Asphalt flue gas concentration device, system and method

A concentration device and asphalt flue gas technology, applied in separation methods, combustion methods, combined devices, etc., can solve the problems of large air volume flue gas damage to combustion-drying-dust removal effects, etc., to improve equipment utilization, save energy, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

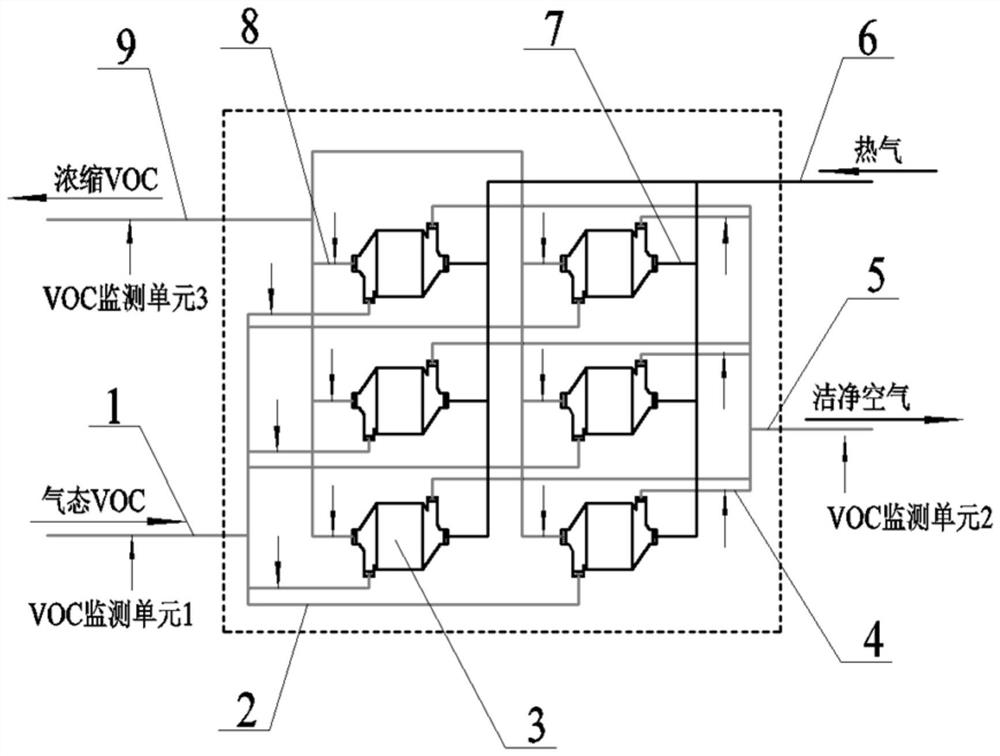

[0060] The asphalt fume concentration device provided by the invention is as figure 1 and figure 2 As shown, the device includes the first VOC input main pipeline (corresponding to VOC input main pipeline 1 in the figure), the second VOC input branch pipeline (corresponding to VOC input branch pipeline 2 in the figure), adsorption / desorption module 3, and output clean air Branch pipeline 4, output clean air main pipeline 5, desorption hot gas main pipeline 6, desorption hot gas branch pipeline 7, concentrated VOC branch pipeline 8, concentrated VOC main pipeline 9 and control system, etc. The control system is mainly responsible for adsorption and desorption , Cooling and other operations automation control logic realization.

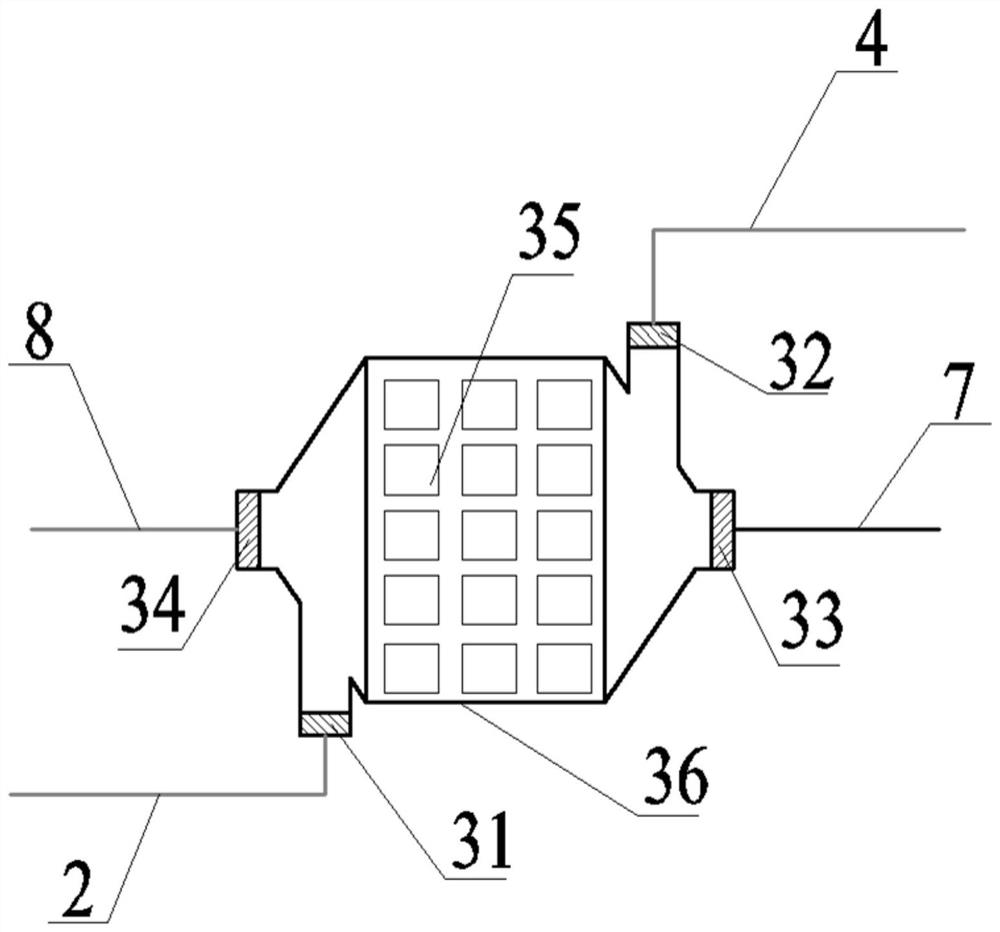

[0061] Adsorption / desorption module 3 is the core device of the concentration system, mainly composed of VOC input valve 31, clean air output valve 32, desorption hot gas input valve 33, concentrated VOC output valve 34, adsorption material 35 and box...

Embodiment 2

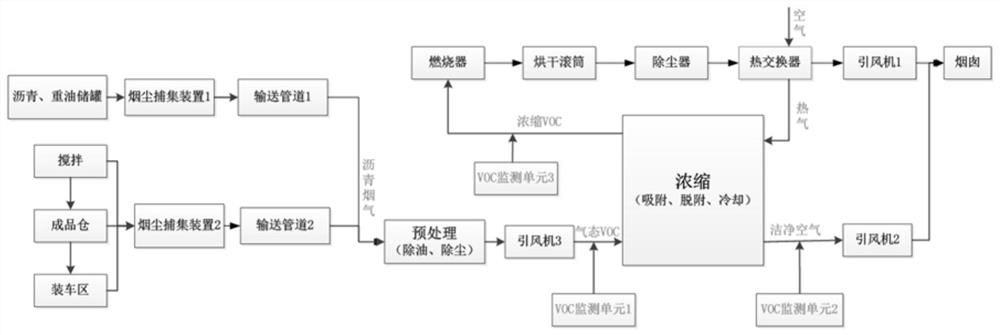

[0069] Such as Figure 1 to Figure 4 As shown, this embodiment provides an asphalt fume concentration system, which includes the asphalt fume concentration device in Embodiment 1. The system mainly includes the first soot trapping device (corresponding to soot trapping device 1 in the figure), the second soot trapping device (corresponding to soot trapping device 2 in the figure), conveying pipeline 1, conveying pipeline 2, pretreatment system, The induced draft fan 3, the induced draft fan 2, the heat exchanger and the asphalt flue gas concentrator in embodiment 1, and the original burner, drying drum, dust collector, induced draft fan 1 and chimney of the asphalt mixing station, the heat exchanger is The newly added device between the dust collector and the induced draft fan 1 in the original dust removal system can make full use of the residual temperature of the dust removal flue gas to provide desorption hot gas for the concentration system. The heat exchanger has a self-...

Embodiment 3

[0076] Such as Figure 1 to Figure 5 As shown, this embodiment provides a method for concentrating bitumen flue gas, which is realized based on the concentration system in Embodiment 2, and specifically includes the following process.

[0077] Collect asphalt fumes escaped during the heating process of asphalt and heavy oil storage tanks, and transport the recovered asphalt fumes to the pretreatment system through the delivery pipeline 1 for pretreatment. The second smoke and dust collection device is responsible for collecting the asphalt fumes escaped during the mixing, storage and discharging of asphalt mixture, and transporting the recovered asphalt fumes to the pretreatment system through the conveying pipeline 2 for pretreatment.

[0078] The pretreatment system includes multi-level pretreatment measures. The asphalt flue gas entering the pretreatment system is firstly treated by a first-level pretreatment-oil pan centrifugal demisting treatment to remove most of the lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com