Wind conveying spray gun capable of achieving dust suppression and haze removal

A technology of dust suppression and haze removal and air delivery, which is applied in the field of air delivery spray guns, urban cooling operations, and large-area spray dust removal and haze removal. , increase or decrease the number of nozzles, and enhance the effect of atomization range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

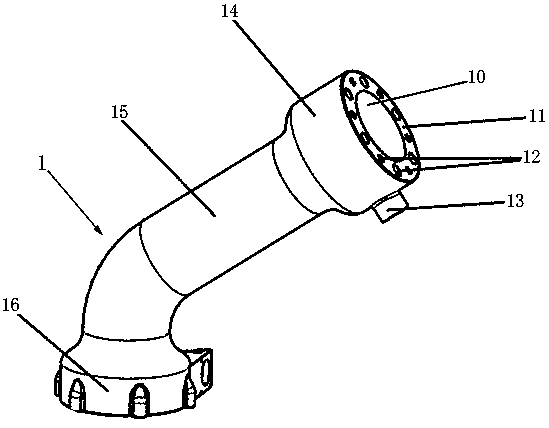

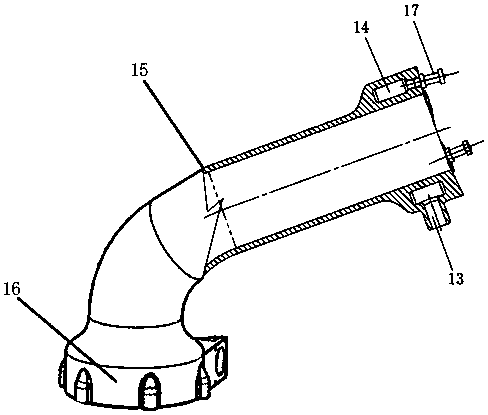

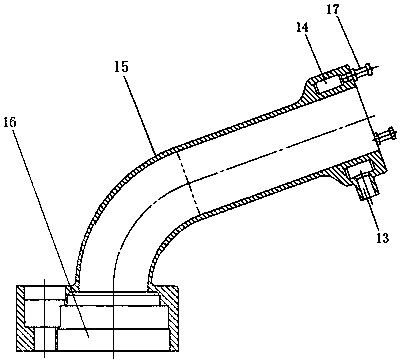

[0036] This example figure 1 with figure 2 Shown, spray gun 1 comprises air cylinder 15, and air cylinder 15 is an elbow, and the lower end of air cylinder 15 is swivel joint 16, and the top of air cylinder 15 is air outlet 10, and spray device is housed at air outlet, and water inlet pipe 13 Connect to the spray unit.

[0037] The spraying device receives the pressurized water entering from the water inlet pipe 13, and sprays water mist. The high-speed airflow of the air outlet 10 of the fan cylinder is in the same direction as the sprayed water mist, forming the superposition of two energies of wind energy and sprayed water energy, which overcomes the problem of water mist. The obstruction of the fog to the airflow, the blowing distance of the water mist increases, or the power of the fan is reduced accordingly.

[0038] Because the air cylinder 15 is an elbow, the rotary joint 16 can realize the spray device installed at the air outlet of the air cylinder to rotate aroun...

Embodiment 2

[0045] Such as Figure 4 with Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that: the water supply ring 14 is arranged on the inner ring of the air cylinder 15, and the water supply ring 15 is composed of the inner wall of the air cylinder, the reducing pipe 19 and the top sealing plate 11. The spraying device adopts the variable diameter pipe 19 in the air outlet 10, which can improve the wind speed, increase the kinetic energy, and make the water mist spray farther.

[0046] Image 6 with Figure 7 It is a further improvement to the present invention: the edge of the air outlet 10 is evenly distributed with silencing serrations 20, and the silencing serrations 20 are used to reduce the eddy current generated by the air outlet and reduce the noise at the outlet of the spray gun. In this embodiment, three atomizing nozzles 17 are evenly distributed along the circumference of the top sealing plate 11 .

Embodiment 3

[0048] Such as Figure 8 with Figure 9As shown, the difference between this embodiment and Embodiment 1 is that the spray device includes an atomizing nozzle and a nozzle connecting seat 18, the center of the air outlet 10 is provided with a nozzle connecting seat 18, and the atomizing nozzle 17 is installed on the nozzle connecting seat 18, and the air duct The front end side wall of 15 is equipped with the water inlet guide pipe 13 that connects flexible pipe, and water inlet guide pipe 13 is communicated with nozzle connection seat 18 by internal aperture. The high-pressure water directly enters the atomizing nozzle 17 installed in the center of the air outlet through the water inlet pipe 13 .

[0049] The inner tube of the air outlet 10 is a diameter reducing pipe 19, which is conducive to improving the wind speed, increasing kinetic energy, and making the water mist spray farther. The edge of the air outlet 10 can also be provided with sound-absorbing serrations to red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com