Cement cooling device

A cooling device and cement technology, which is applied in the direction of fixing conduit components, heat exchanger types, lighting and heating equipment, etc., can solve the problems of cement agglomeration and cement powder being damp, and achieve the effect of speeding up the delivery and reducing the cooling time of stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

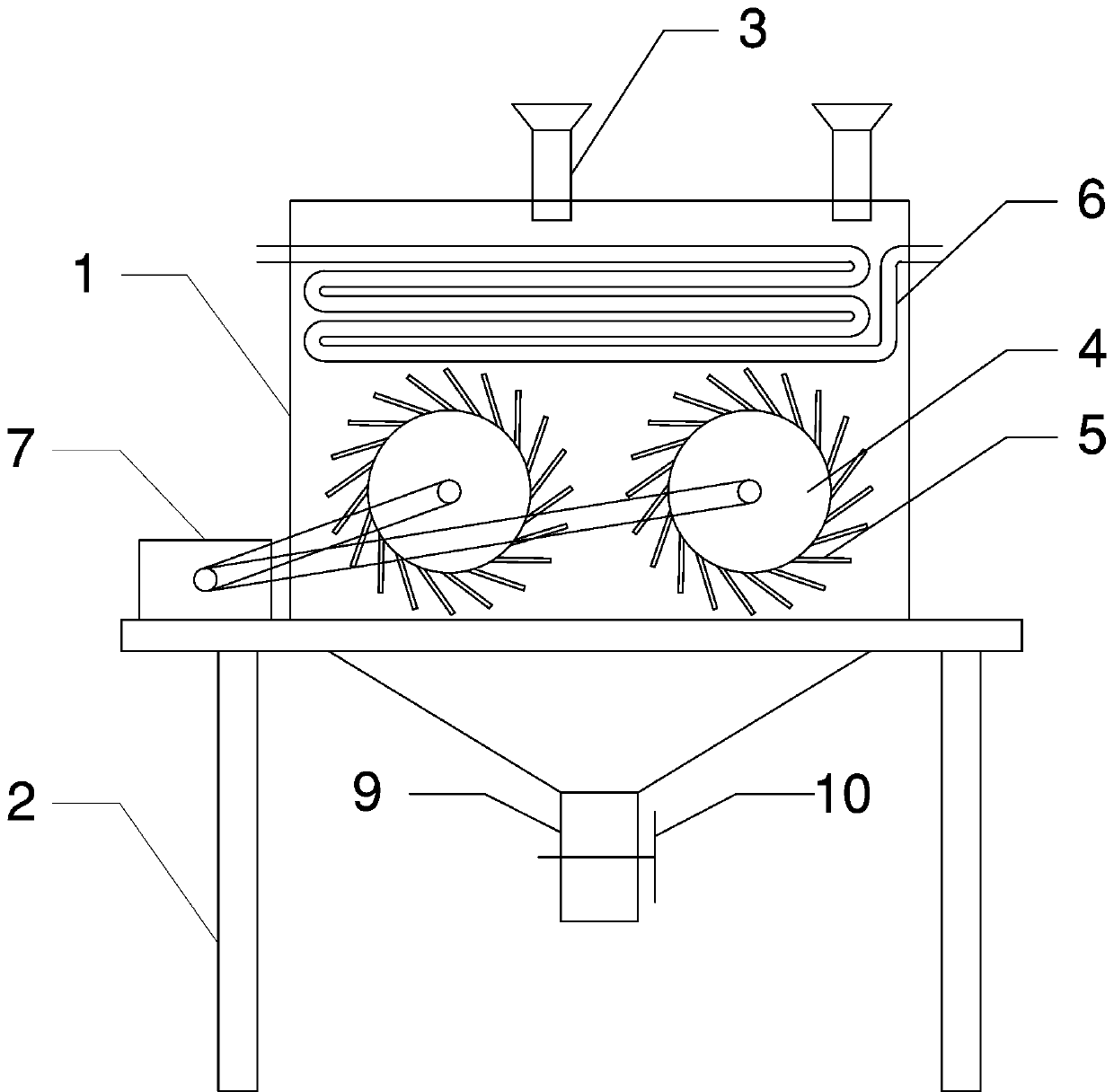

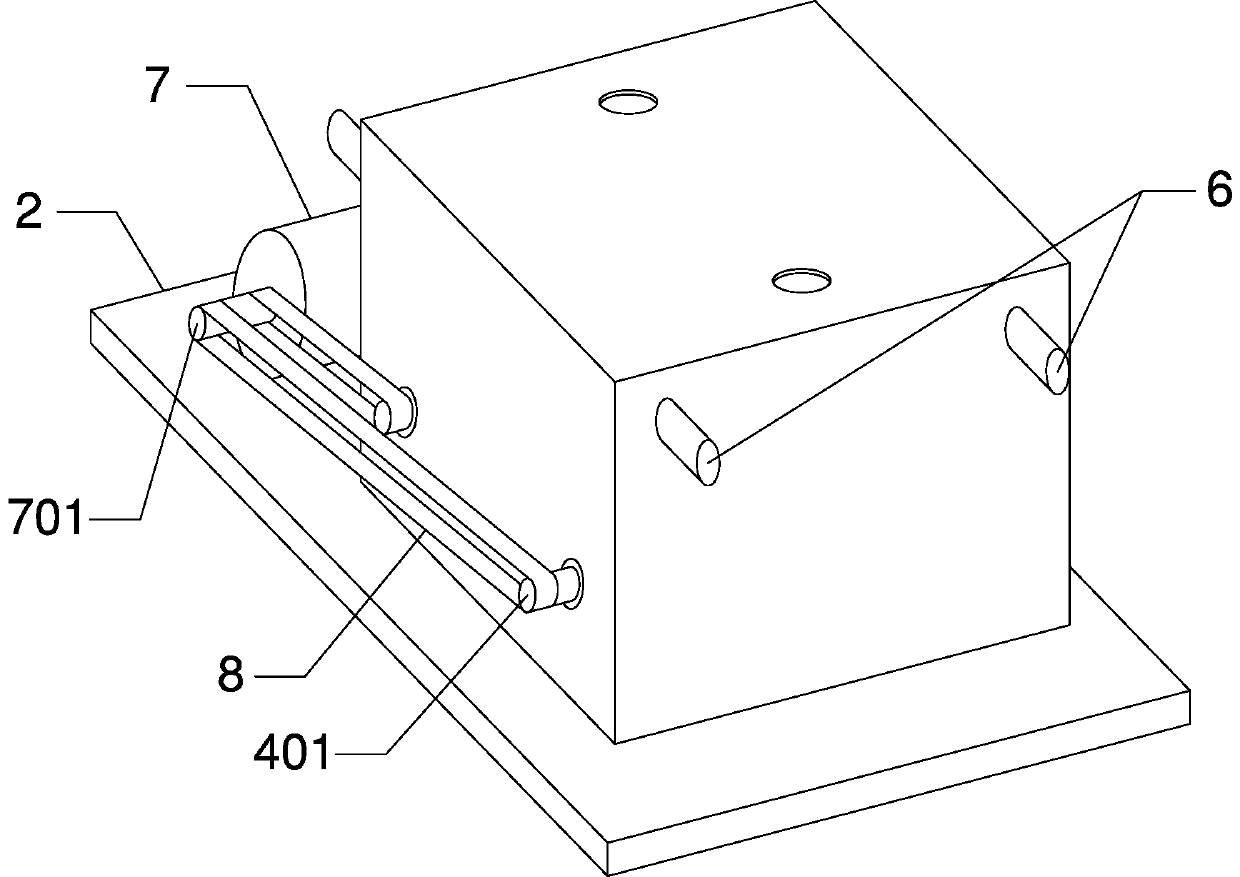

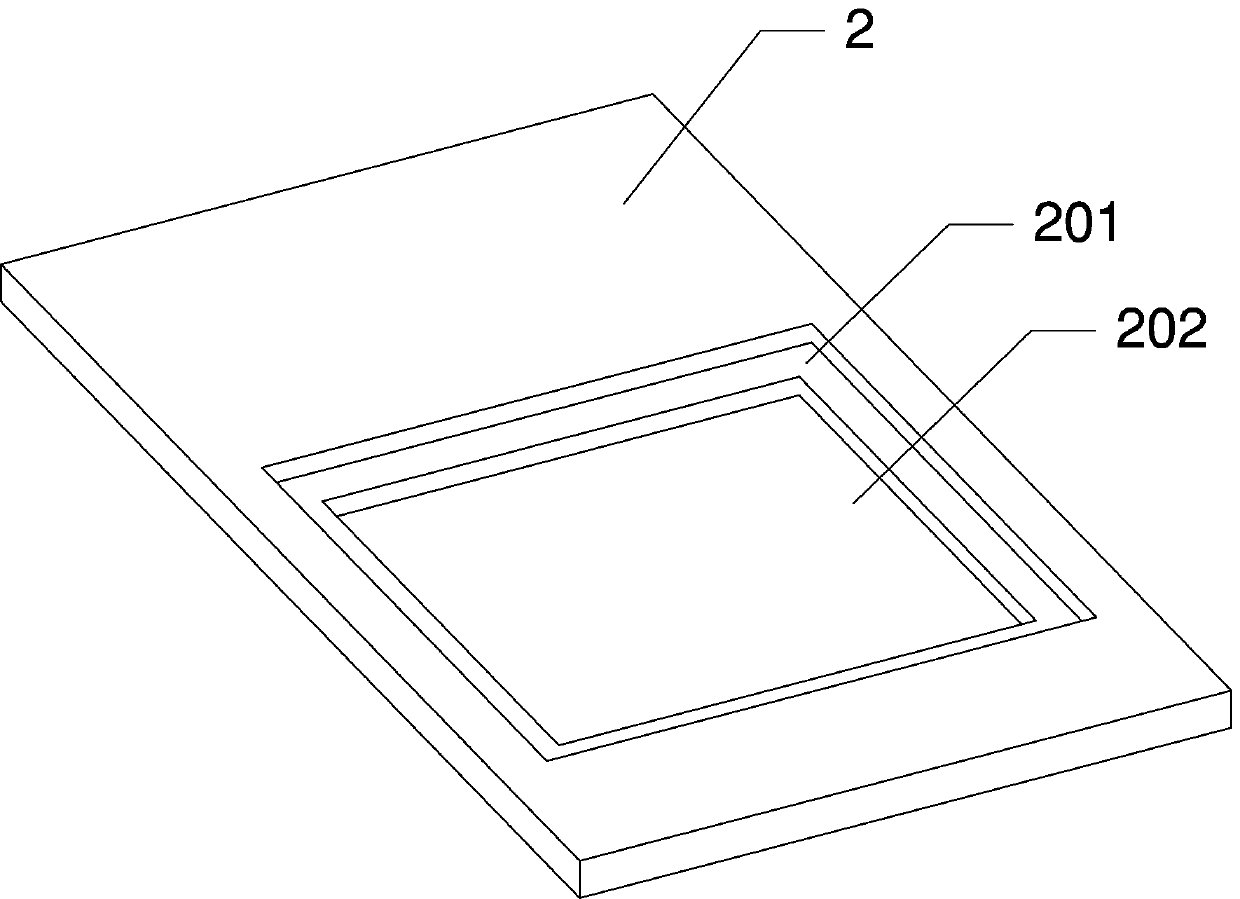

[0020] Such as figure 1 Among them, a cement cooling device, including a drying chamber 1, the drying chamber 1 is fixedly arranged on the bracket 2, the drying chamber 1 is provided with a drum 4, the drum rotating shaft 401 of the drum 4 is arranged horizontally, and the drum 4 The top is provided with a feed hopper 3, and the downward extension line of the feeding end of the feed hopper 3 is tangent to the drum 4, and a plurality of rubber belts 5 are arranged on the outer wall of the drum 4, and one end of the rubber belt 5 is fixed to the outer wall of the drum 4 connect.

[0021] In a preferred solution, one end of the drum rotating shaft 401 passes through the side wall of the drying chamber 1 and extends to the outside of the drying chamber 1, and the drive motor 7 is arranged on the support, and the motor rotating shaft 701 of the driving motor 7 is connected to the rotating shaft 701. The drum rotating shafts 401 of the drum 4 are connected by a transmission belt 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com