Wire drawing mould manufacturing method capable of implementing water cooling treatment

A manufacturing method and water-cooling treatment technology, applied in the field of mold manufacturing, can solve problems such as poor heat dissipation of wire drawing dies, affecting the service life of mold cores, and high brittleness of forming wires, so as to improve processing quality and efficiency, easy implementation, and connection performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

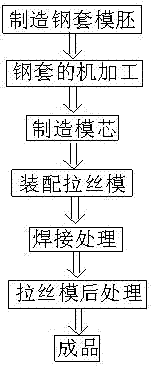

Image

Examples

Embodiment 1

[0018] The specific preparation process of the manufacturing method that can implement the water-cooling treatment wire drawing die that the present invention mentions is as follows:

[0019] a) Manufacture the steel sleeve mold base, the material of the steel sleeve is stainless steel, and the steel type is 1Cr13; the forming process of the steel sleeve mold base is investment casting, and the spiral groove structure on the surface of the inner cavity of the steel sleeve is made by this casting process ; After casting, annealing treatment is required, the heating temperature is controlled at 800°C-820°C, and the heat is kept for 1.5 hours and then slowly cooled in the air;

[0020] b) Machining of the steel sleeve, which includes grinding of the inner cavity of the steel sleeve, drilling of the water inlet and outlet holes on the left and right sides, and grinding and polishing of the outer circle; among them, the inner cavity of the steel sleeve The grinding process of the b...

Embodiment 2

[0026] The specific preparation process of the manufacturing method that can implement the water-cooling treatment wire drawing die that the present invention mentions is as follows:

[0027] a) Manufacture the steel sleeve mold base, the material of the steel sleeve is stainless steel, and the steel type is 2Cr13; the forming process of the steel sleeve mold base is investment casting, and the spiral groove structure on the surface of the inner cavity of the steel sleeve is made by this casting process ; After casting, annealing treatment is required, the heating temperature is controlled at 820°C-840°C, and the temperature is kept for 1.5 hours and then slowly cooled in the air;

[0028] b) Machining of the steel sleeve, which includes grinding of the inner cavity of the steel sleeve, drilling of the water inlet and outlet holes on the left and right sides, and grinding and polishing of the outer circle; among them, the inner cavity of the steel sleeve The grinding process o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com