTransportation and packagingReciprocating motionEngineering

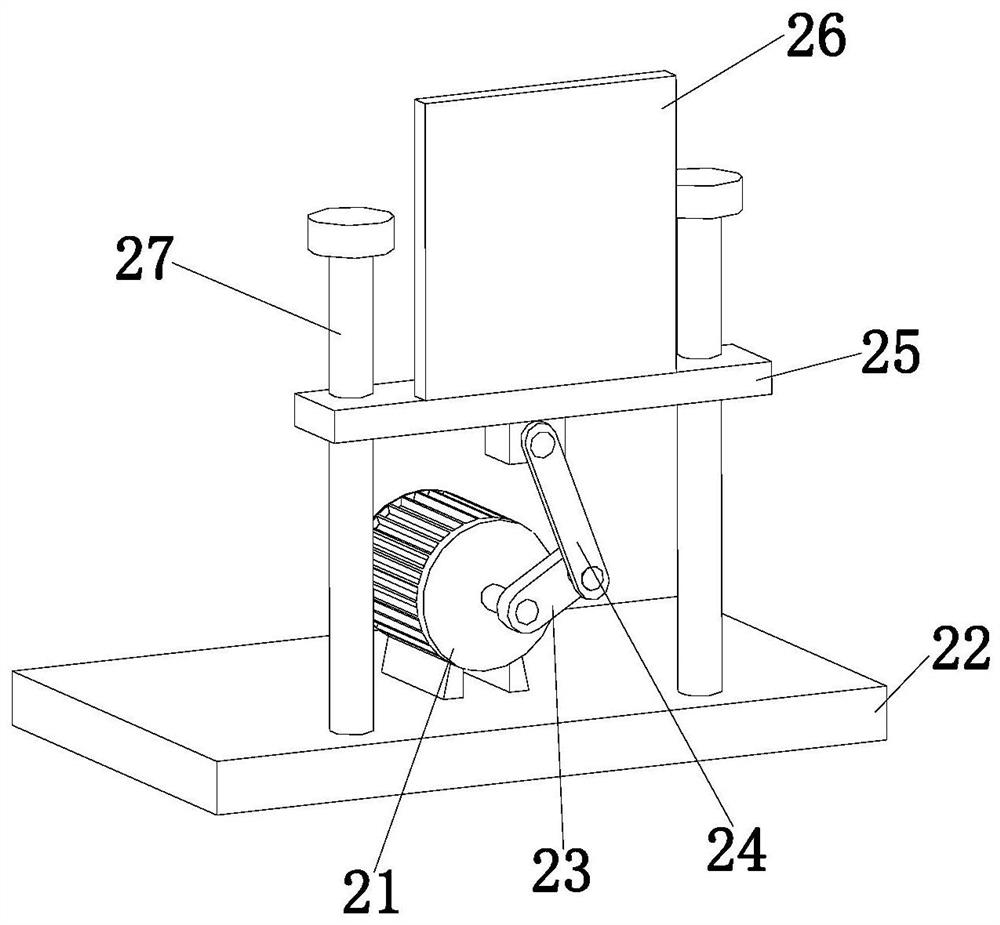

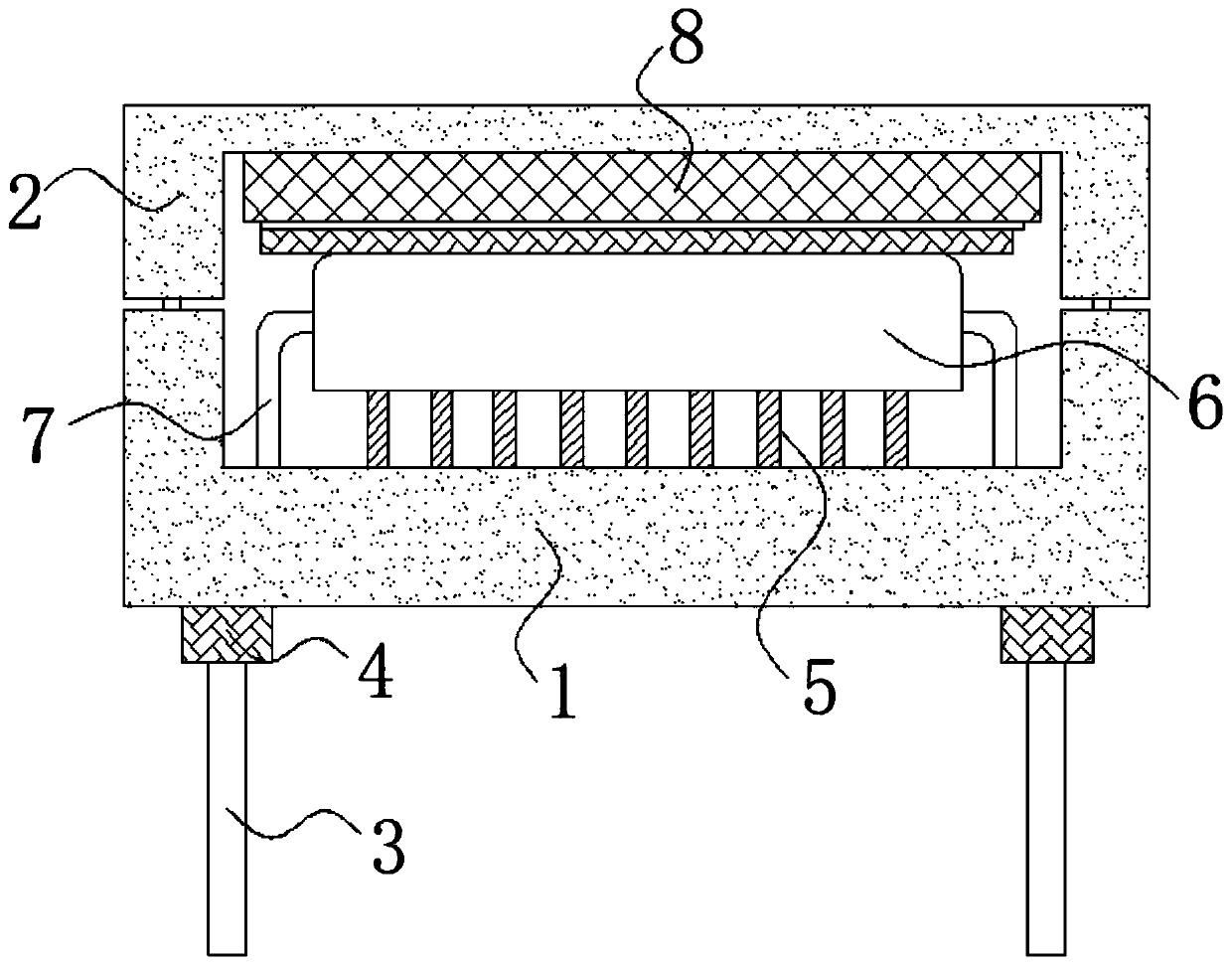

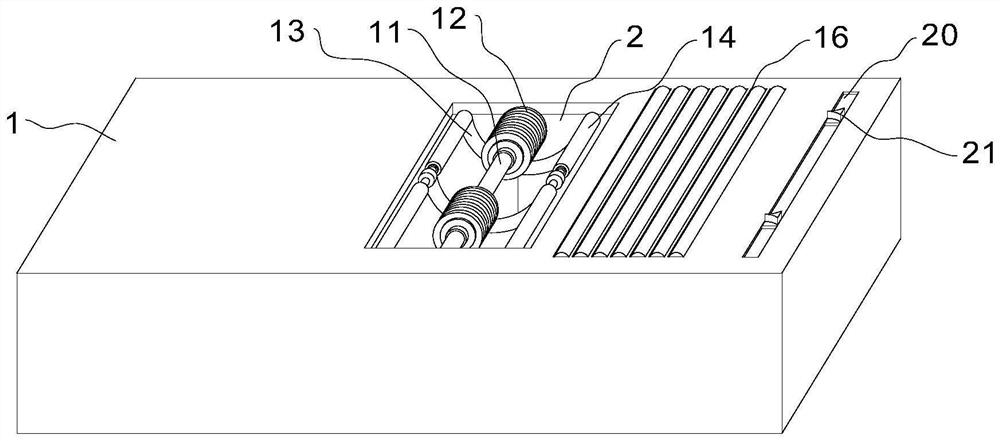

The invention discloses an optimal control system based on a comprehensive energy model and a control method thereof.The optimal control system comprises a box body, a control device body is arranged in the box body, supporting legs are fixedly connected in the box body, the control device body is arranged above the supporting legs, clamping plates are arranged on the two sides of the control device body, and the clamping plates are arranged on the two sides of the control device body. A clamping plate is arranged on the side wall of the box body, a mounting mechanism is arranged at the outer side end of the clamping plate, stabilizing assemblies are arranged at the upper end and the lower end of the clamping plate, a shell is arranged on the side wall of the box body, a heat dissipation mechanism is arranged on the shell, and a cleaning mechanism is arranged in the shell. The invention relates to the technical field of control devices. According to the optimal control system based on the comprehensive energy model and the control method of the optimal control system, automatic wiping and cleaning of the dustproof net plate are achieved through the arranged cleaning mechanism, reciprocating motion of the brush roller can be achieved through the arranged cleaning mechanism, dust cleaning of the dustproof net plate on the side wall of the movable frame is achieved, and the situation that an air inlet is blocked by external dust is avoided.

Owner:ZHEJIANG ZHONGXIN POWER ENG CONSTR CO LTD +1

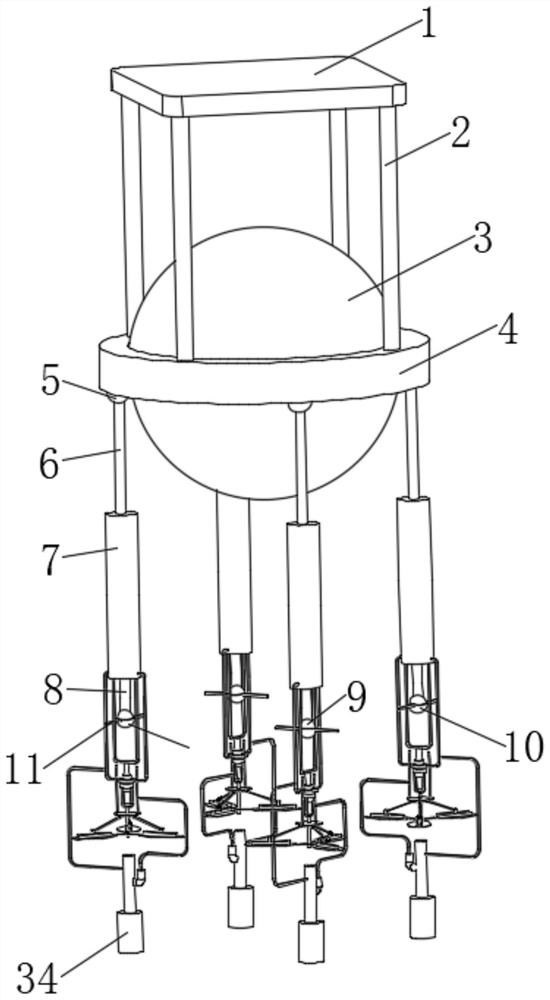

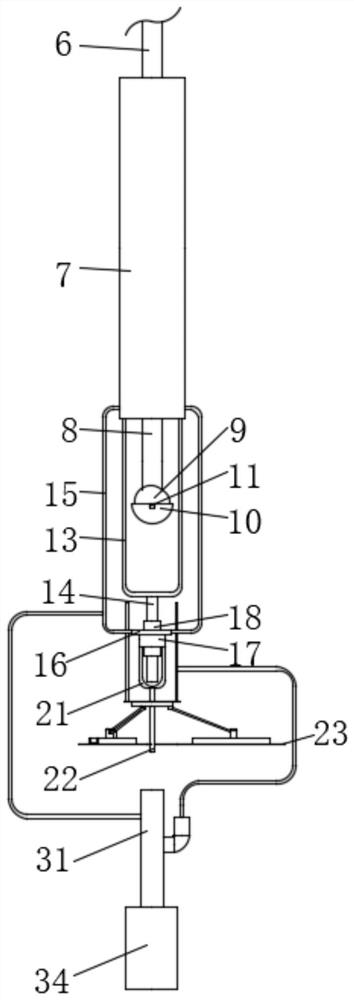

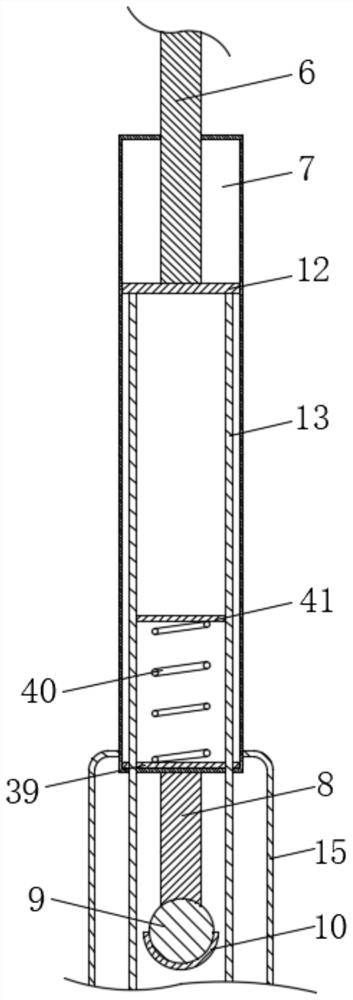

Assembled high-rise building frame with good anti-seismic effect and assembling method

ActiveCN113718979AAchieve supportIncrease temperatureHuman health protectionProtective buildings/sheltersArchitectural engineeringTuned mass damper

The invention discloses an assembled high-rise building frame with a good anti-seismic effect and an assembling method. The assembled high-rise building frame comprises a top plate fixed to the roof of a high-rise building, the lower surface of the top plate is fixedly connected with four steel cables, the bottoms of the four steel cables are fixedly connected with a swing ball, and the arc-shaped contour of the swing ball is fixedly connected with a connecting ring; a first universal ball is rotationally connected to the lower surface of the connecting ring in a limiting mode, a telescopic rod is fixedly connected to the bottom of the first universal ball, a sleeve is slidably connected to the telescopic rod, a traction shaft is fixedly connected to the bottom of the sleeve, and a second universal ball is fixedly connected to the bottom of the traction shaft. According to the assembled high-rise building frame with the good anti-seismic effect and the assembling method, through cooperative use of the structures, the problems that in the actual use process, due to the fact that a traditional high-rise building frame is difficult to be well matched with a tuned mass damper, the matching effect of the tuned mass damper and the traditional high-rise building frame is single, and the better anti-seismic effect is difficult to achieve are solved.

Owner:广东华域重工有限公司

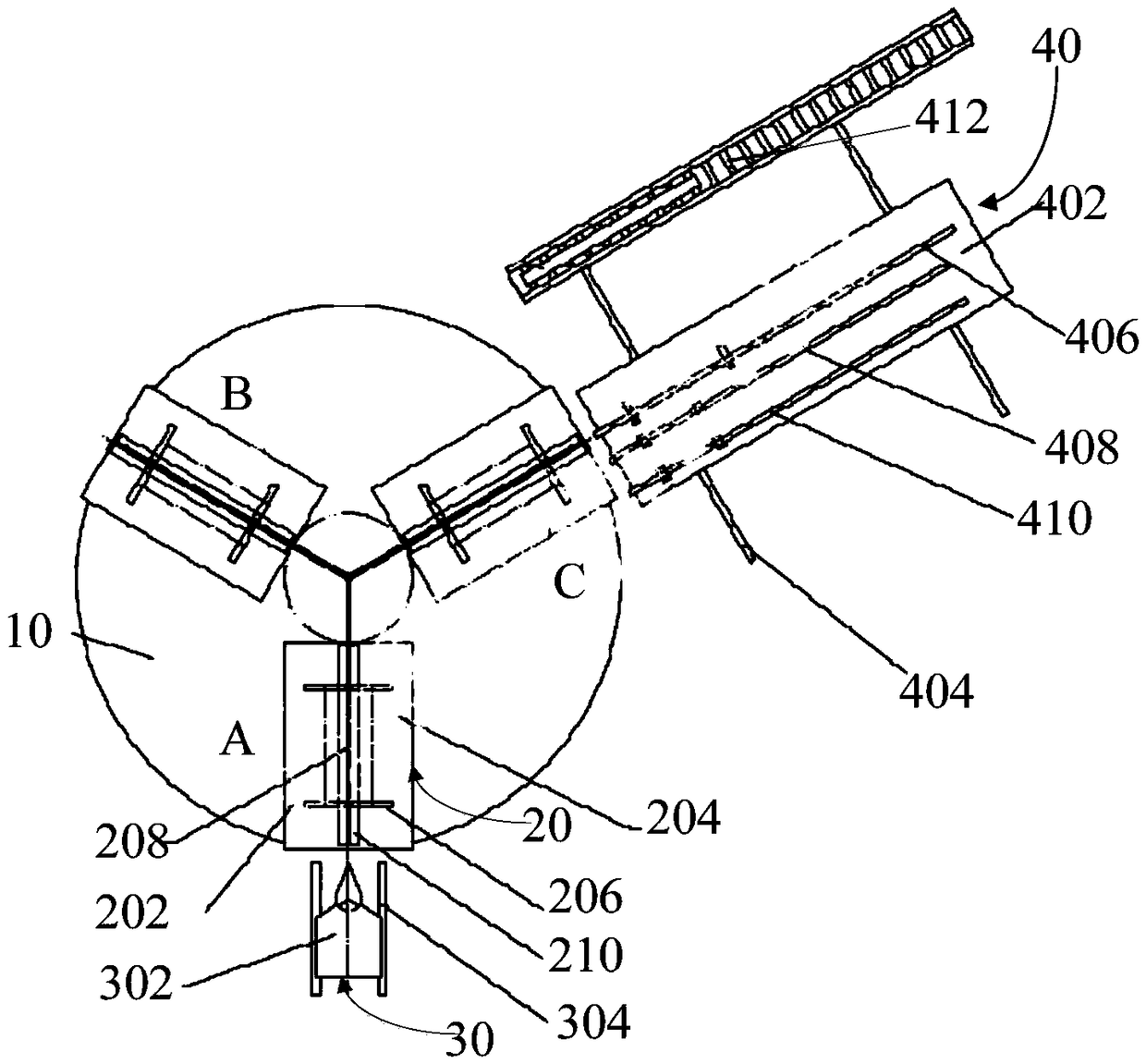

Centrifugal casting equipment

The invention provides centrifugal casting equipment. The centrifugal casting equipment comprises a rotary disc, a plurality of centrifugal casting machines, an automatic pouring trolley and a translation trolley, wherein the plurality of centrifugal casting machines are uniformly arranged on the rotary disc, and rotate to corresponding station positions along with the rotation of the rotary disc,and the station positions comprise an automatic pouring station, an automatic cooling casting station and an automatic die drawing-cleaning-spraying station; the automatic pouring trolley is arrangedin a manner of being cooperated with the centrifugal casting machines on the automatic pouring station; and the translation trolley is arranged in a manner of being cooperated with the centrifugal casting machines on the automatic die drawing-cleaning-spraying station. Through the technical scheme of the invention, continuous automatic pouring working, automatic cooling casting working and automatic die drawing-cleaning-spraying working are realized, realization for a continuous centrifugal casting process for different types of casting dies is benefited, and realization for the continuity and high efficiency of centrifugal casting is benefited, so that the production efficiency of centrifugal casting is greatly increased.

Owner:BINZHOU YATAI ART POWER PARTS

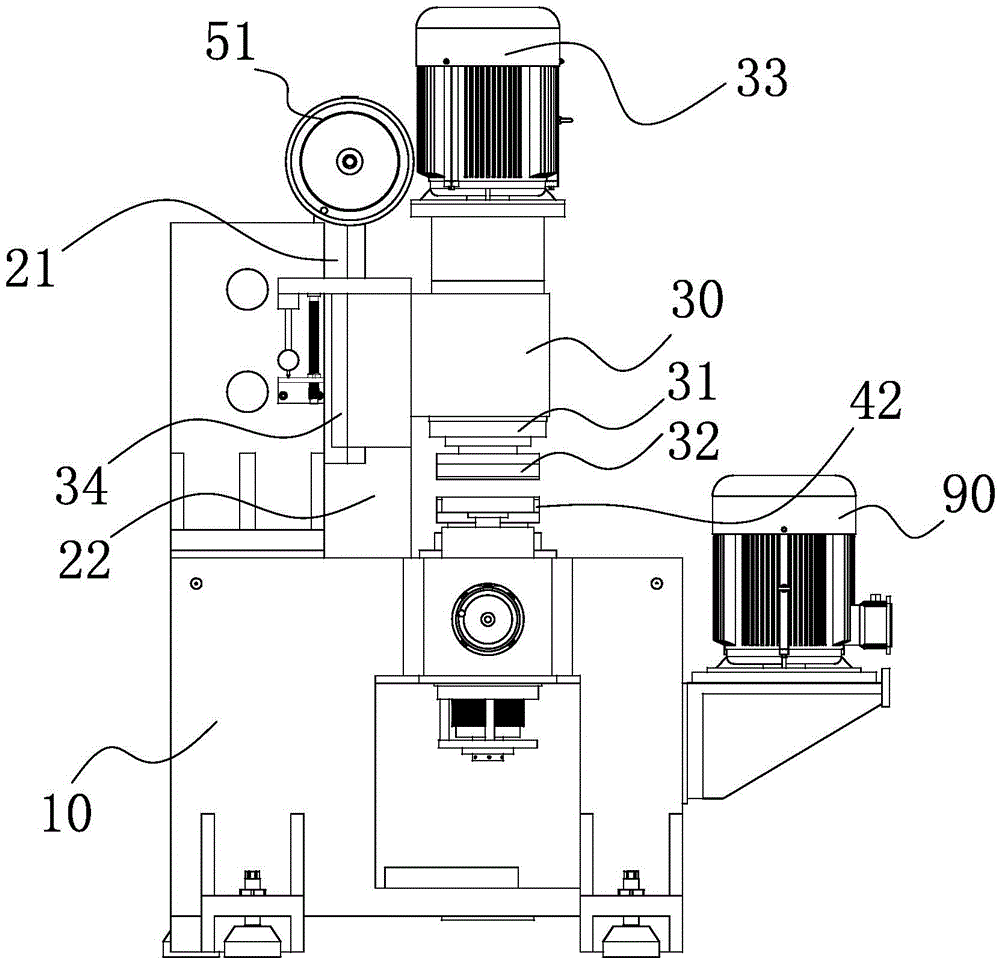

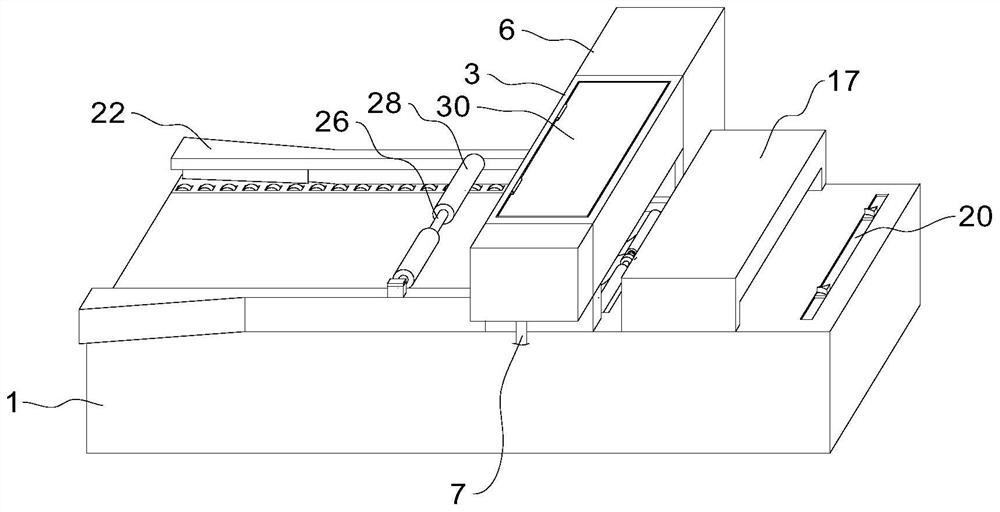

Cooling system of vertical end surface grinding machine

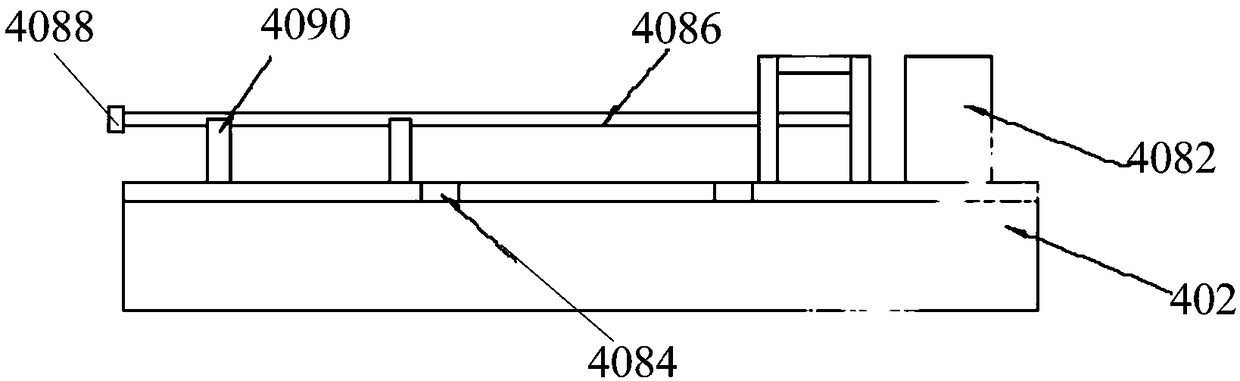

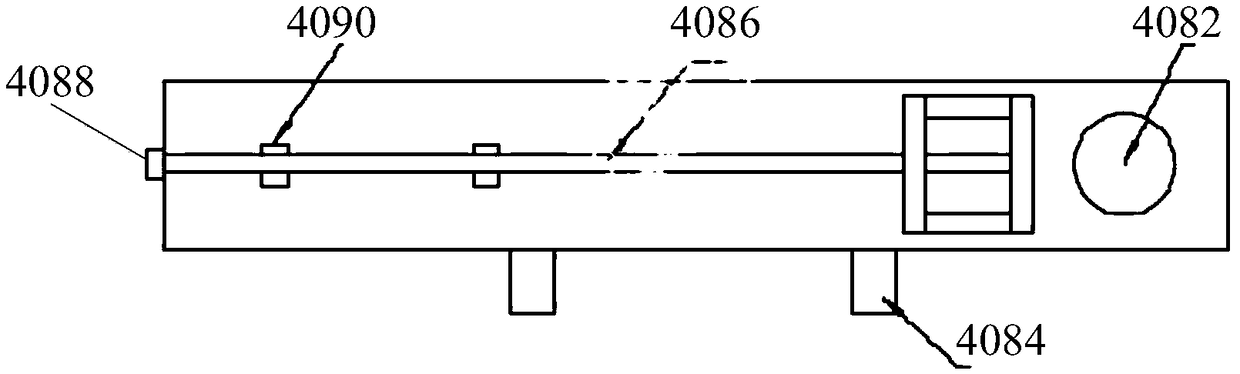

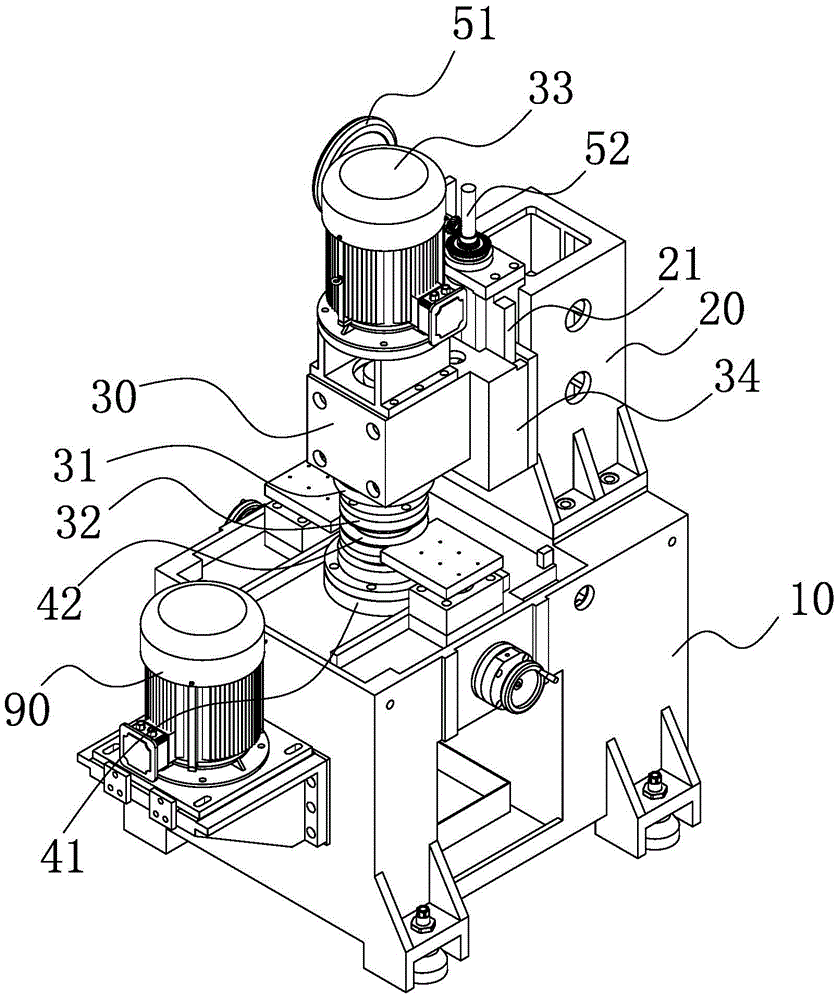

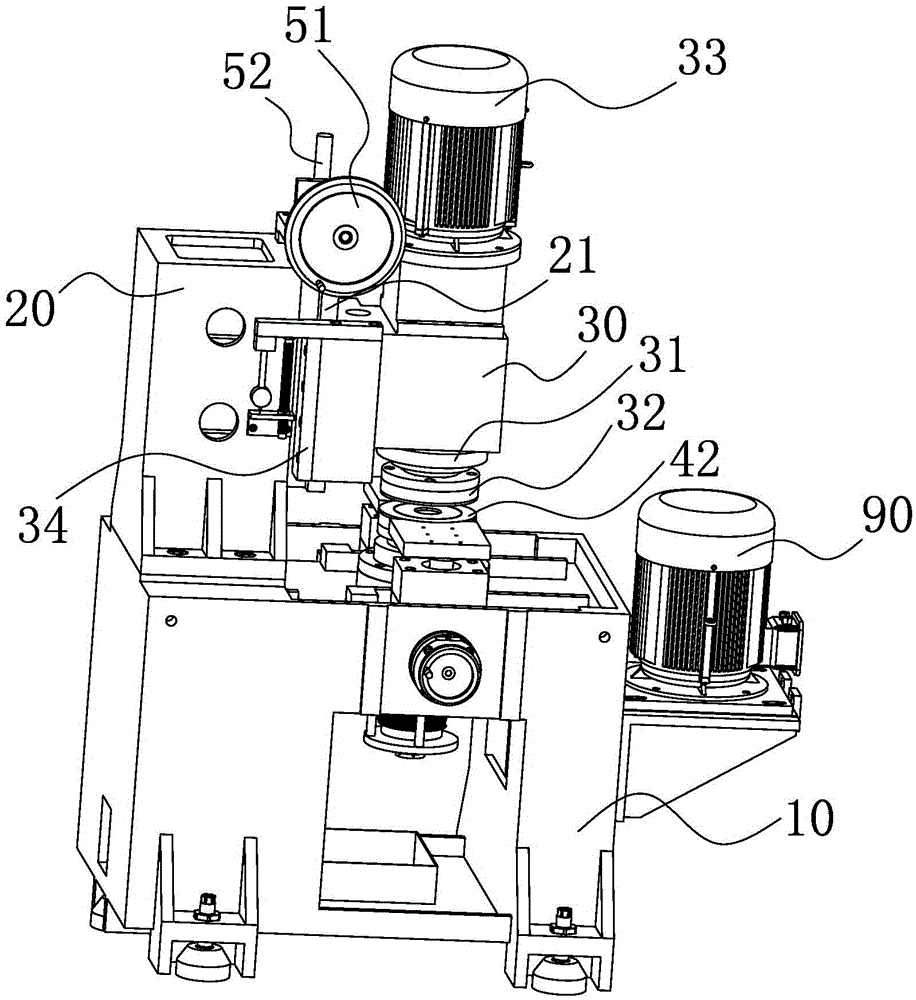

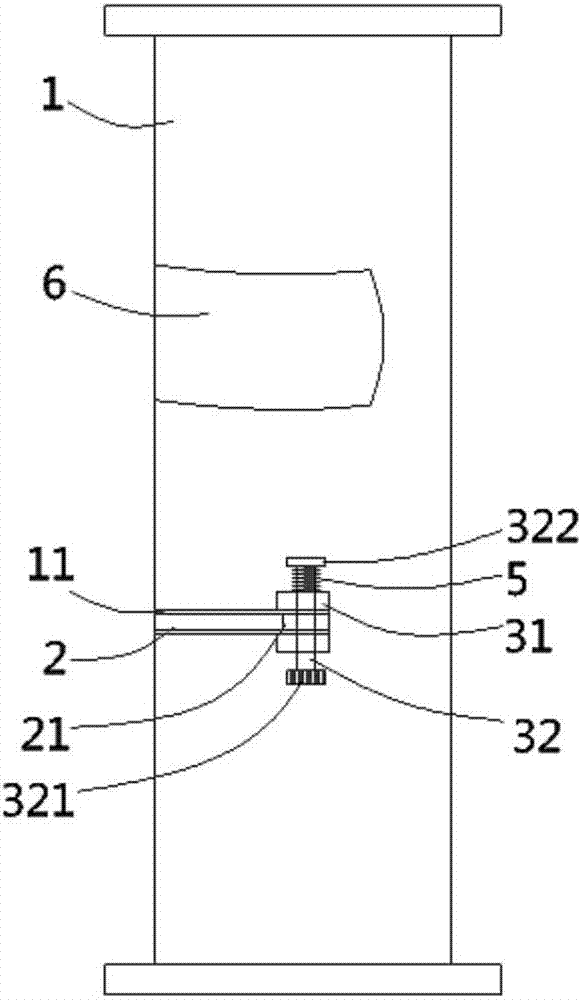

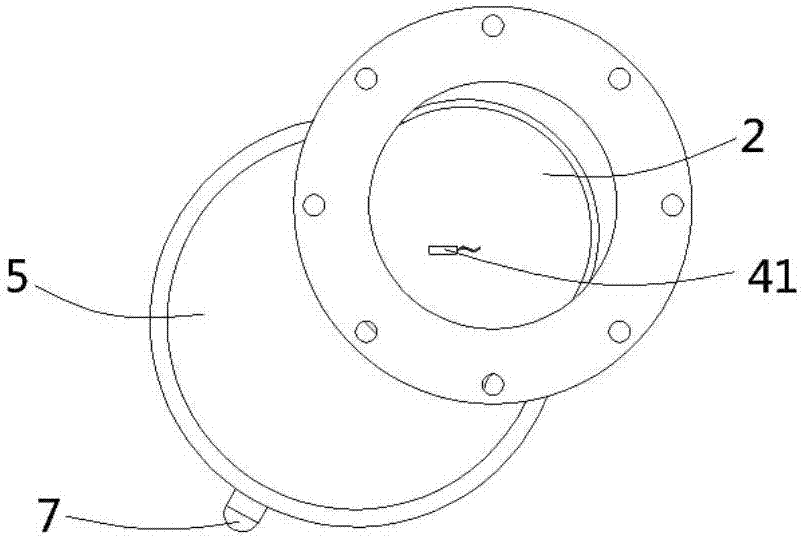

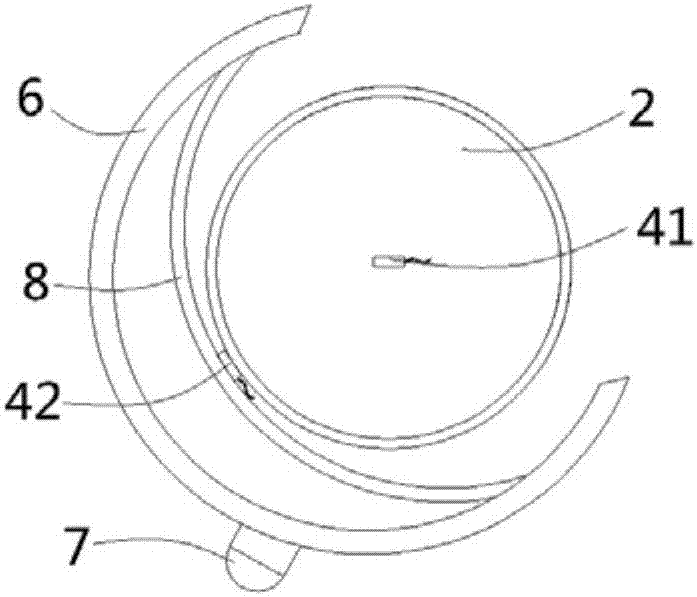

PendingCN105479342AReasonable structural designRealize cooling operationGrinding carriagesGrinding drivesCooling effectEngineering

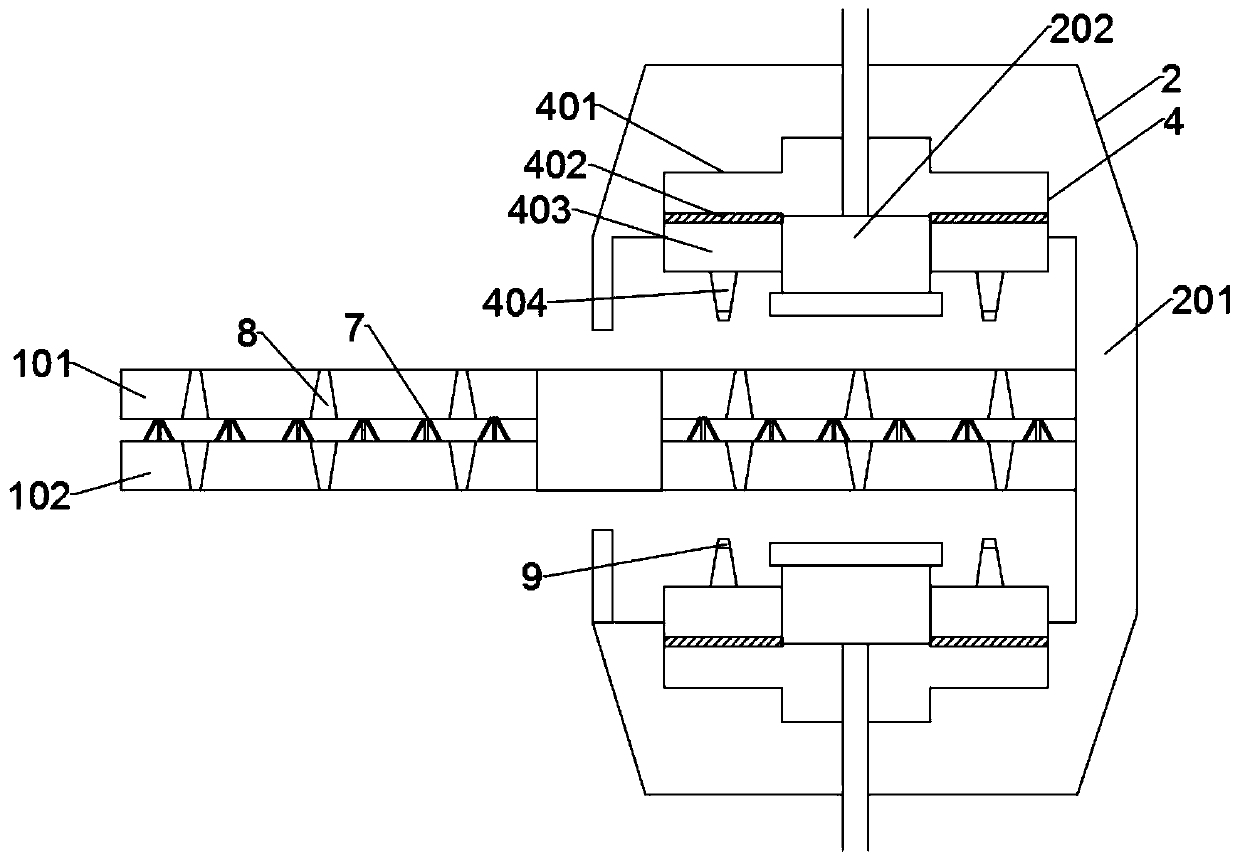

The invention provides a cooling system of a vertical end surface grinding machine, and belongs to the technical field of processing machine tools. The cooling system of the vertical end surface grinding machine comprises: a frame serving as a mounting basal body and provided with a machining channel; a stand column fixedly mounted on the frame and positioned on one side of the machining channel; a main shaft box movably mounted on the frontal surface of the stand column and positioned rightly above the machining channel, wherein an upper main shaft is mounted below the main shaft box, an upper grinding wheel for molding the upper end surface of a molded product is mounted on the upper main shaft, the main shaft box can vertically and linearly slip with the upper grinding wheel on the stand column, a center channel for conveying grinding liquid is formed in the middle part of the upper main shaft, and the grinding liquid sent out from the center channel is uniformly dispersed to the outer periphery of an upper grinding wheel; and a water tank detachably mounted on the frame and used for accommodating the grinding liquid, recovering the grinding liquid finishing a cooling operation and sending the grinding liquid into the center channel so as to realize recycling of the grinding liquid. The cooling system of the vertical end surface grinding machine has the advantages of ideal cooling effect and reliable work.

Owner:NINGBO GREAT MACHINE TOOL

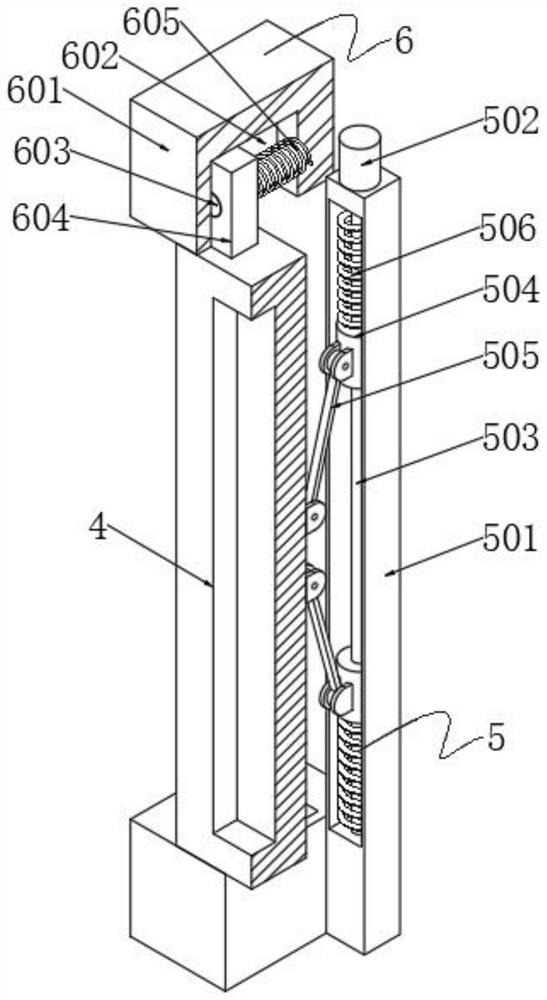

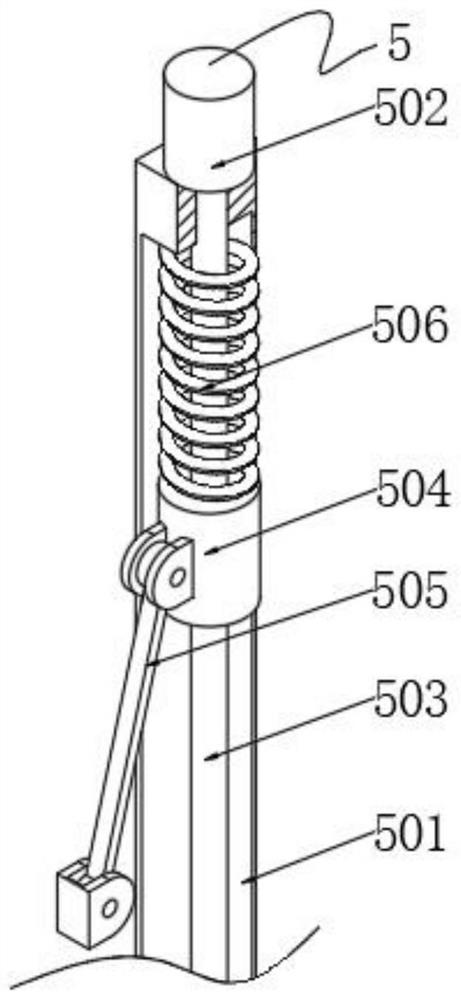

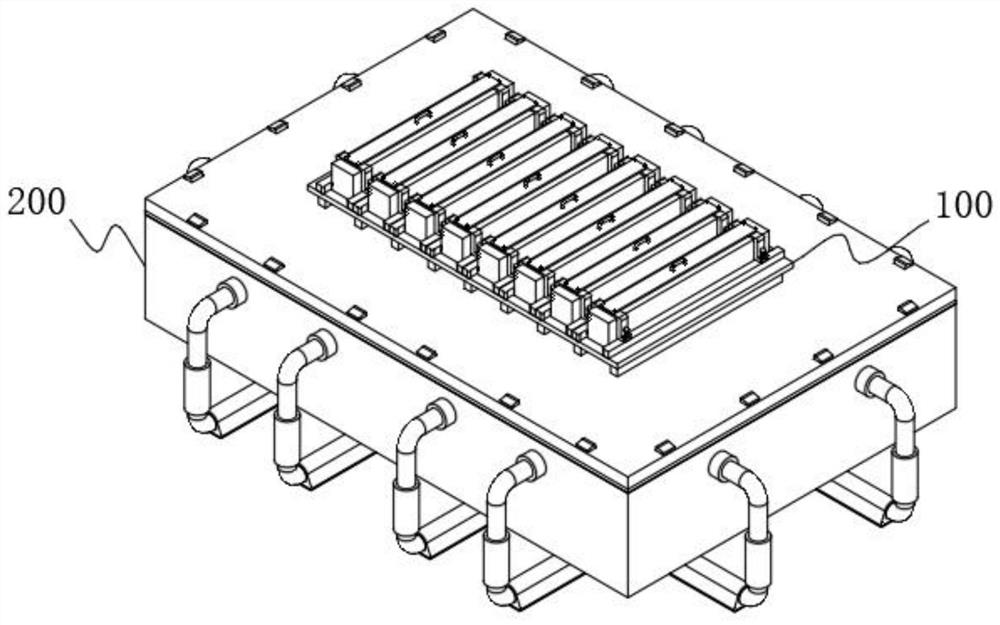

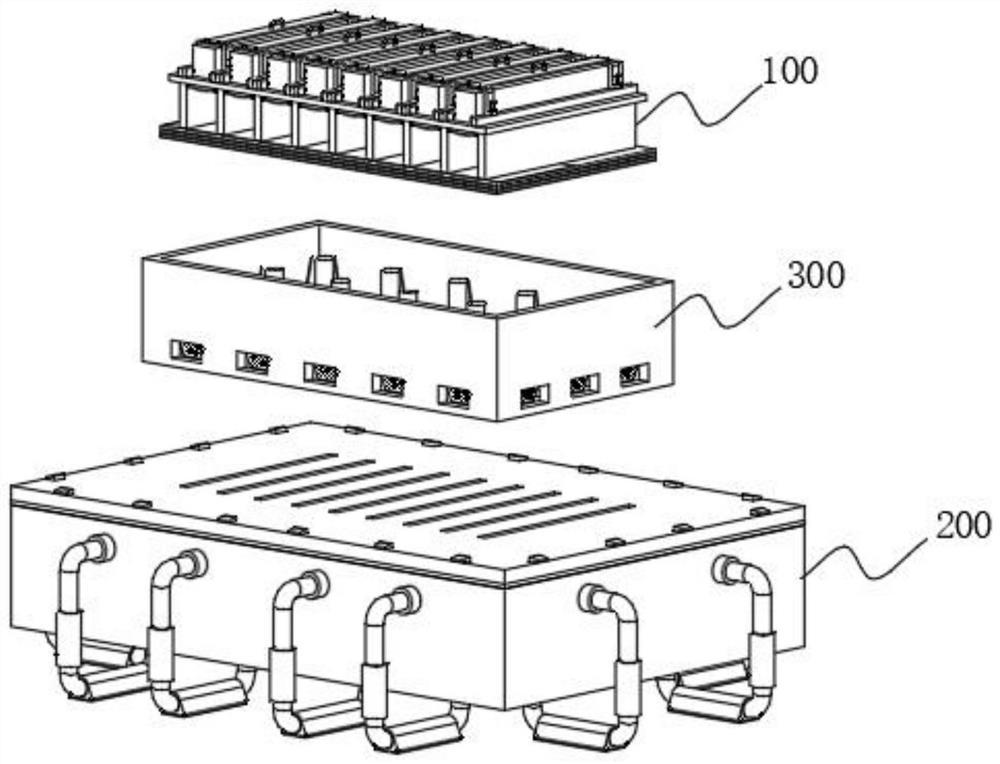

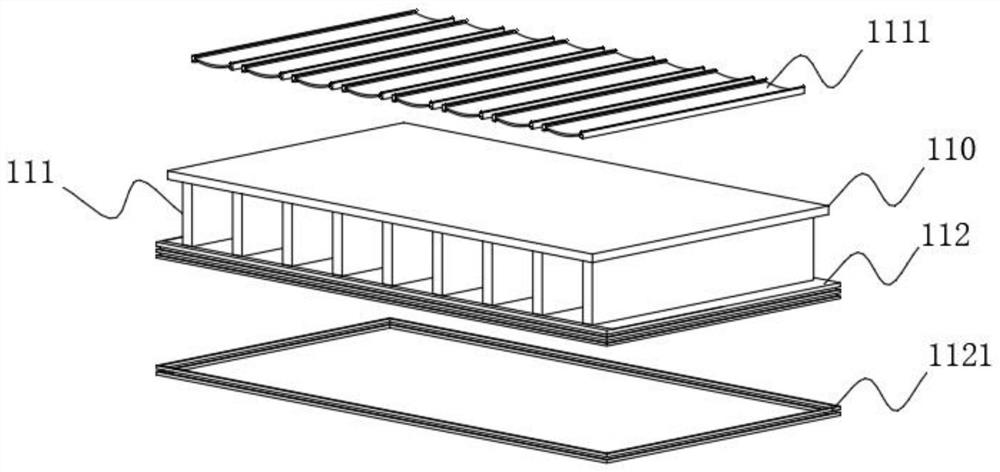

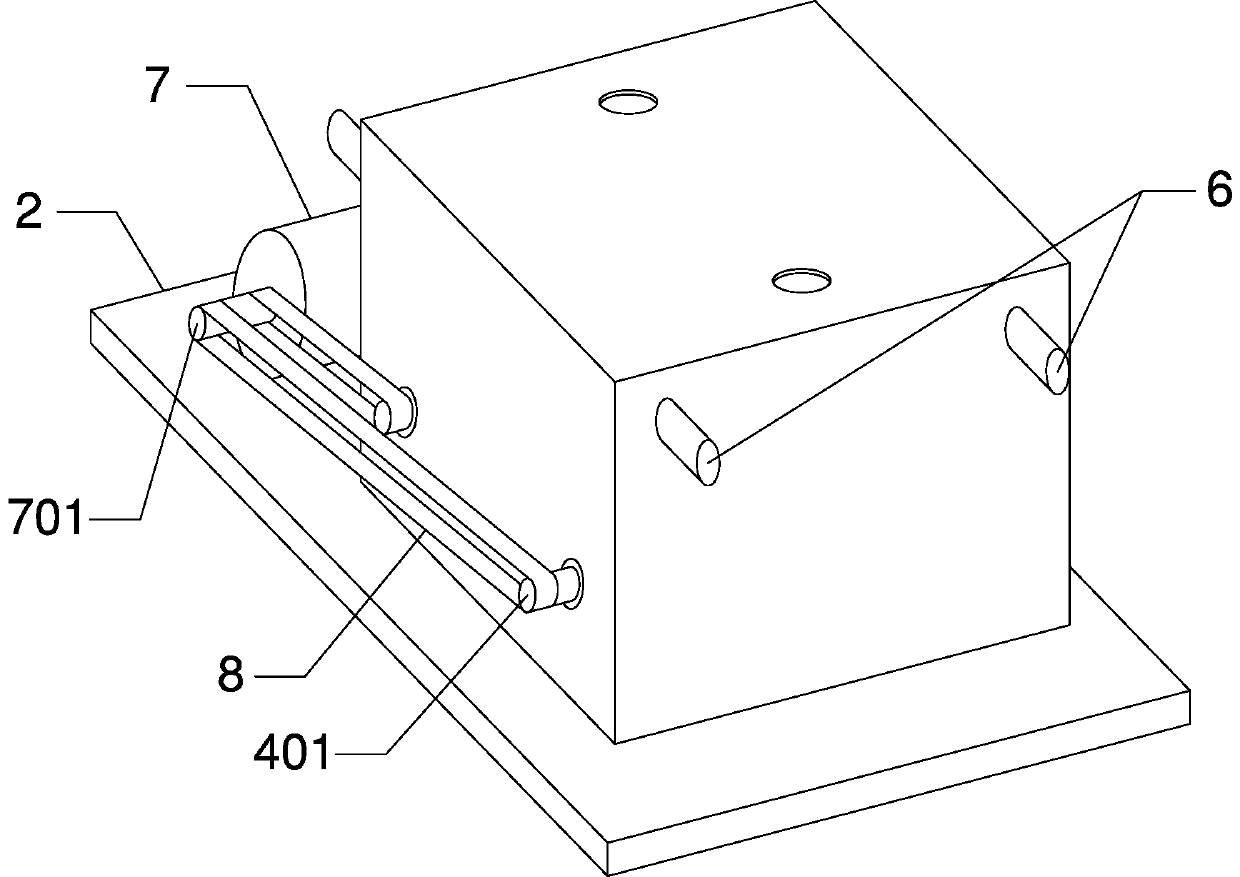

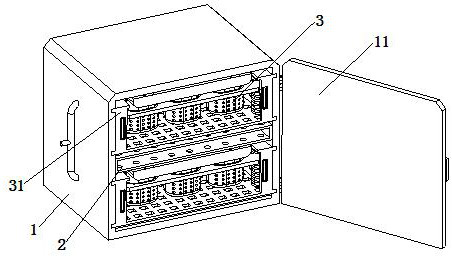

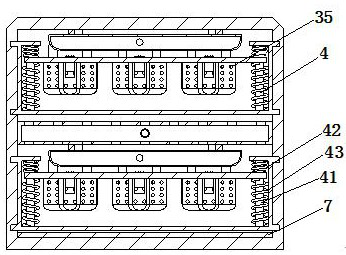

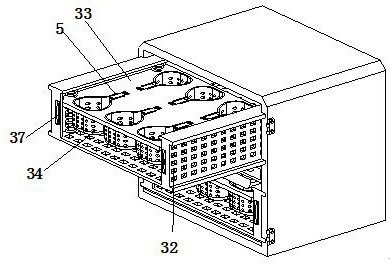

Mounting rack capable of carrying fluorine ion battery and use method of mounting rack

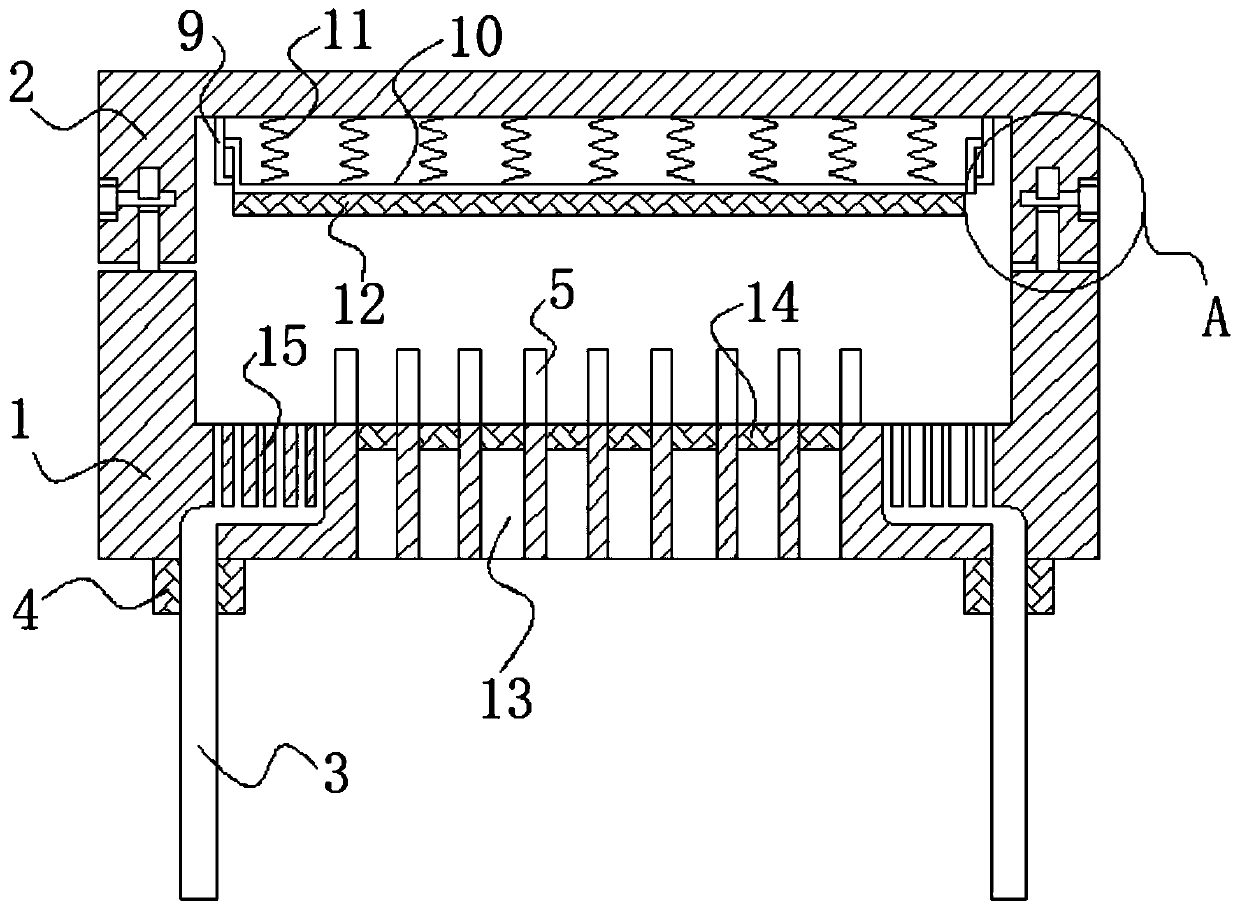

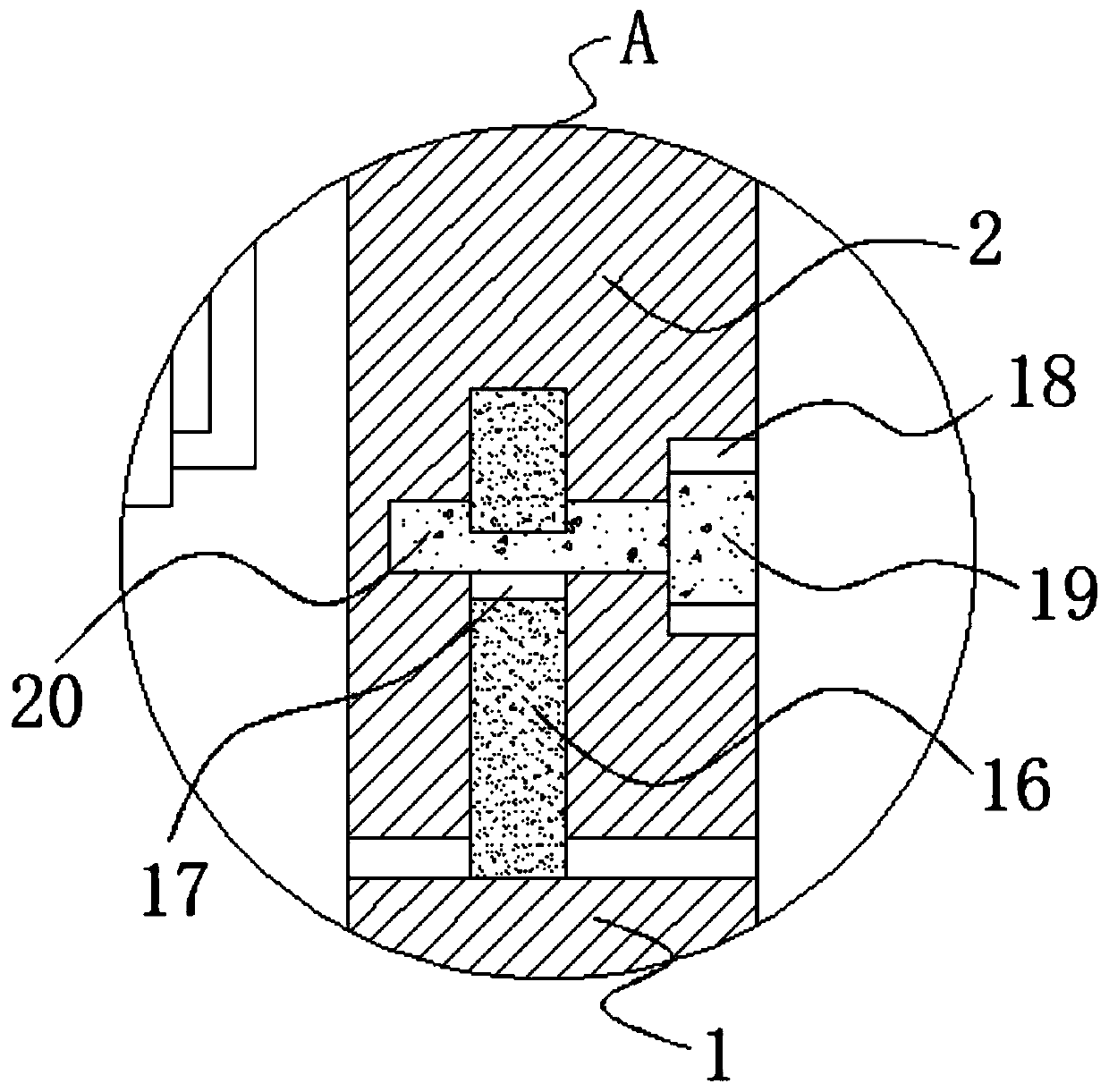

ActiveCN112787025ARealize cooling operationPlay a buffer roleBattery isolationSecondary cellsEngineeringMechanical engineering

The invention relates to the technical field of fluorine ion batteries, in particular to a mounting rack capable of carrying a fluorine ion battery and a use method of the mounting rack. The mounting rack comprises a mounting rack body and a buffer mechanism arranged at the bottom of the mounting rack body, the mounting rack body comprises a mounting plate, a fluorine ion battery body is arranged at the top of the mounting plate, a sliding plate is arranged at the bottom of the mounting plate, a sealing plate is arranged at the bottom of the sliding plate, sealing strips are clamped to the periphery of the sealing plate, a cooling mechanism is arranged on the periphery of the buffer mechanism and comprises a cooling outer box, and a cover plate is arranged on the top of the cooling outer box. Water in an overflow cavity enters the cooling cavity through a water pump to form backflow, a condenser condenses and cools the water in the backflow process to enable the water to become low-temperature water, the low-temperature water enters the overflow cavity and is mixed with high-temperature water to cool the water to enter the buffer inner box through the through groove, and the fluorine ion battery body is cooled through the buffer inner box, so that the cooling operation is realized.

Owner:石家庄锶源科技有限公司

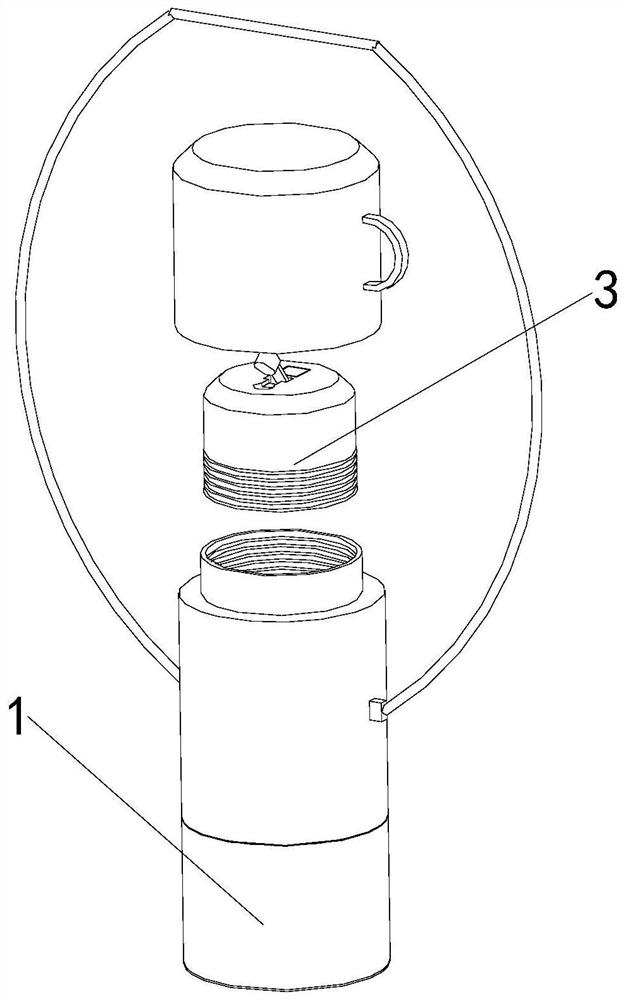

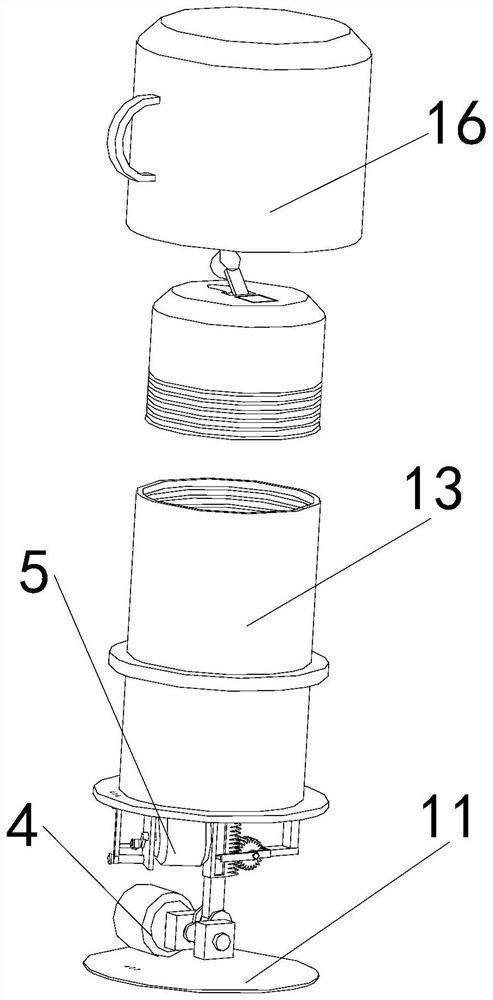

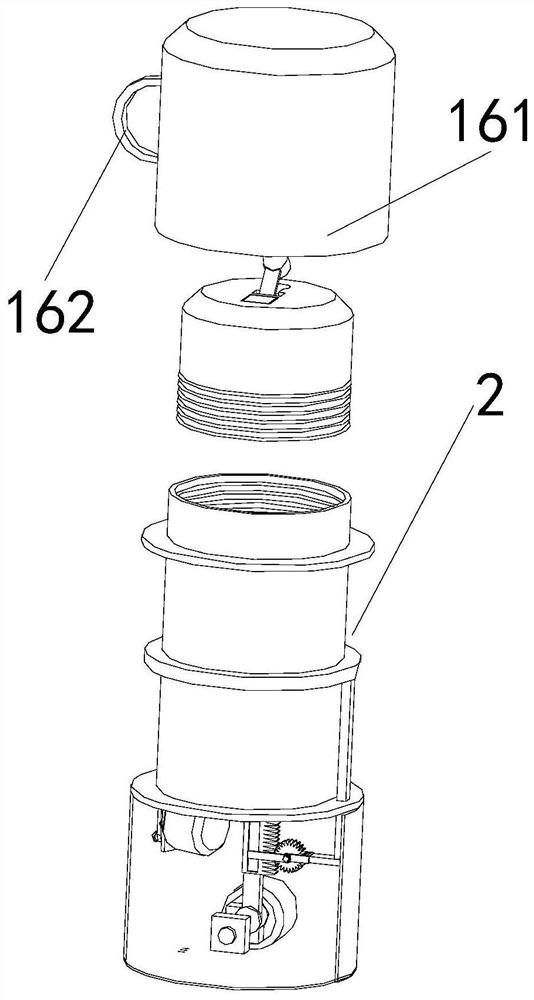

Automatic heating and cooling vacuum cup

InactiveCN112603135AEasy to chokeRealize automatic heating and coolingDrinking vesselsEngineeringHeat conservation

The invention discloses an automatic heating and cooling vacuum cup, and belongs to the technical field of automatic heating and cooling. The vacuum cup comprises a vacuum cup device, a compression piston device, a sealing device and a cup head device, the vacuum cup device is horizontally arranged, and the compression piston device is arranged in the vacuum cup device; and the sealing device is arranged in the vacuum cup device and located on one side of compression piston device, and the cup head device is arranged in the vacuum cup device. After hot water is manually introduced into the vacuum cup, when water needs to be drunk, the vacuum cup is automatically cooled so that people can drink the hot water. The water in the vacuum cup can be continuously cooled as time goes on, at the moment, the vacuum cup is automatically heated to reach the temperature at which people can drink, and heat preservation is conducted.

Owner:顾陈陈

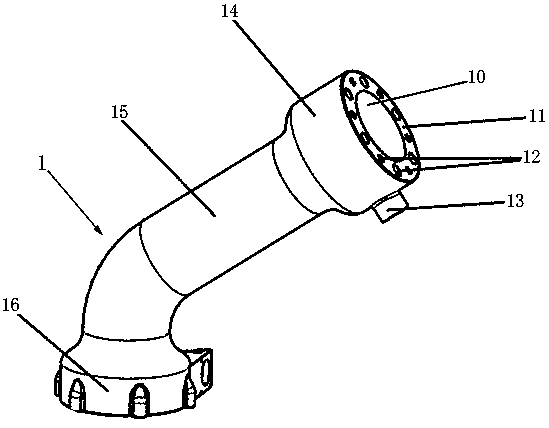

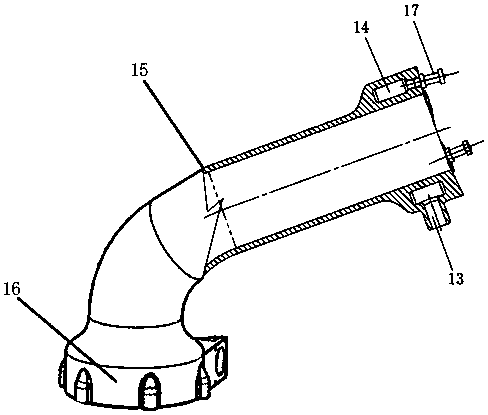

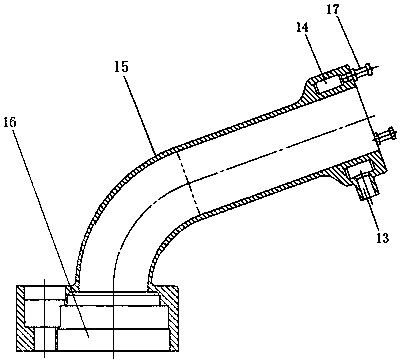

Wind conveying spray gun capable of achieving dust suppression and haze removal

PendingCN110721845AExpand the atomization rangeAchieve dust suppressionUsing liquid separation agentSpraying apparatusAir volumeAtomizer nozzle

The invention discloses a wind conveying spray gun capable of achieving dust suppression and haze removal. The wind conveying spray gun capable of achieving dust suppression and haze removal comprisesa wind cylinder (15), the wind cylinder (15) is a bent pipe, the lower end of the wind cylinder (15) is a rotation joint (16), an air outlet (10) is formed in the top of the wind cylinder (15), a mist spraying device is arranged on the air outlet, a water inlet leading pipe (13) communicates with the mist spraying device, a rotating mechanism (2) an a connecting pipe (3) are included, the lower bottom end of the connecting pipe (3) is a connecting flange, a straight pipe on the upper segment of the connecting pipe (3) is inserted into a main connector of the rotation joint (16), and the rotation joint (16) is assembled with the rotating mechanism (2). The wind conveying spray gun has the advantages that after an atomizing nozzle is arranged, water mist can be blown following the wind, wind energy and injection water energy are subjected to superposition, under the equal wind condition, the water mist blowing distance is prolonged, under the same blowing distance, the wind amount is small, the water consuming amount is small, and the energy consumption is greatly reduced.

Owner:重庆嘉天环保工程有限公司

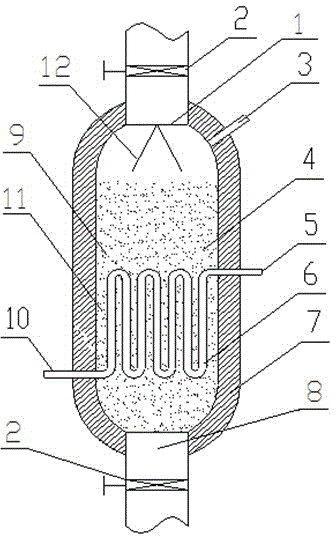

Rotary kiln magnetizing roasting heat-source-free continuous reduction apparatus and use method

The present invention relates to the technical field of smelting equipment, and discloses a rotary kiln magnetizing roasting heat-source-free continuous reduction apparatus and a use method. The rotary kiln magnetizing roasting heat-source-free continuous reduction apparatus comprises a tank, a material inlet and a material outlet, wherein the upper cavity of the tank is a continuous reduction region, the lower cavity is a heat exchange region, a heat exchange pipe is arranged in the heat exchange region, the heat exchange pipe inlet end is arranged on the lower side of the tank wall of the tank, the heat exchange pipe outlet end is arranged on the middle portion of the tank wall of the tank, the upper cavity tank wall of the tank is further provided with a reduction coal gas outlet, and the material inlet end and the rotary kiln outlet end are connected. According to the present invention, after being subjected to 20-30% of pre-reduction in the rotary kiln, iron ore enters the tank of the apparatus, the high temperature waste heat of the iron ore is utilized to carry out heat-source-free continuous reduction so as to complete the remaining 70-80% of the reduction process, and the obtained material is cooled to a temperature of less than 200 DEG C through the heat exchange region so as to be discharged. According to the invention, the roasting time of the iron ore in the rotary kiln is reduced, the rotary kiln productivity is increased, the reduction carbon consumption is reduced, the CO content in the rotary kiln flue gas is reduced, and energy saving and emission reduction are effectively achieved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

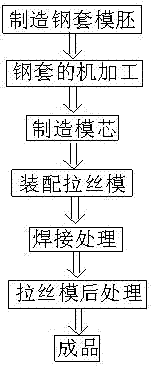

Wire drawing mould manufacturing method capable of implementing water cooling treatment

InactiveCN103495616AProcess arrangement is reasonableEasy to implementDrawing profiling toolsWater circulationWater cool

The invention discloses a wire drawing mould manufacturing method capable of implementing water cooling treatment. The manufacturing method comprises the following steps of: (a) manufacturing a steel sleeve mould blank; (b) machining a steel sleeve; (c) manufacturing a mould core; (d) assembling a wire drawing mould; (e) carrying out welding treatment; (f) carrying out the post processing of the wire drawing mould. The wire drawing mould manufacturing method capable of implementing the water cooling treatment, which is disclosed by the invention, is reasonable in procedure arrangement, easy and convenient to implement and moderate in cost. A mould core prepared according to the manufacturing method is high in accuracy and is stable in connection with the steel sleeve; a spiral groove structure inside the steel sleeve can be used together with an external water circulation system, so that the whole wire drawing mould is cooled, the forming temperature of a wire is effectively controlled, the phenomenon of wire fracture is prevented in a drawing process, and the processing quality and processing efficiency of the wire are enhanced.

Owner:SUZHOU YIQUN MOLD

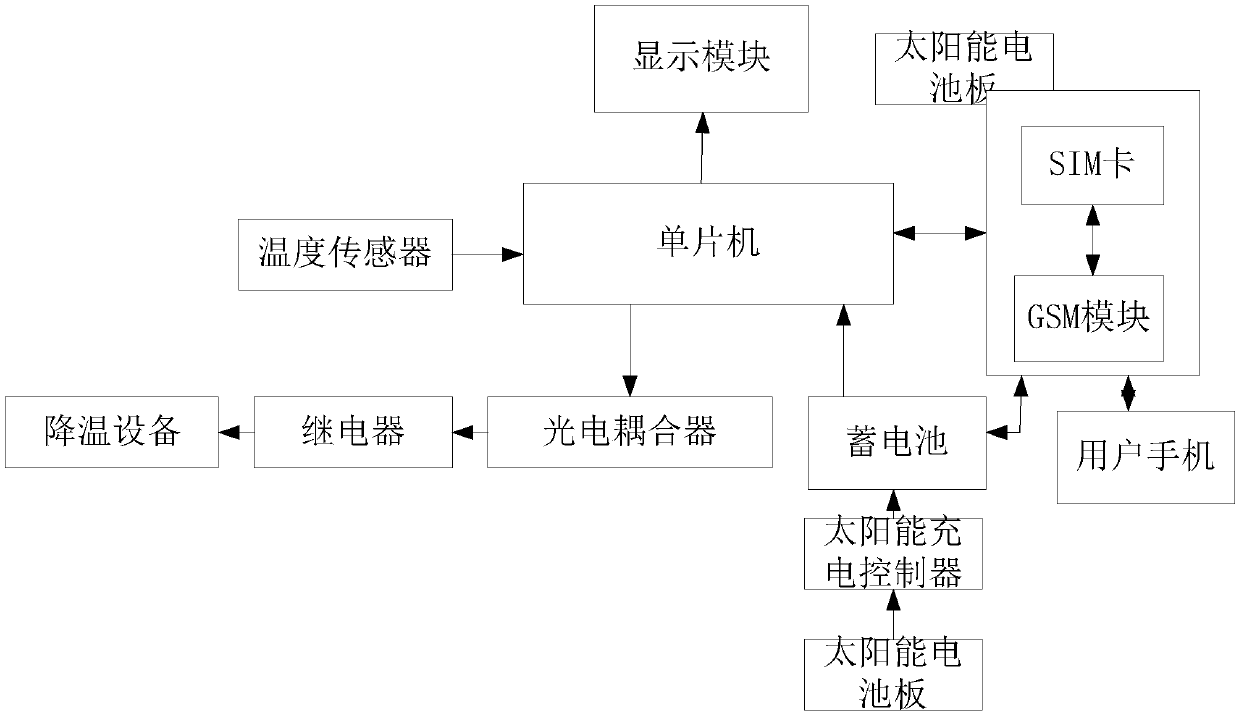

Energy conservation and environment protection type remote cooling device

The invention discloses an energy conservation and environment protection type remote cooling device. The energy conservation and environment protection type remote cooling device comprises a singlechip microcomputer, a photoelectric coupler, a temperature sensor, a SIM card, a GSM module and a user mobile phone, wherein the SIM card and the GSM module are interconnected, a wireless communicationunit composed of the SIM card and the GSM module simultaneously performs communication connection with the singlechip microcomputer and the user mobile phone; the temperature sensor is connected on the singlechip microcomputer, the singlechip microcomputer is also connected with a display module, and the wireless communication unit composed of the SIM card and the GSM module and the singlechip microcomputer both are powered by a storage battery; the photoelectric coupler is also connected with the singlechip microcomputer, and a relay and cooling equipment are orderly connected on the photoelectric coupler; and the storage battery, a solar battery charging controller and a solar battery panel are connected orderly. Based on the principles above, the energy conservation and environment protection type remote cooling device provided by the invention reads short message content and a mobile phone number through the GSM module, realizes a cooling operation and simultaneously supplies powerthrough electric energy generated by the solar battery panel, and thus, energy conservation and environment protection is realized.

Owner:邵曦

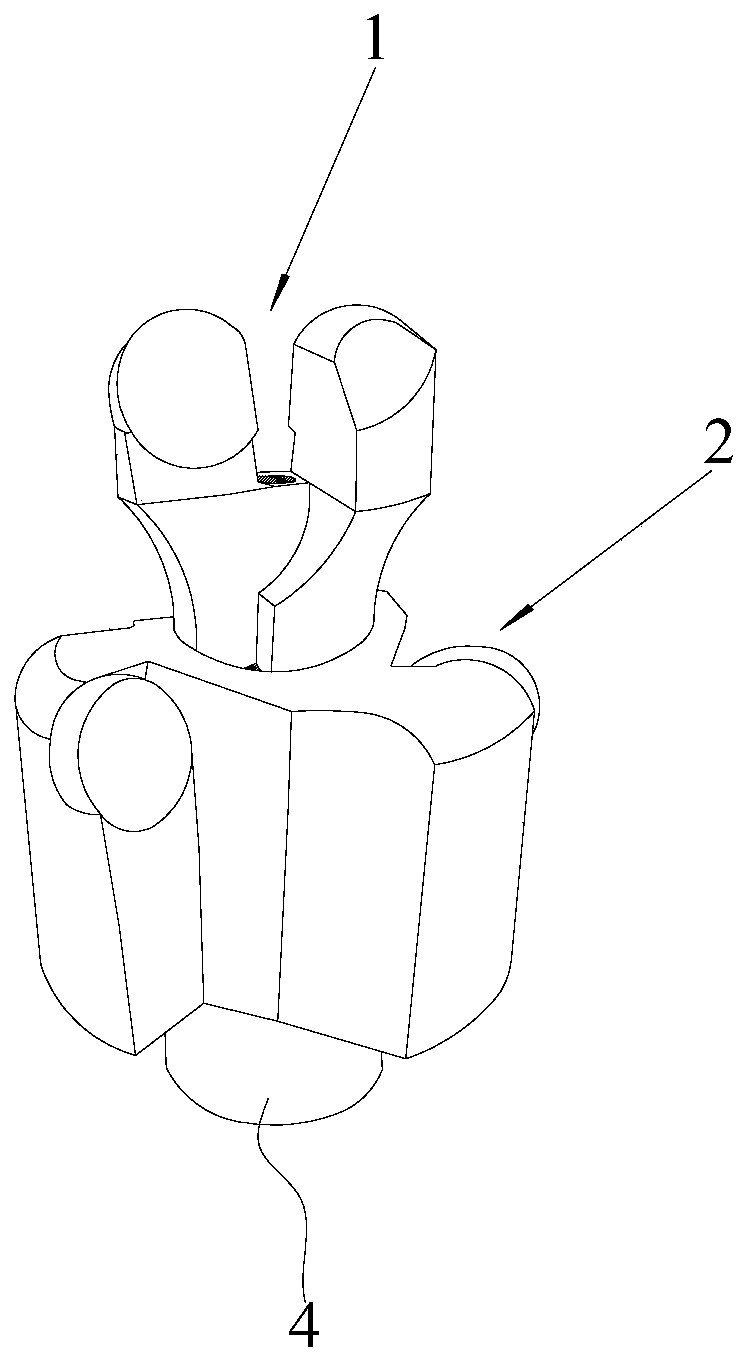

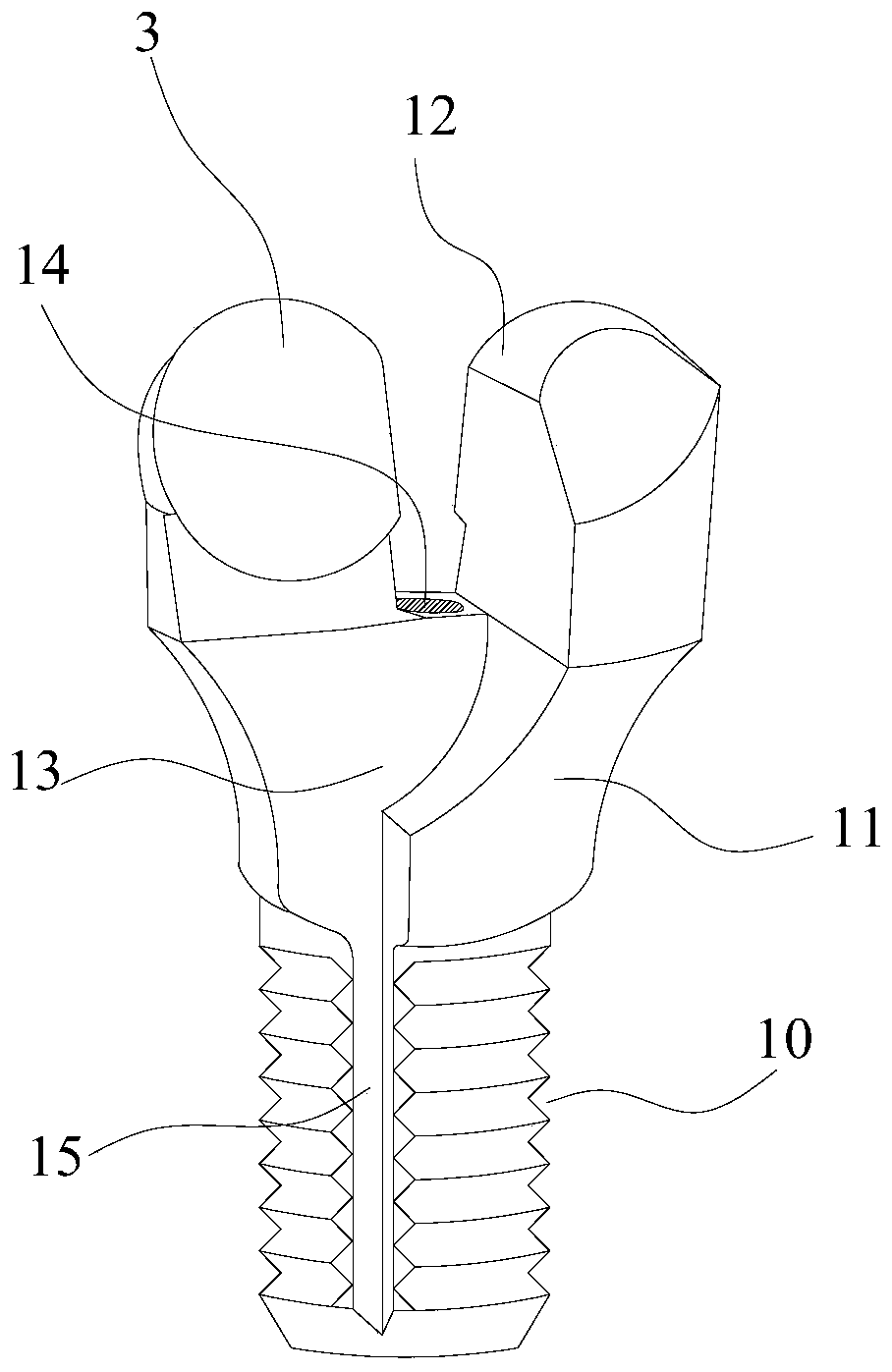

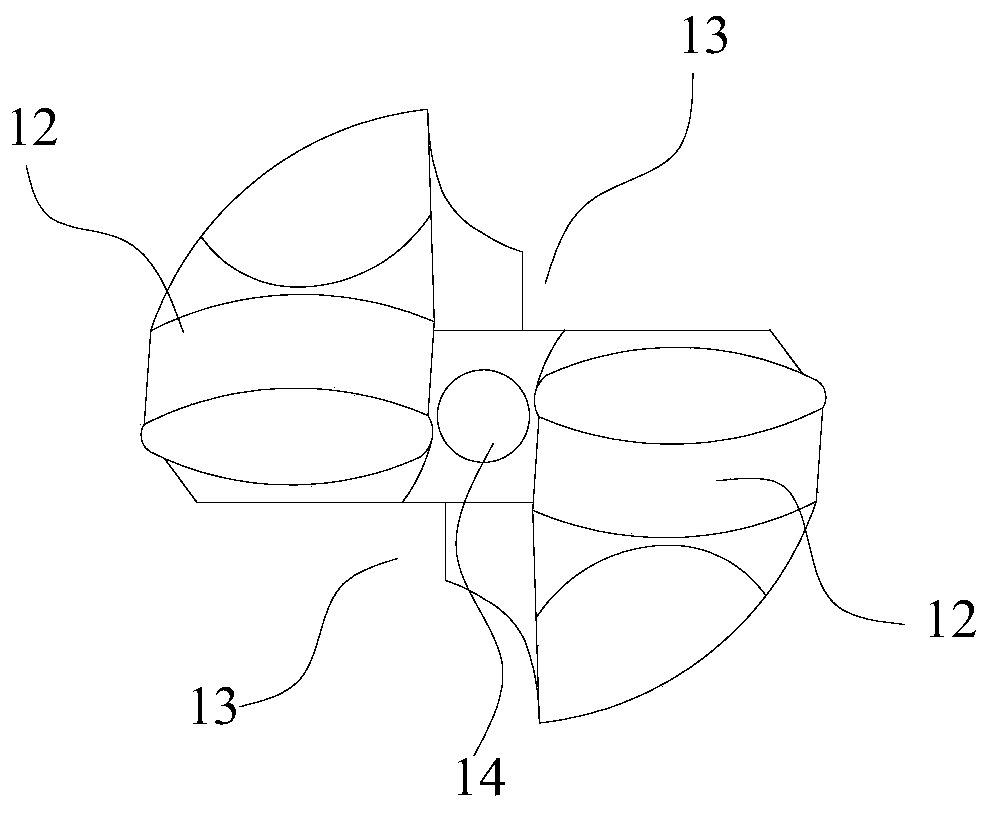

Combined drill bit structure for anchor rod/anchor cable drilling and construction method thereof

The invention discloses a combined drill bit structure for an anchor rod / anchor cable drilling and a construction method thereof. The combined drill bit structure comprises a guide drill bit assemblyand a reamer bit assembly connected below the guide drill bit assembly in a matched mode, wherein the radial size of the guide drill bit assembly is smaller than that of the reamer bit assembly. The combined drill bit structure has the advantages of being reliable in structure, good in use performance, high in drilling efficiency and good in hole forming quality, and the problems of hole shrinkage, hole collapse and poor hole forming quality of high-low stress weak surrounding rocks are effectively avoided.

Owner:杭州图强工程材料有限公司 +1

A switchgear with an inner and outer two-layer cabinet structure

InactiveCN105680353BLarge installation spaceImprove cooling effectSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringTwo layer

The invention discloses a switch cabinet with inner and outer cabinet bodies, which comprises an inner cabinet body and an outer cabinet body arranged outside the inner cabinet body, wherein both the inner cabinet body and the outer cabinet body are provided with cabinet doors; the top part of the outer cabinet body is provided with a top cover; the bottom part of the inner cabinet body is provided with a base; a cavity is formed between the outer wall of the inner cabinet body and the inner wall of the outer cabinet body; a vent pipe is arranged in the cavity; the vent pipe is clamped on the inner wall of the outer cabinet body via a buckle; the end surface of one side, facing the inner cabinet body, of the vent pipe is provided with a vent hole; and the lower end of the top cover is provide with a support. Ventilation is realized through adopting the vent pipe, the fact that the inner part of the cabinet body is likely to be affected with damp when a vent window structure is arranged is avoided, the cabinet body structure whose inner layer and the outer layer can be adjusted is adopted, the two layers of cabinet bodies can move relatively when needed, a structure with two vertical cabinet bodies is thus formed, and the space for mounting an electric appliance is increased.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +2

A high and low voltage switchgear with protective performance

ActiveCN114256769BGuaranteed protective effectRealize cooling operationSubstation/switching arrangement cooling/ventilationFire rescueLow voltageHeat Avoidance

The invention relates to the field of electrical cabinet equipment, and discloses a high and low voltage switchgear with protective performance, which is used for installing an electrical cabinet shell of electrical equipment. In the installation cavity of the device, a plurality of installation cavities are also provided with retractable airbags for driving the movement of the telescopic plates, and a pneumatic component capable of spraying dry powder in a plurality of single cabinets is also installed on the installation frame. By shrinking the installation cavity, the invention avoids the expansion of danger caused by factors such as heat conduction, and at the same time, when the telescopic plate moves to the maximum extent, it just completely covers the heat dissipation hole, which further ensures the sealing of the installation cavity in the event of an emergency, and strictly controls the expansion of danger. , and can also be covered by dry powder to isolate the open flame and exhaust air to prevent the occurrence of fire in the single cabinet, so as to further protect the electrical cabinet to fully ensure the safety of its use.

Owner:泰山科学技术研究院

Cooking utensil

PendingCN111493683ARealize cooling operationAvoid heat damageSteam cooking vesselsCooking utensils shields/jacketsThermodynamicsThermal water

The invention provides a cooking utensil. According to the cooking utensil, a waterway plate is arranged between a furnace pipe and an outer frame, the waterway plate can guide external cooling waterinto the waterway plate through a first water inlet, the cooling water further acts on the furnace pipe so as to absorb heat on the furnace pipe, and the generated hot water can be further dischargedout of the cooking utensil through a first water outlet and a second water outlet. By means of the structure, cooling operation of the furnace pipe can be achieved firstly, and then devices on the outer wall of the furnace pipe can be prevented from being damaged by high temperature; and secondly, by arranging the waterway plate, redundant heat can be transferred into cooling water, the temperature of the heated cooling water is increased, subsequent use can be conducted, and thus the heat utilization rate in the furnace pipe is effectively increased.

Owner:GREE ELECTRIC APPLIANCES INC

Engine cooling device

InactiveCN112627961ARealize the work of ventilationRealize multi-angle water spraying operationInternal-combustion engine testingMachines/enginesEngineeringAir exchange

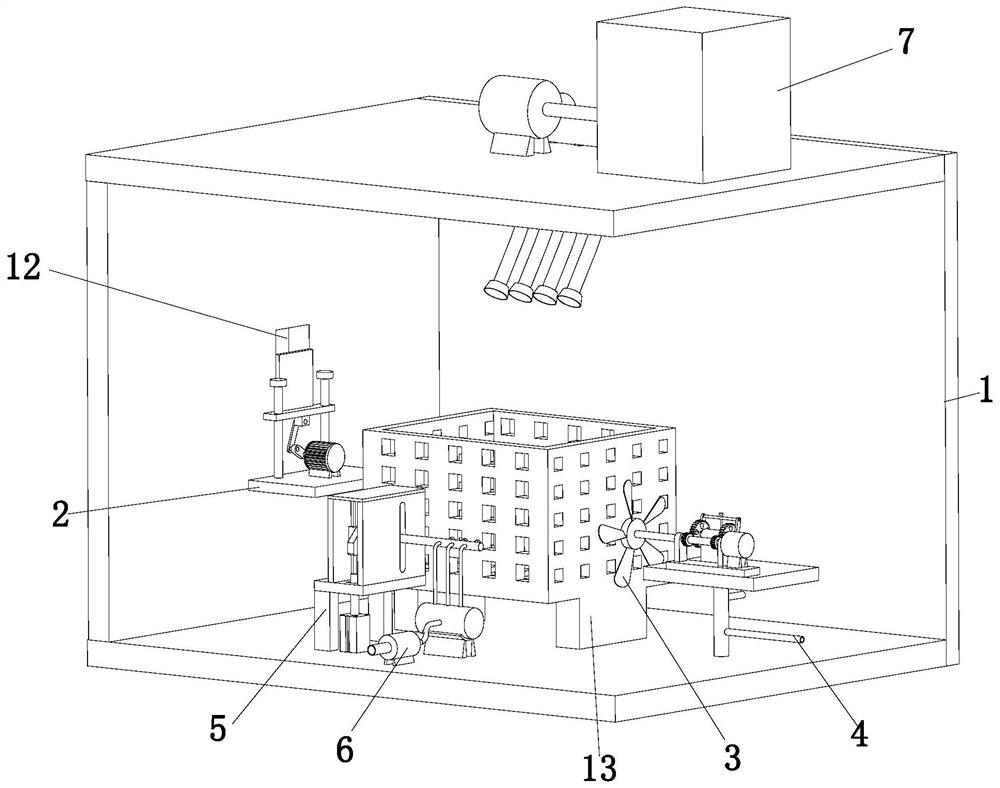

The invention discloses an engine cooling device, and belongs to the technical field of engine cooling. The engine cooling device comprises a cooling box, a ventilation assembly, an air cooling assembly, an air exchange assembly, a swing assembly, a water cooling assembly and a spraying assembly, the cooling box is horizontally placed on a horizontal plane, an engine placement frame is arranged in the cooling box, the ventilation assembly is horizontally arranged on the inner side wall of the cooling box and located below a ventilation opening, the air cooling assembly is arranged on the other side wall of the cooling box, the air exchange assembly is arranged beside the air cooling assembly, the swing assembly is horizontally arranged at the inner bottom of the cooling box, the water cooling assembly is fixedly connected to the inner bottom of the cooling box and located beside the swing assembly, the spraying assembly is arranged at the top of the cooling box, and the spraying end of the spraying assembly penetrates through the top of the cooling box and extends to the position above the engine placement frame. According to the engine cooling device, various cooling modes of the engine are achieved through the air cooling assembly, the air exchange assembly, the water cooling assembly and the spraying assembly.

Owner:余小翠

A dual-disc brake disc for a high-performance car

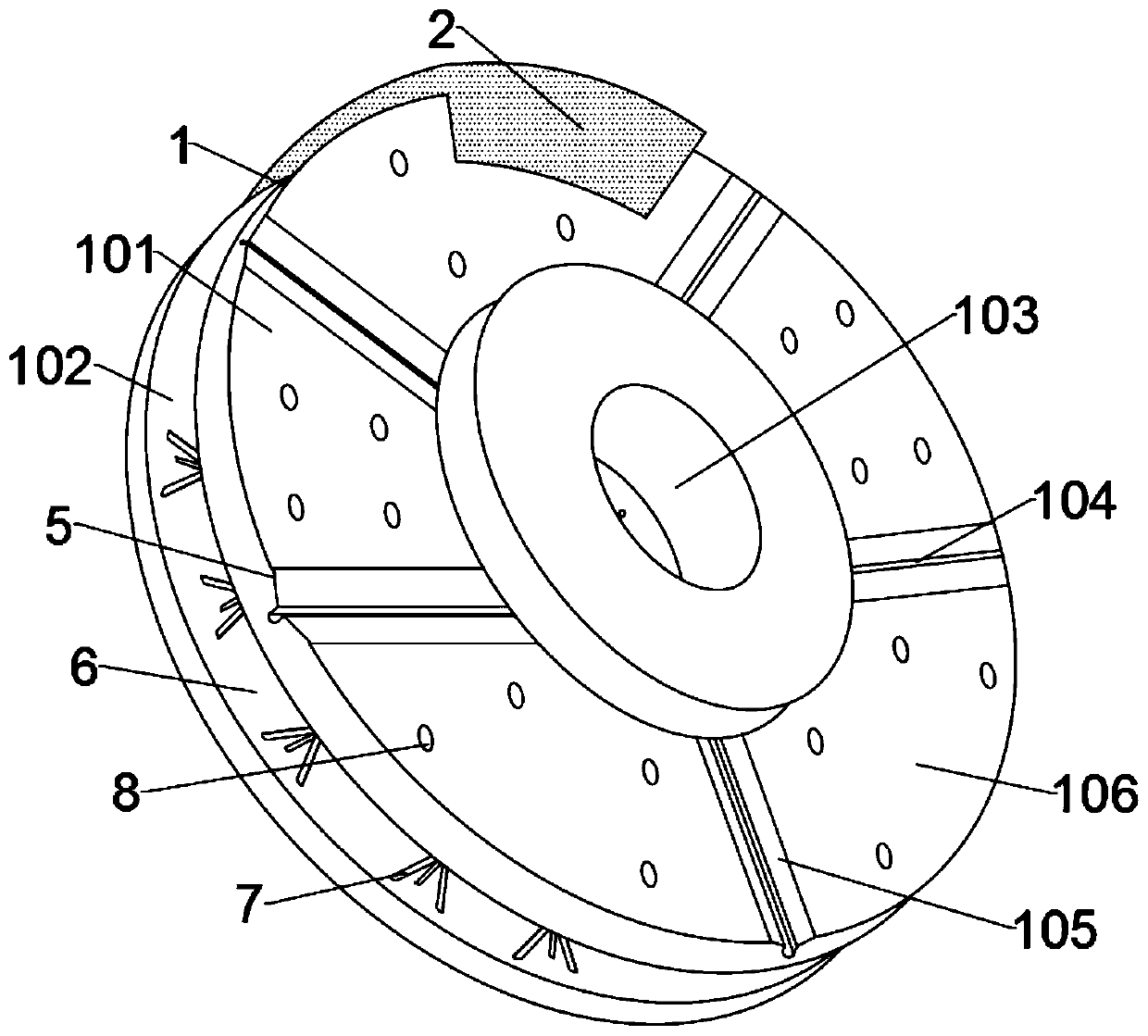

ActiveCN110410434BDoes not affect brake operationExtended service lifeBraking discsBraking membersStructural engineeringMechanical engineering

The embodiment of the invention discloses a dual-disc brake disc of a high-property vehicle. The brake disc comprises a brake disc body and a brake clamp. The brake disc body comprises a first brake disc, and a second brake disc in direct-facing connection with the first brake disc, a mounting inserting hole is arranged in a manner of penetrating through the center positions of the first brake disc and the second brake disc, multiple evenly-distributed radiation dust storage grooves are formed in a round groove concentric with the mounting inserting hole, sinking concave groove blocks which are the same in area and size are formed in the two sides of each radiation dust storage groove, the first brake disc and the second brake disc are each divided into multiple plane fan-shaped blocks with the same area, and the plane fan-shaped blocks are arranged between two adjacent sinking concave groove blocks. The dust collecting groove is added on the brake disc, the dust is concentrated into the grooves to be thrown out during brake disc rotating, normal brake operation of the brake disc is not affected, wear caused by brake is reduced, and the service life of the brake disc is prolonged.

Owner:莱州伟辰汽车配件有限公司

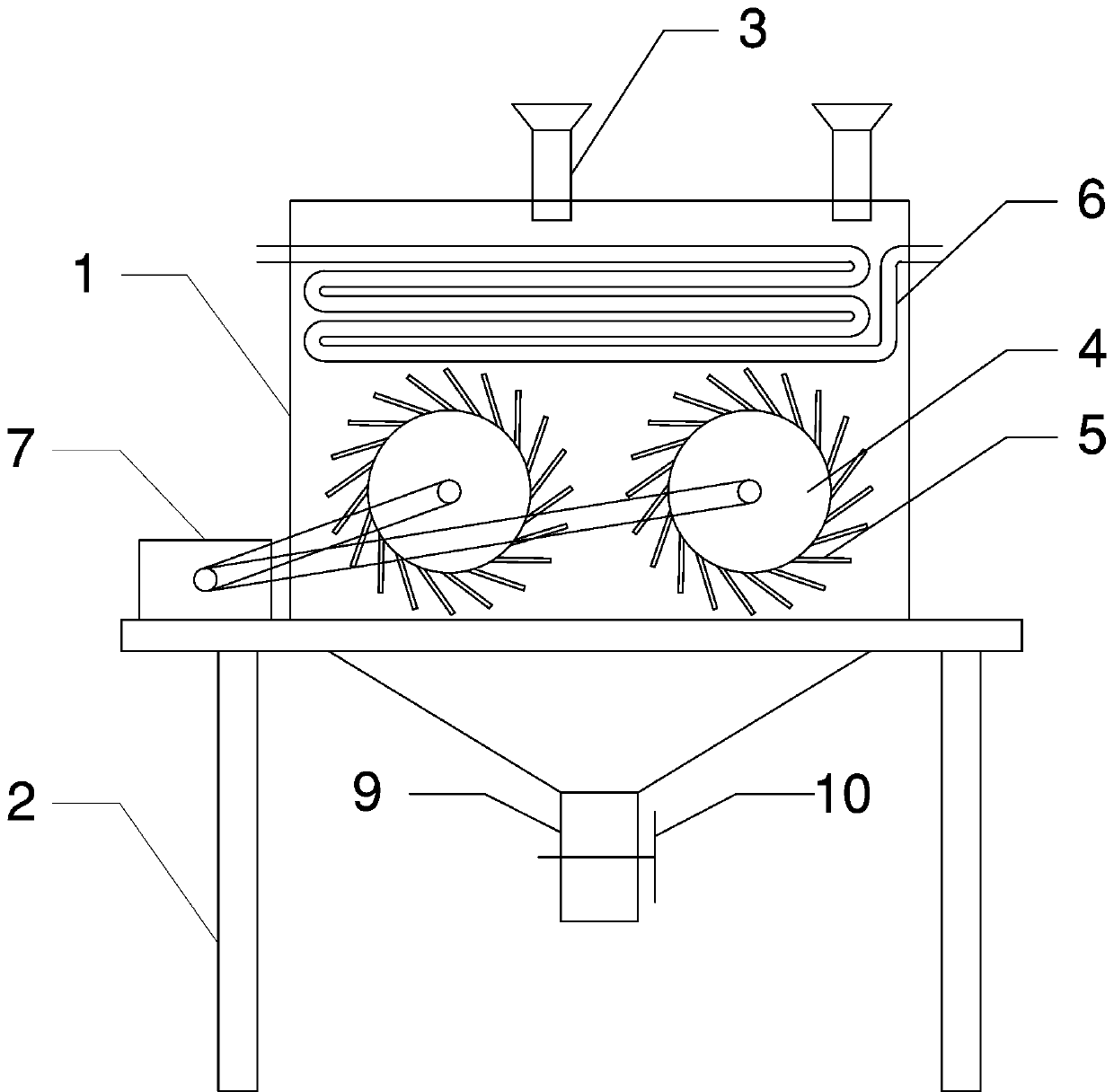

Cement cooling device

InactiveCN109974476AReduce stack cooling timeImprove factory speedStationary conduit assembliesEngineeringMoisture

The invention relates to a cement cooling device. The cement cooling device comprises a drying chamber, wherein the drying chamber is fixedly arranged on a bracket; a rotating drum is arranged in thedrying chamber; a rotating shaft of the rotating drum is horizontally arranged; a feeding hopper is arranged at the top of the rotating drum; a downward extension line of a discharging end of the feeding hopper is tangent to the rotating drum; a plurality of rubber belts are arranged on the outer wall of the rotating drum; and one ends of the rubber belts are fixedly connected with the outer wallof the rotating drum. By adopting the structure, rapid cooling after cement production can be realized, cement stacking time is reduced, waste caused by cement moisture is avoided, and the supply efficiency of manufacturers is improved.

Owner:枝江市美力坚水泥制品有限公司

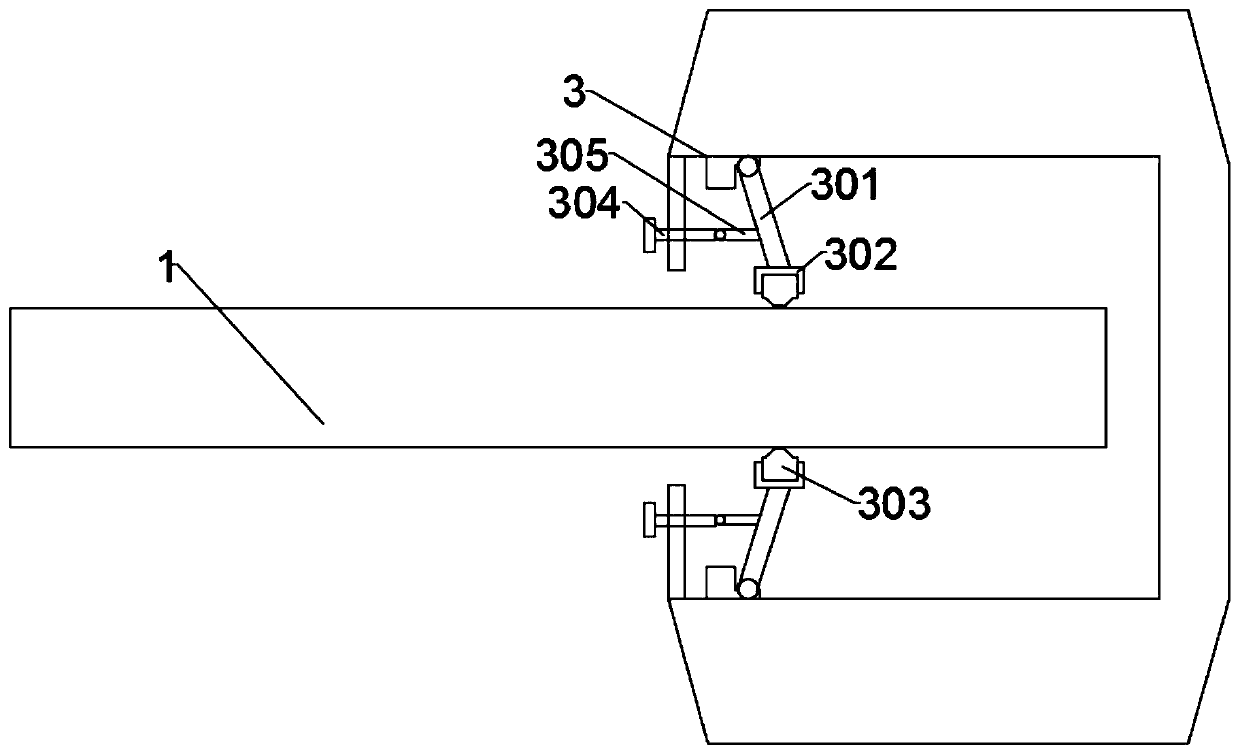

Conveying passage in rotor shelling device

InactiveCN107222069ARealize the shelling operationRealize cooling operationManufacturing stator/rotor bodiesEngineeringTorsion spring

The invention discloses a conveying channel on a rotor shelling device, which comprises a vertical channel, two arc-shaped grooves penetrating the inner wall of the vertical channel are formed on the outer wall of the vertical channel up and down, and the vertical channel is inserted into the There is a circular baffle matched with the arc-shaped groove, the upper baffle is provided with a first pressure sensor, and the side wall of the baffle is formed with lugs passing through the arc-shaped groove, and the lugs are fixed by inserting sleeves On the articulated shaft, a return torsion spring is sleeved on the articulated shaft; an arc-shaped protective cover is fixed on the outer wall of the vertical channel around the arc-shaped groove on the upper side of the vertical channel, and an arc-shaped protective sleeve is arranged on the outer wall of the protective cover. There is an indicator light, an arc-shaped elastic plate is fixed inside the protective cover, and a second pressure sensor is arranged on the elastic plate. The indicator light is connected with the second pressure sensor and the first pressure sensor, and the indicator light can display the first pressure sensor. Indicator color and secondary indicator color. The invention can not only facilitate the shelling treatment of the rotor, but also prevent personnel from being injured.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Mounting structure of electronic component

InactiveCN110769623ATo achieve a fixed connection positionThere will be no phenomenon of displacement and sheddingCasings/cabinets/drawers detailsSmall component housingsEngineeringStructural engineering

The invention discloses a mounting structure of an electronic component. The mounting structure comprises a mounting base, connecting inserting rods are fixedly connected with the two sides of the lower surface of the mounting base respectively, and can be fixedly connected on the surface of a PCB, the upper end of the mounting base is fixedly connected with an upper cover, heat dissipation platesare fixedly arranged at the middle portion of the inner surface of the mounting base and are fixedly arranged at the upper portion of the inner surface of the mounting base at an equal intervals, andvent holes are fixedly formed in the upper surface of the mounting base and penetrate the lower surface of the mounting base. In the present invention, the mounting structure of the electronic component is directly fixed on the PCB, the electronic component is fixed in the structure to achieve fixing of the position of the electronic component, and connecting insertion holes with different distances are fixedly formed in the structure and matched with joint operation of the upper compression part, so that fixed connecting positions are provided for electronic components of different sizes; and moreover, the upper portion and the lower portion of the structure are fixedly arranged in a butt joint mode, butt joint holes are formed in the structure, the butt joint mode is simple, and simpledisassembling, maintaining and replacing operation is achieved.

Owner:徐州陀微传感科技有限公司

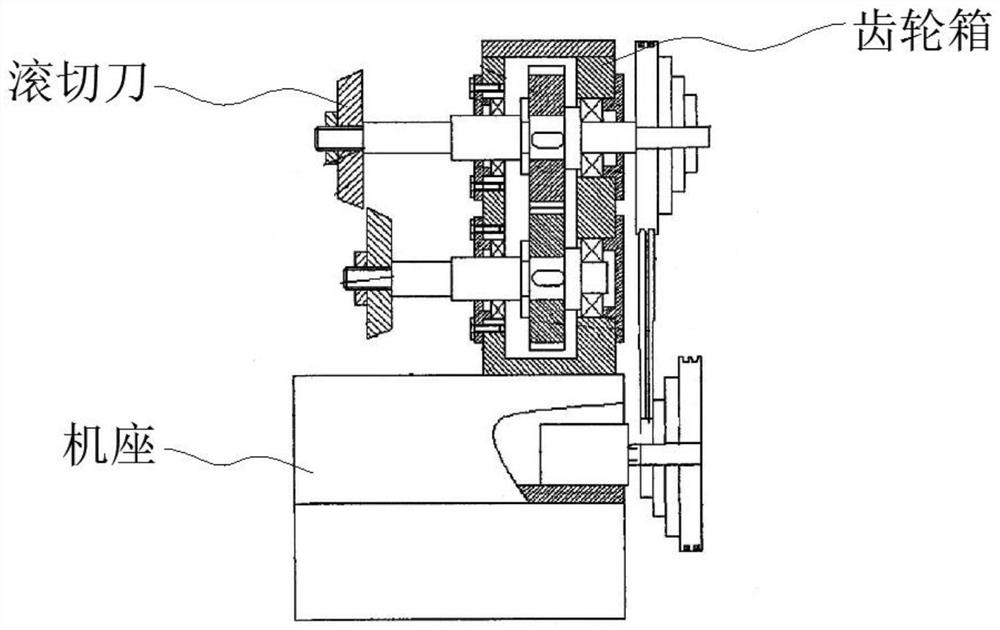

Hobbing type plate shearing machine

PendingCN114309762AImprove stabilityReduce distortionShearing machinesMaintainance and safety accessoriesHobbingElectric machinery

The hobbing type plate shearing machine comprises a plate shearing operation table, a plate shearing through opening is formed in the middle of the plate shearing operation table, a knife rest is arranged above the plate shearing through opening, a transmission rod is rotationally connected to the inner wall of the knife rest, a hobbing knife is slidably connected to the middle of the transmission rod, and a driving box is fixedly installed on one side of the knife rest; a driving motor is fixedly mounted in the driving box, and the output end of the driving motor is in transmission connection with one end of a transmission rod; the two bearing rollers are supported through the U-shaped supporting frame and are symmetrically distributed on the two sides of the bearing knife roll, the bearing knife roll is assisted to provide support for plates, the stability of the plates in the cutting process is enhanced, distortion of the plates is reduced, and the flatness of cut finished plates is improved; the bearing knife roll and the hobbing knife are arranged to be in sliding connection, so that the bearing knife roll and the hobbing knife can be correspondingly adjusted according to the actual plate cutting position requirement, and the use flexibility of the device is improved.

Owner:安徽省华夏机床制造有限公司

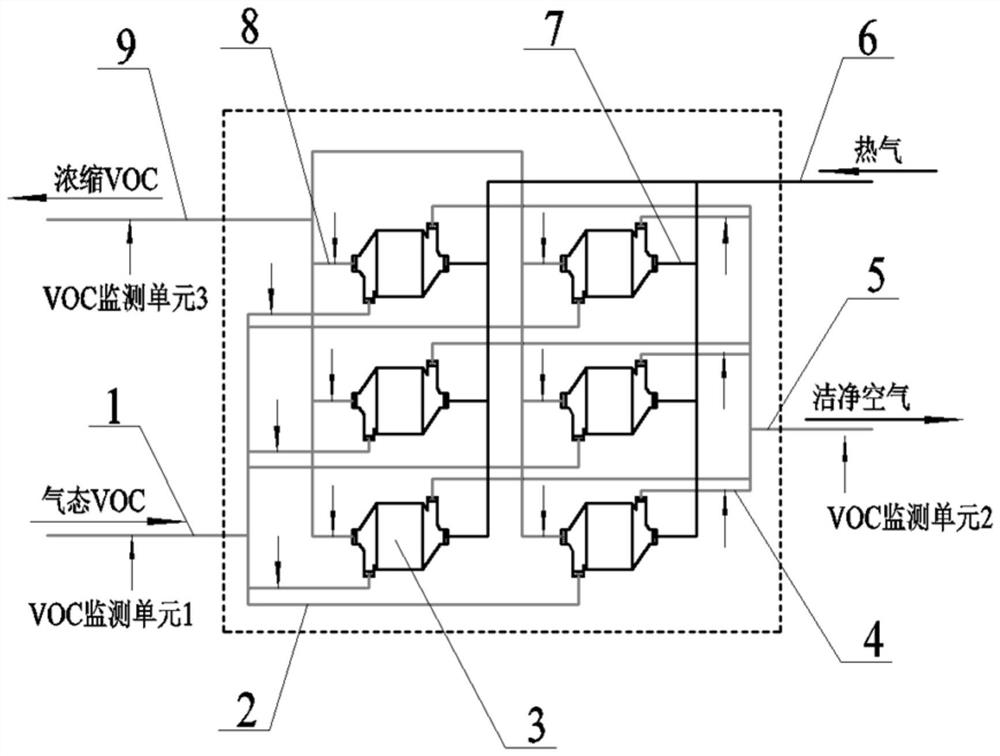

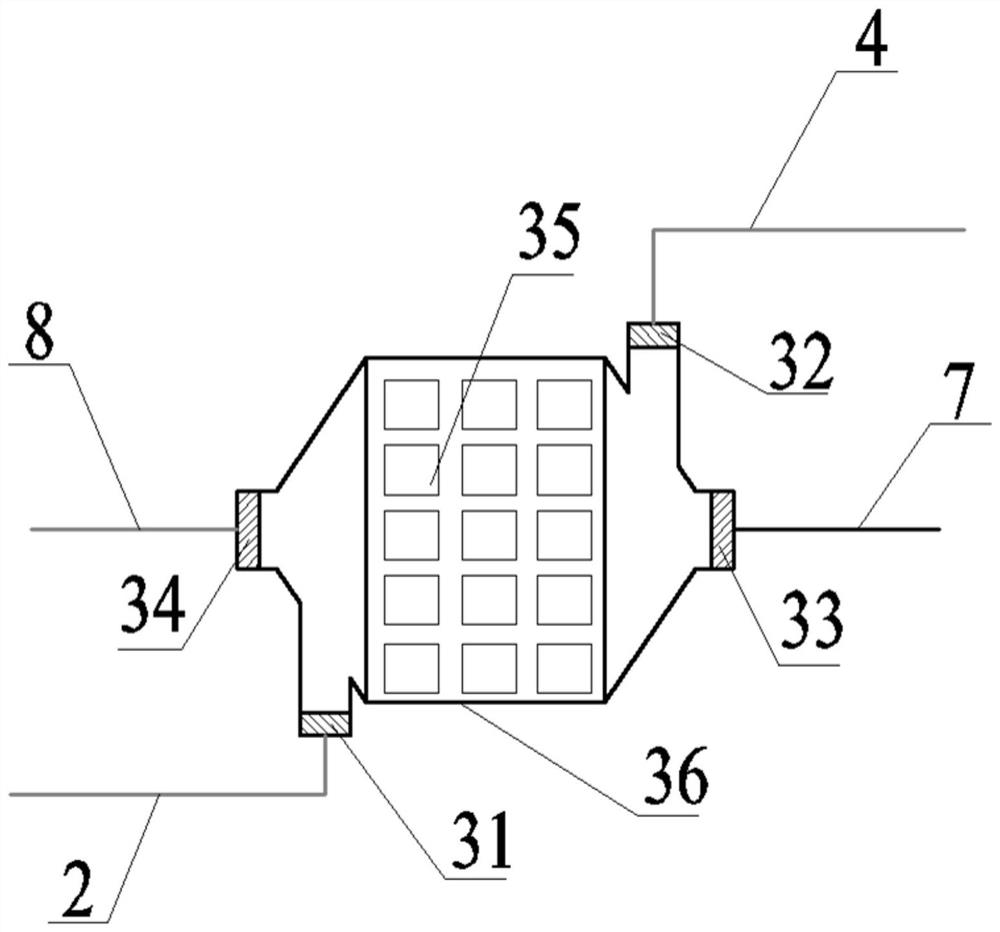

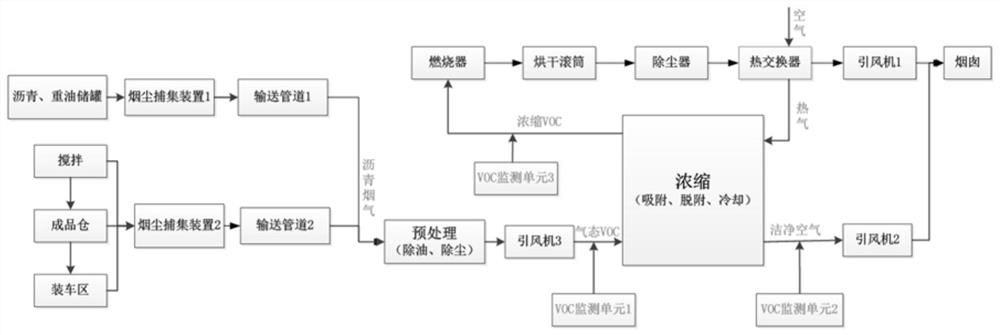

Asphalt flue gas concentration device, system and method

PendingCN113457368ARealize the adsorption processRealize desorption operation processCombination devicesGas treatmentThermodynamicsAir volume

The invention discloses an asphalt flue gas concentration device, system and method.The device comprises an adsorption / desorption module, the adsorption / desorption module comprises a box body and an adsorption material arranged in the box body, and the box body is connected with a VOC input valve, a clean air output valve, a desorption hot gas input valve and a concentrated VOC output valve; the VOC input valve and the concentrated VOC output valve are located on one side of the adsorption material, and the clean air output valve and the desorption hot air input valve are located on the other side of the adsorption material; and according to the designed concentration device, the operation processes of adsorption, desorption, cooling and the like can be automatically switched through opening and closing of the valves, large-air-volume low-concentration asphalt flue gas can be converted into small-air-volume high-concentration flue gas, and the influence on a combustion-drying-dust removal system is reduced.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

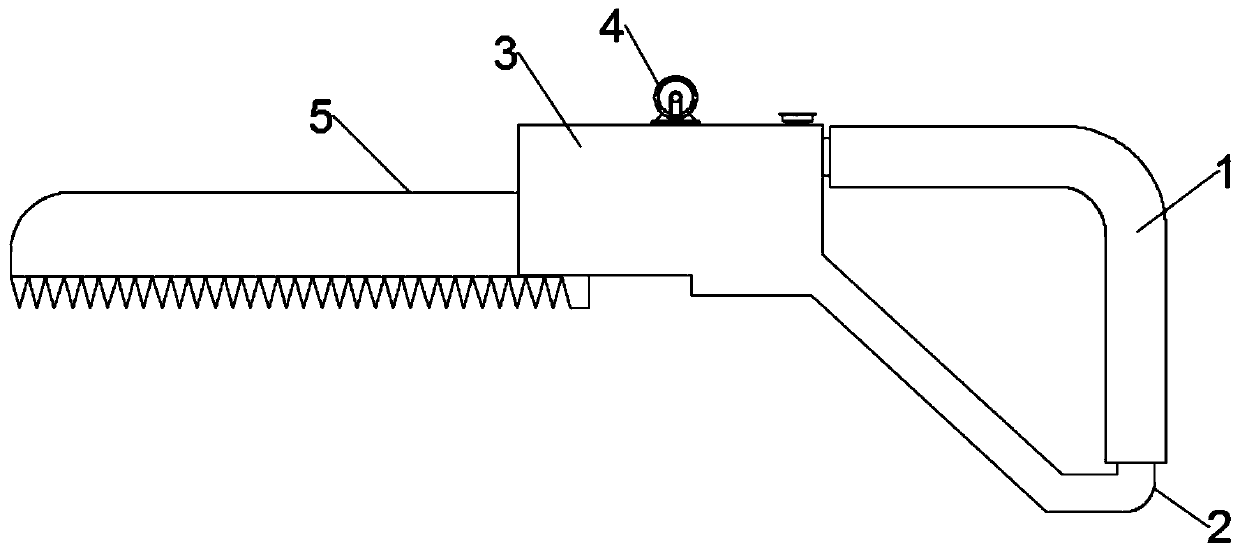

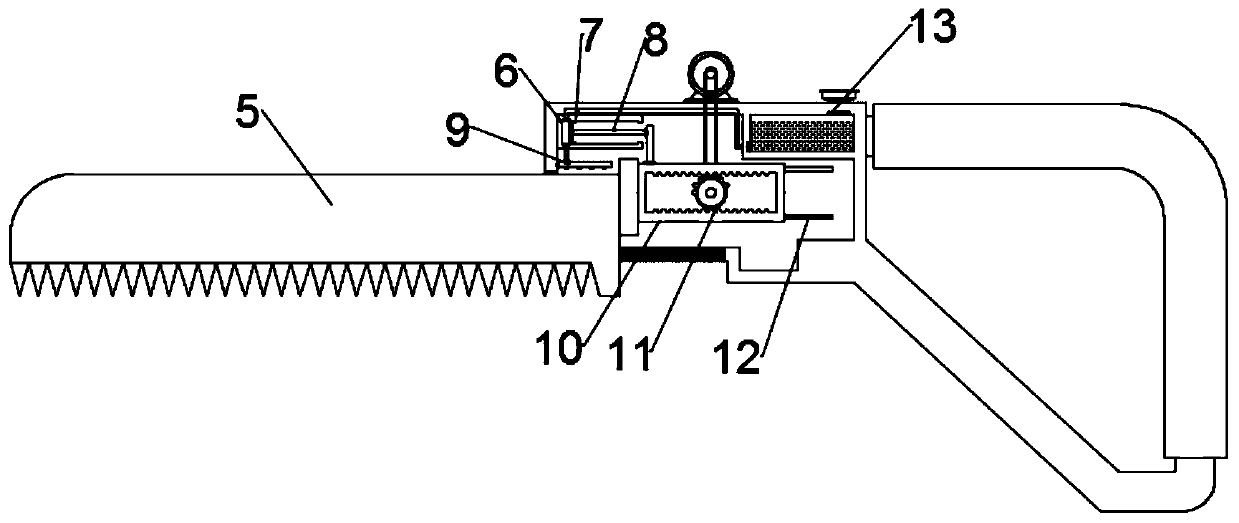

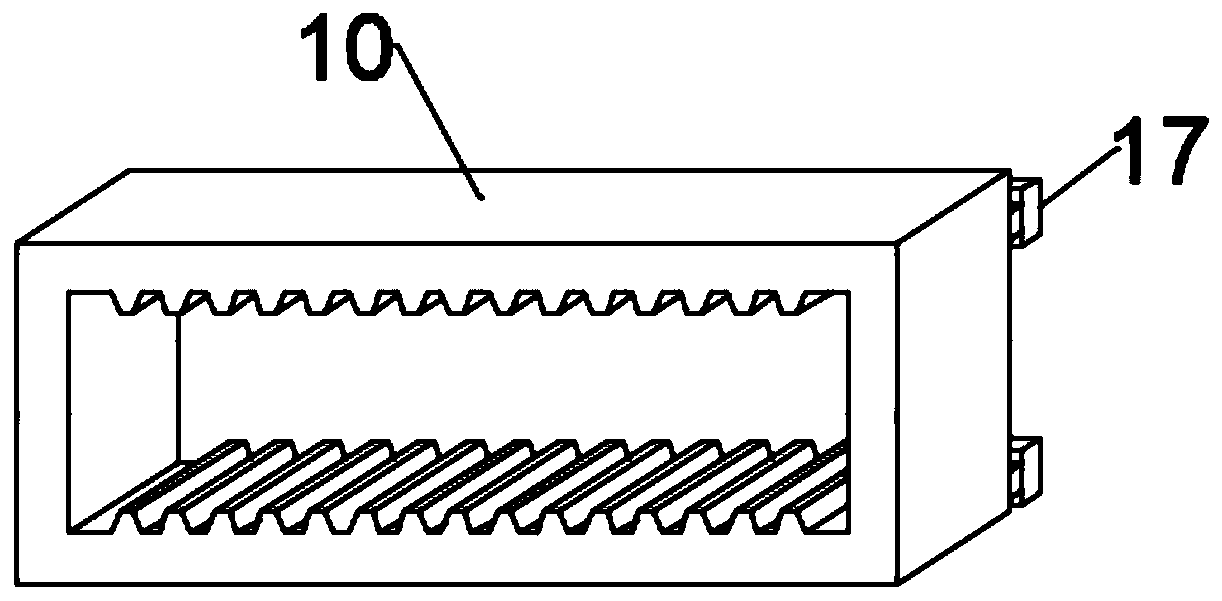

Handheld saw for garden maintenance

InactiveCN110463462AInnovative designAvoid fire situationsCuttersMotor driven pruning sawsEngineeringGuide tube

The invention relates to the technical field related to garden maintenance, in particular to a handheld saw for garden maintenance. The handheld saw for garden maintenance comprises a handle, a driving cavity and a saw blade; the handle is installed at one side end of the driving cavity; the saw blade is movably installed at the other side end of the driving cavity; one end of the saw blade is inserted into the driving cavity and connected to a driving component arranged in the driving cavity; the driving component drives the saw blade to reciprocate; a pumping mechanism is also arranged on the inner side of the driving cavity; the pumping mechanism is communicated with at least one spray head installed in the driving cavity and above the saw blade through a conduit, and is also communicated with a water tank installed in the driving cavity through another conduit. The handheld saw for garden maintenance is novel in design; water in the water tank is pumped to the spray head by the pumping mechanism during working, and is sprayed to the saw blade through the spray head, thereby preventing the situation of fire due to friction heating when the handheld saw is used in dry weather; the safety is high; meanwhile, the saw blade can be blown to achieve cooling operation when water is not put in the water tank, so that the practicability is strong.

Owner:阳丽萍

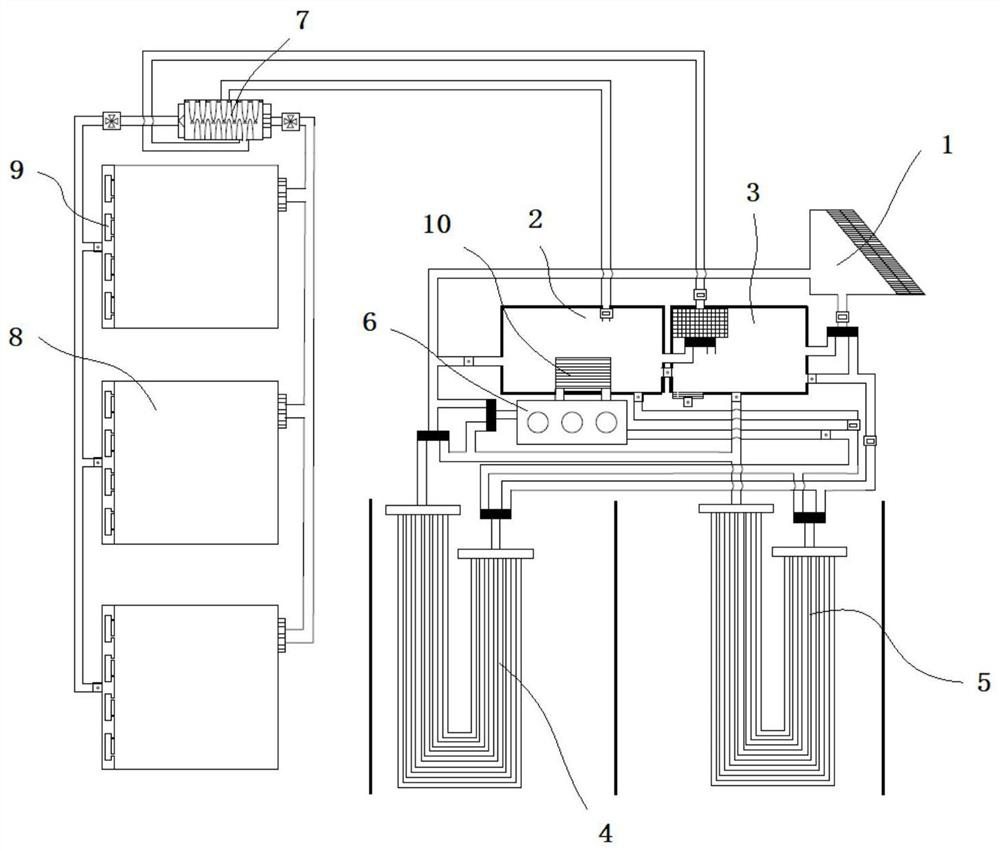

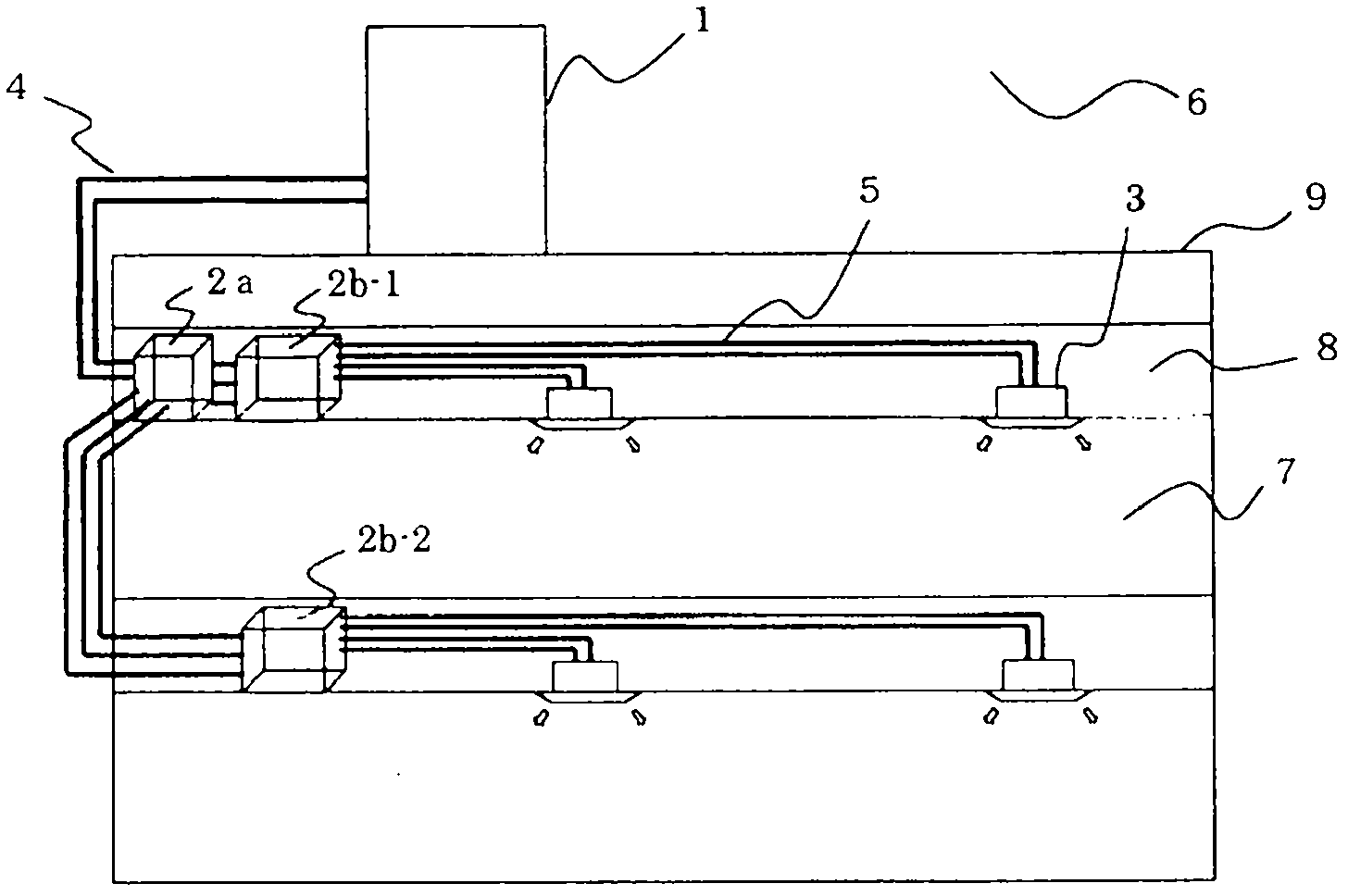

Air conditioner

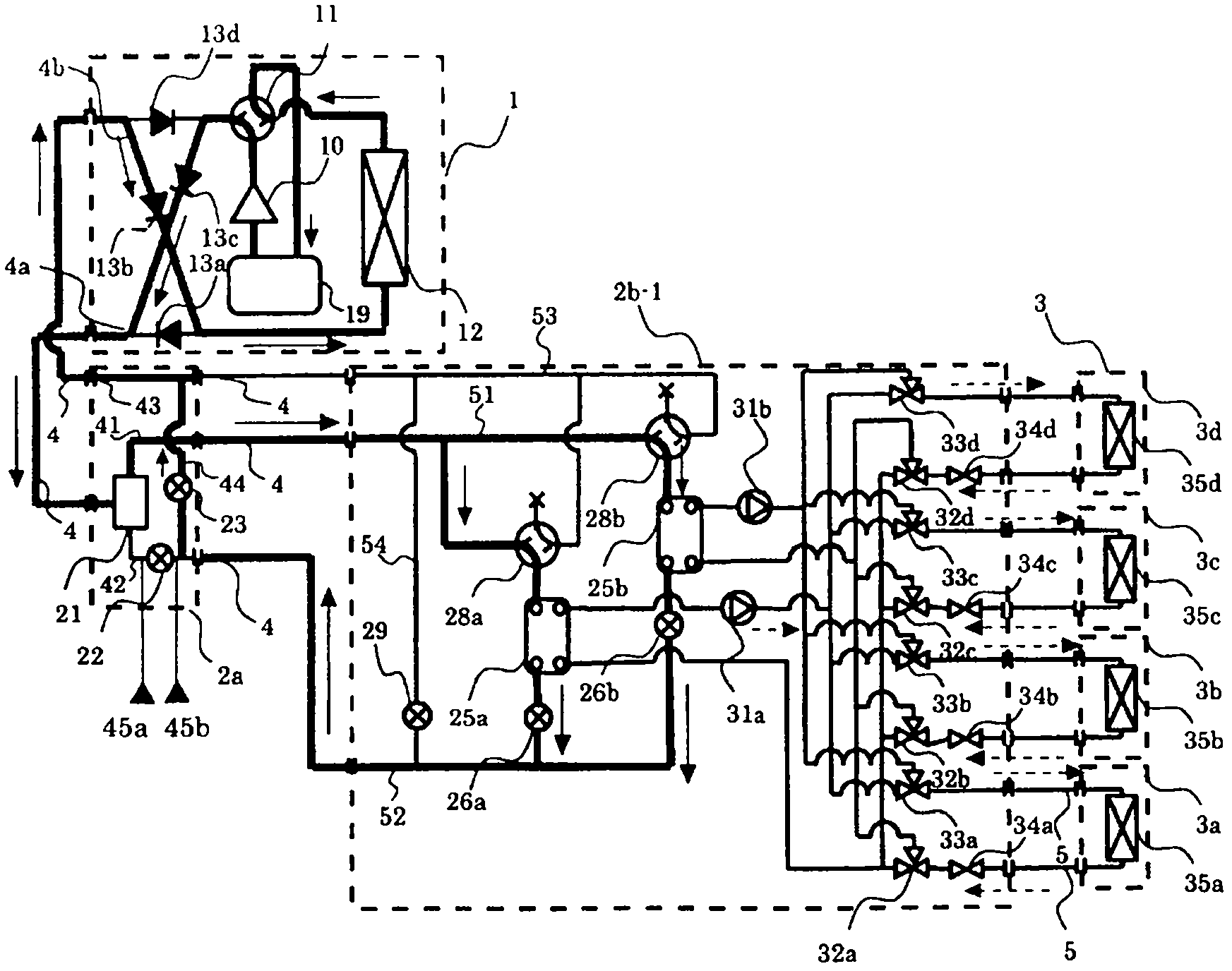

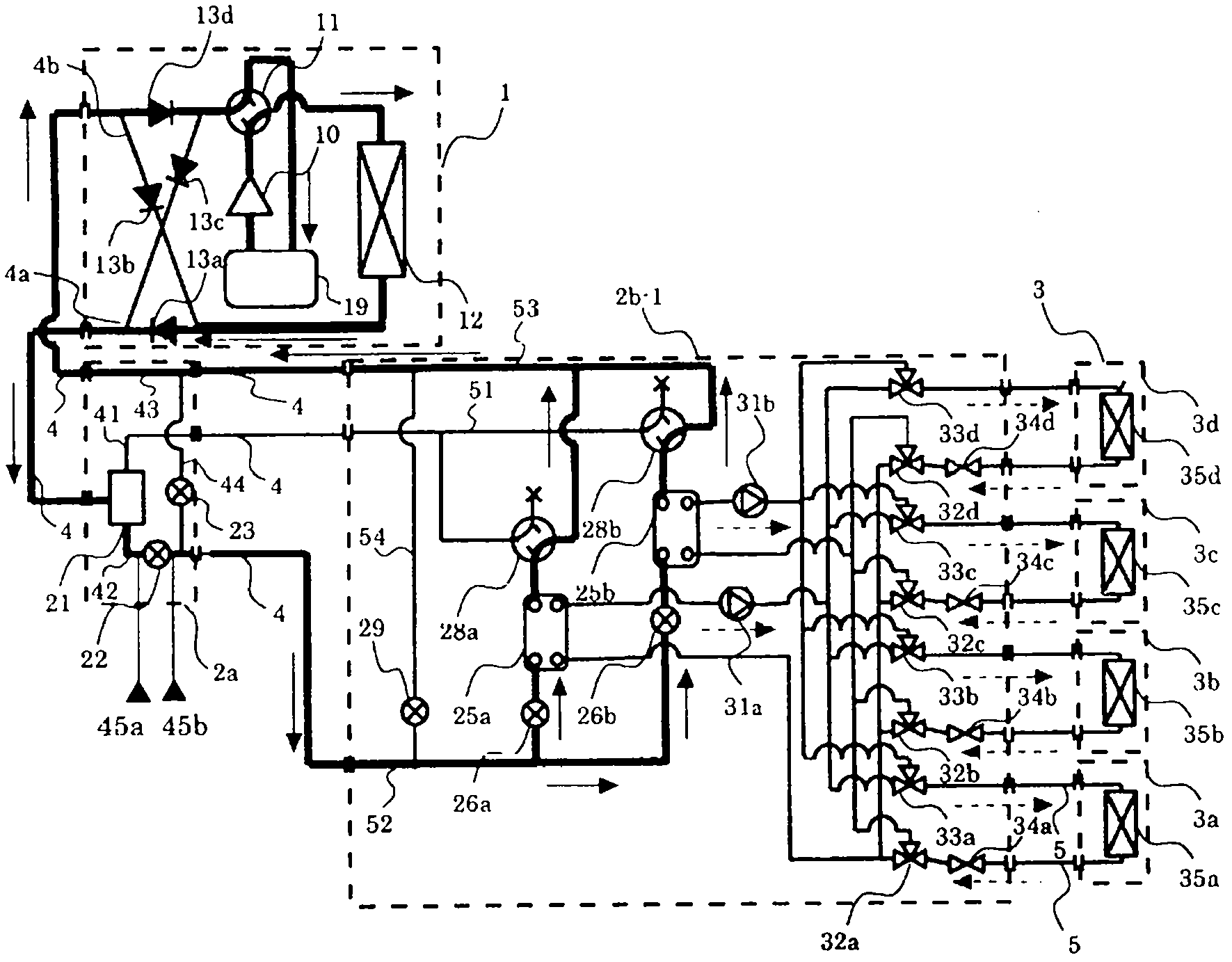

ActiveCN102597656BPrevent leakageShorten the conveying distanceCompression machines with non-reversible cycleCompression machines with reversible cycleProcess engineeringAir conditioning

The invention provides an air conditioner, comprising an outdoor unit (1), a plurality of indoor units (3) and a transfer unit, the outdoor unit (1) comprising a compressor (10) for compressing refrigerant and a compressor (10) between the refrigerant and the air A heat source side heat exchanger (12) for heat exchange; the plurality of indoor units (3) have a utilization side heat exchanger for circulating a heat medium and performing heat exchange between the heat medium and air; the transfer unit is between Between the outdoor unit (1) and the indoor unit (3), heat exchange is performed between the refrigerant delivered from the outdoor unit (1) and the heat medium flowing through the indoor unit. The main relay unit (2a) connected to the unit (1) and the sub relay unit (2a-1) connected to the main relay unit (2a) by 3 pipes are composed.

Owner:MITSUBISHI ELECTRIC CORP

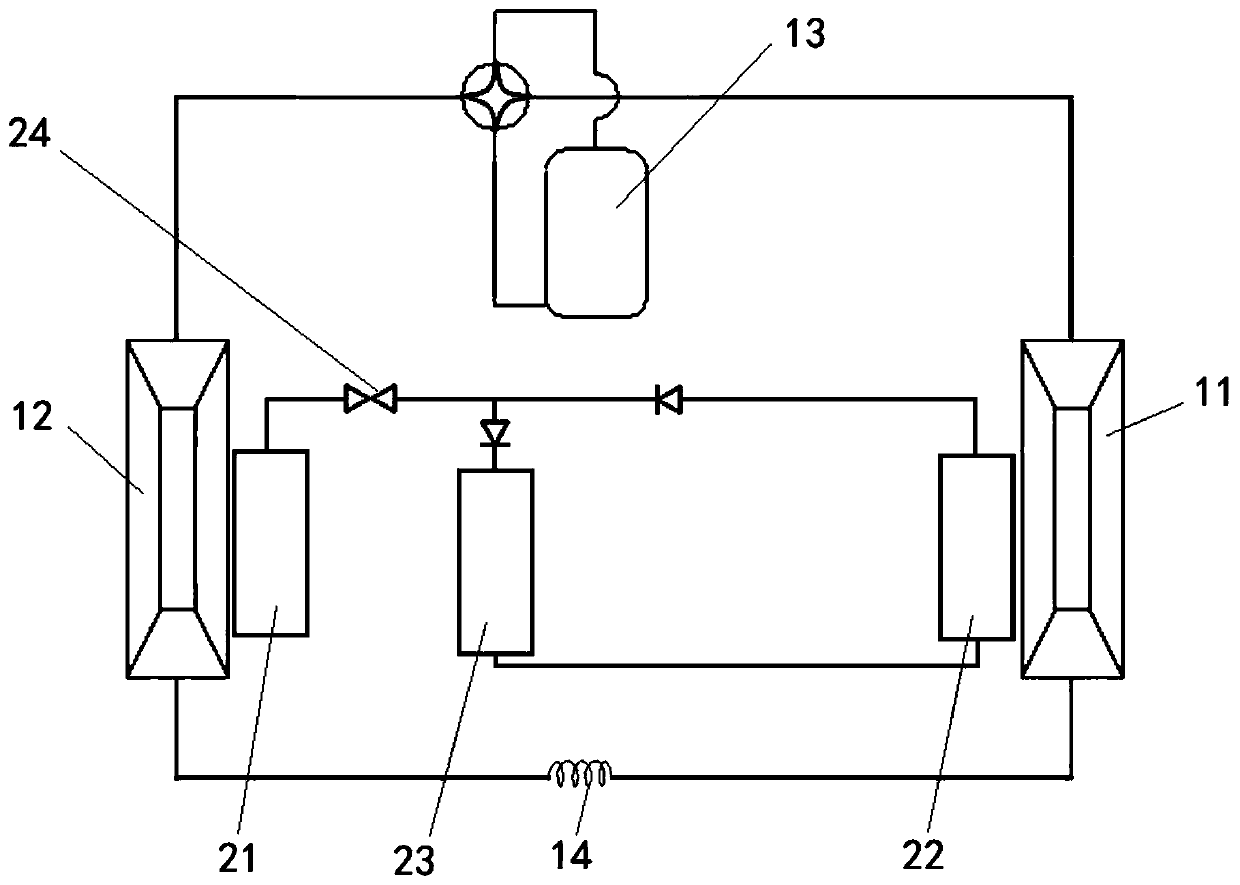

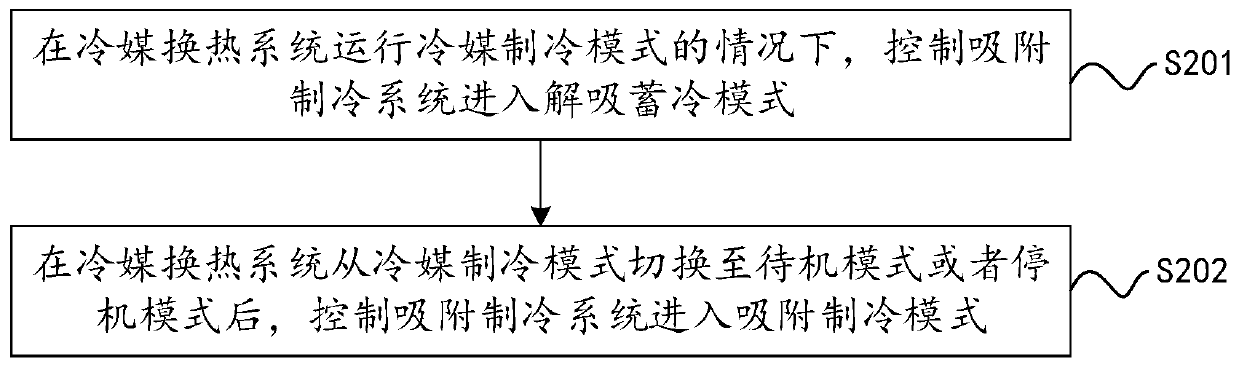

Control method and device for double-refrigeration type air conditioner and double-refrigeration type air conditioner

InactiveCN111442495ARealize cooling operationSimple structureMechanical apparatusFluid circulation arrangementAdsorption refrigerationThermal source

The invention relates to the technical field of intelligent refrigeration of air conditioners, and discloses a control method for a double-refrigeration type air conditioner. The control method includes the following steps that under the condition that a refrigerant heat-exchange system runs in arefrigerant refrigeration mode, an adsorption refrigeration system is controlled to be in a desorptioncold accumulation mode; and after the refrigerant heat-exchange system is switched from the refrigerant refrigeration mode to a standby mode or a shutdown mode, the adsorption refrigeration system iscontrolled to be in an adsorption refrigeration mode. According to the control method, the refrigerant heat-exchange system and the adsorption refrigeration system can be controlled to perform refrigeration alternately, and a heat source, used for performing desorption cold accumulation, of the adsorption refrigeration system is heat discharged by an outdoor heat exchanger when the refrigerant heat-exchange system performs refrigeration, so that the desorption process of adsorption refrigeration can be realized without arrangement of additional heat sources, and adsorption refrigeration can beperformed in an indoor environment under the conditions that the refrigerant heat-exchange system is shut down or is standby and the outdoor heat exchanger does not discharge heat. The invention further discloses a control device for the double-refrigeration type air conditioner and the double-refrigeration type air conditioner.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

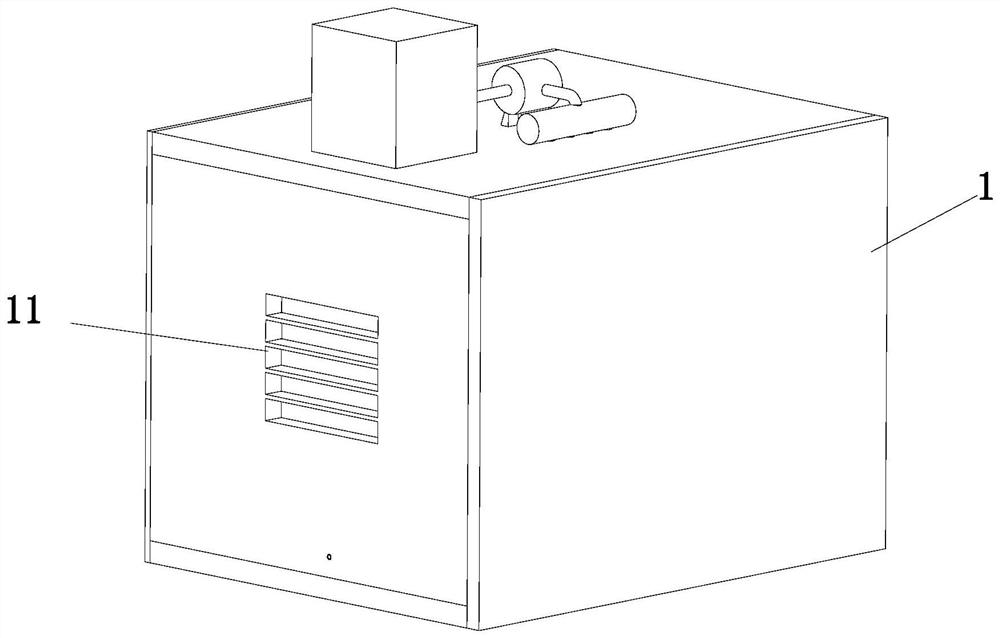

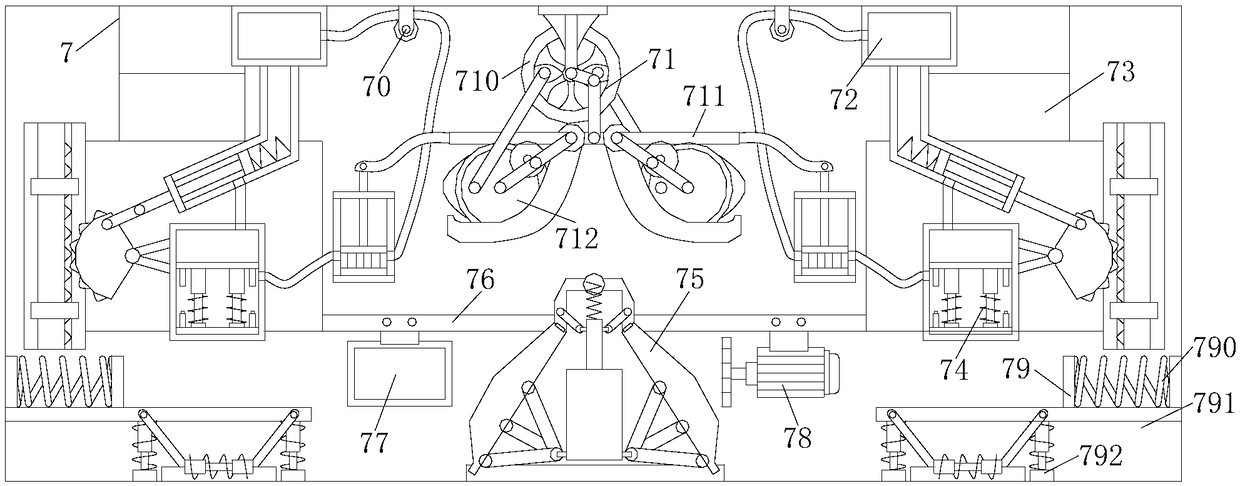

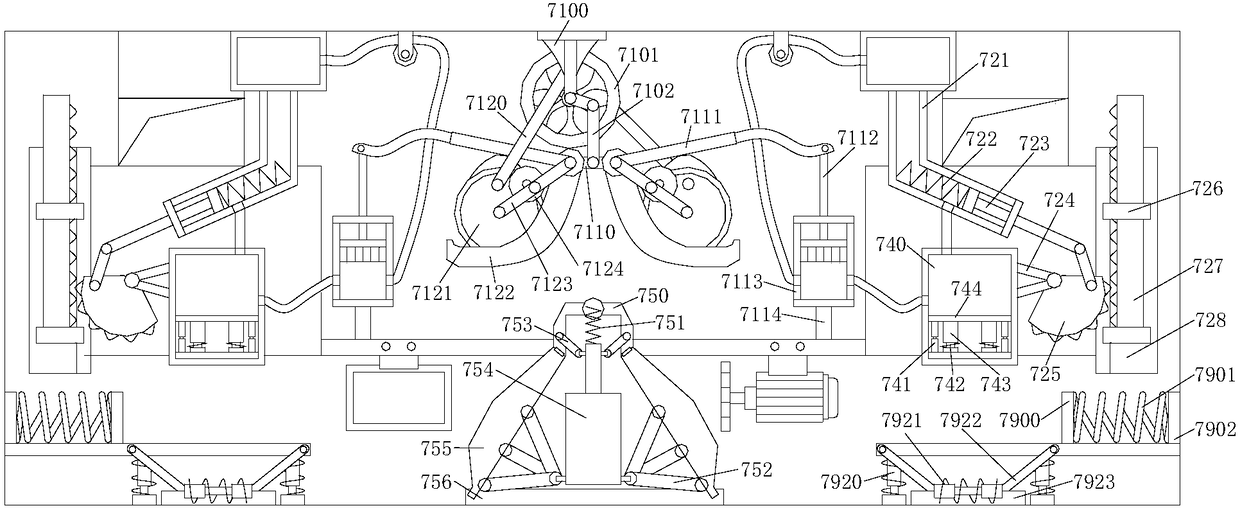

Anti-vibration power generation unit

InactiveCN108386272AReduce noiseAchieve fixationLiquid coolingNon-rotating vibration suppressionWater circulationEngineering

The invention discloses an anti-vibration power generation unit. The anti-vibration power generation unit structurally comprises a machine frame, a side material storage bin, a first heat dissipationdevice, an emergency controller, a front overhaul bin, a second heat dissipation device and a third heat dissipation device. The side material storage bin is embedded to the machine frame. The first heat dissipation device is locked to the side face of the machine frame, and the side material storage bin is adjacent to the first heat dissipation device and is located below the first heat dissipation device. The emergency controller is arranged on the front side face of the machine frame and located at the opposite end of the second heat dissipation device. The front overhaul bin is movably connected to the front side face of the machine frame. After a generator is installed, fixing and vibration reducing are achieved through a fixing device and a damping device; after running, heat dissipation is achieved through the first heat dissipation part and the second heat dissipation part; automatic opening and closing of a heat dissipation window are achieved through water circulation; and under the assisting of a freezer and a draught fan, repeated cooling of the equipment is achieved, then noise generated by the power generator unit is reduced through damping, and by means of synchronous heat dissipating and cooling, the service life of the equipment is effectively prolonged.

Owner:陈洪荣

Lychee fresh-keeping transport box

ActiveCN112009874BEasy to storeAvoid punctureContainers preventing decayShock-sensitive articlesAgricultural scienceLychee fruit

The invention discloses a litchi fresh-keeping transport box, which belongs to the technical field of litchi fresh-keeping transport and includes a transport box, a sulfur fumigation mechanism and two litchi storage mechanisms. The two litchi storage mechanisms have the same structure, and both of them include sliding Frame, buffer assembly and mounting plate, there are several lychee pockets on the mounting plate, there are several ventilation holes on the lychee pocket, the lychee pocket is made of flexible material, the cross section of the lychee pocket is pear-shaped, and the mounting plate corresponds to each The lychee pockets are all provided with a branch and leaf limit assembly, and the lychee pockets are provided with storage slots. The invention facilitates the preservation of bundled lychees with their branches and leaves, and avoids the phenomenon that the branches and leaves of lychees puncture the buffer air bag, and can effectively reduce the impact of lychees under the joint action of the buffer air bag, the upper shock-absorbing spring and the lower shock-absorbing spring. When there is a large vibration during transportation, the sulfur fumigation mechanism can automatically realize the sulfur fumigation of litchi, so that the breathing of litchi can be suppressed within a certain period of time.

Owner:SHANDONG BUSINESS INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com