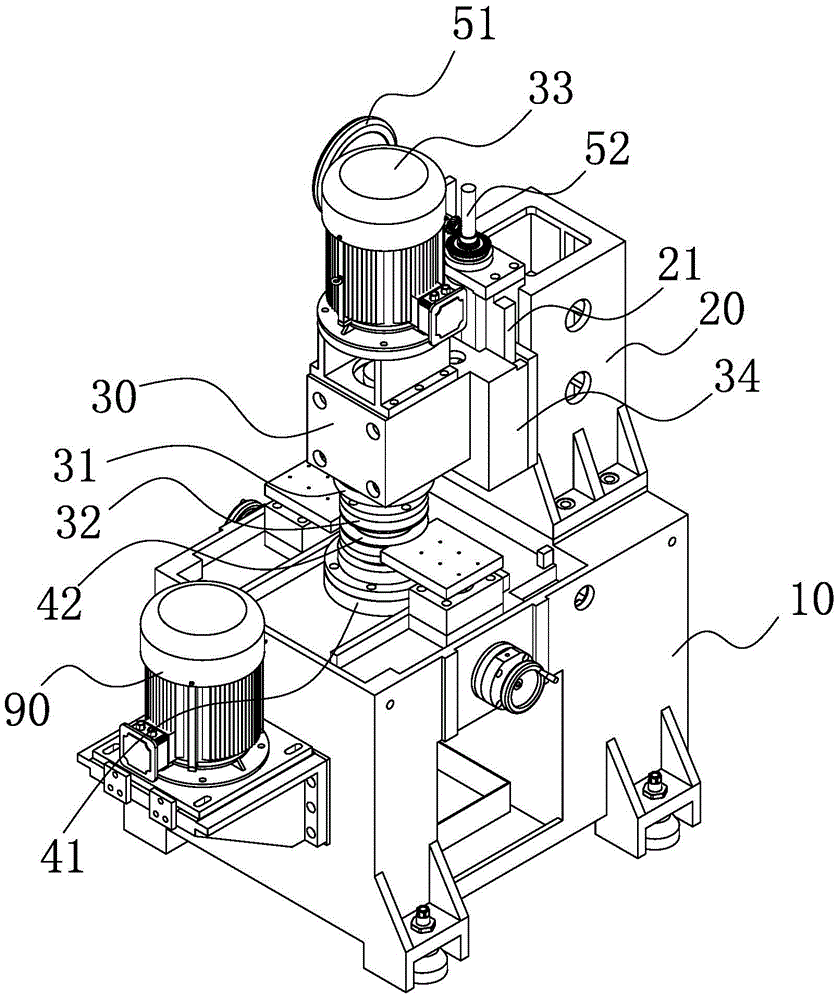

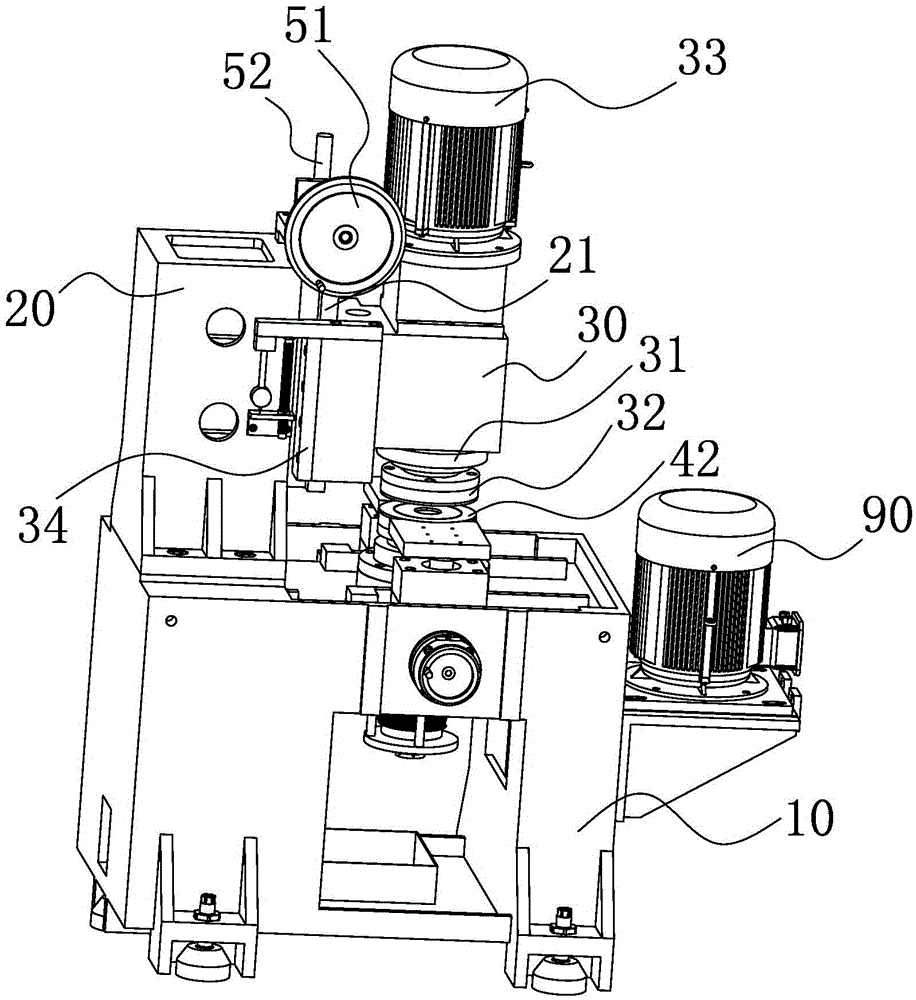

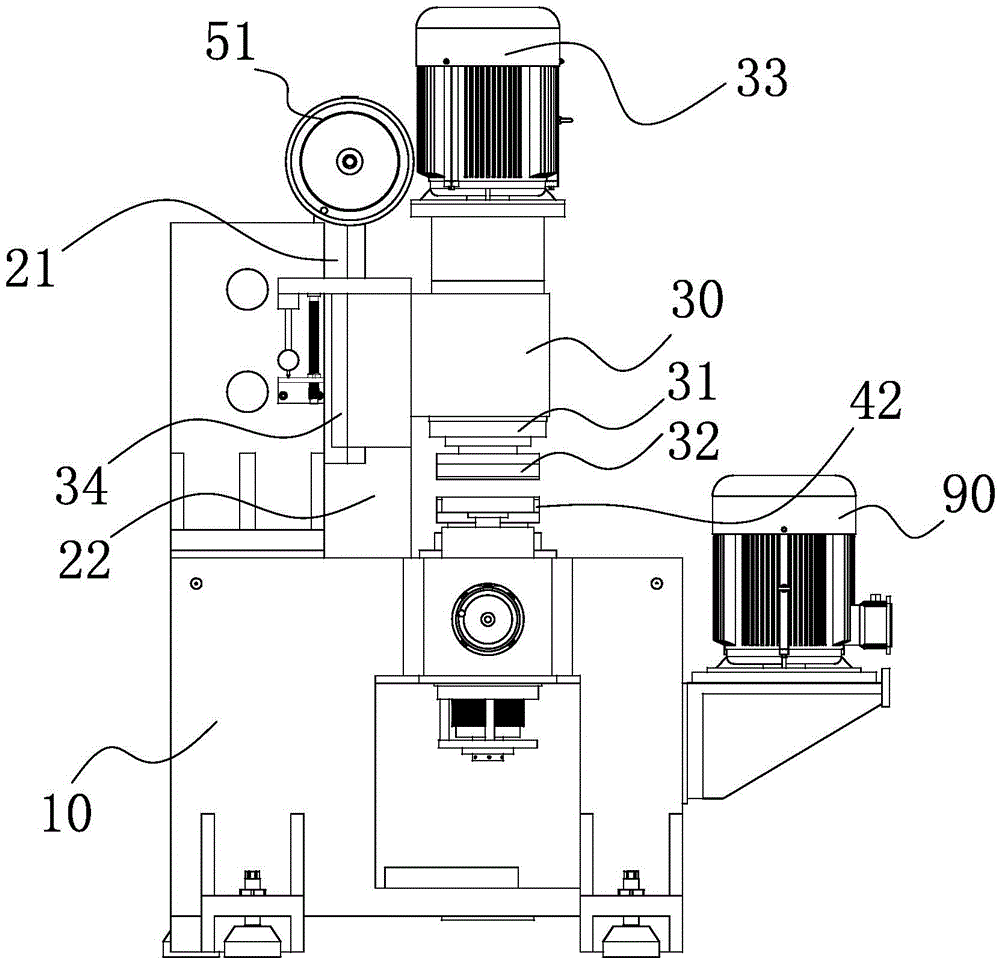

Cooling system of vertical end surface grinding machine

A technology of face grinding machine and cooling system, which is applied in the direction of grinding machine parts, grinding machine, grinding machine bed, etc., can solve the problems of not meeting the development needs of high-speed chemical industry, reducing the reliability of equipment work, and unreasonable structure design of grinding machines. , to achieve the effect of improving product forming effect, good cooling effect, and realizing cooling operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0028] The invention protects a cooling system of a vertical end surface grinder, which is suitable for processing the smoothness and thickness of both sides of thin slice products.

[0029] The structure design of the existing grinding machine is unreasonable. The coolant is directly sent from the external water tank to the water spray pipe on the side of the grinding head, and is directly sprayed to the grinding head through the water spray pipe. It is easy to splash and cannot be recovered during work, resulting in cooling effect. Poor, the reliability of the overall equipment is reduced, which does not meet the development needs of the high-speed chemical industry. Therefore, it is necessary to design a more reasonable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com