Cooking utensil

A technology of cooking utensils and cooking utensils, which is applied in the direction of steam cooking utensils, cooking utensils, cooking utensils/covers, etc., and can solve the problems of low heat utilization rate and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

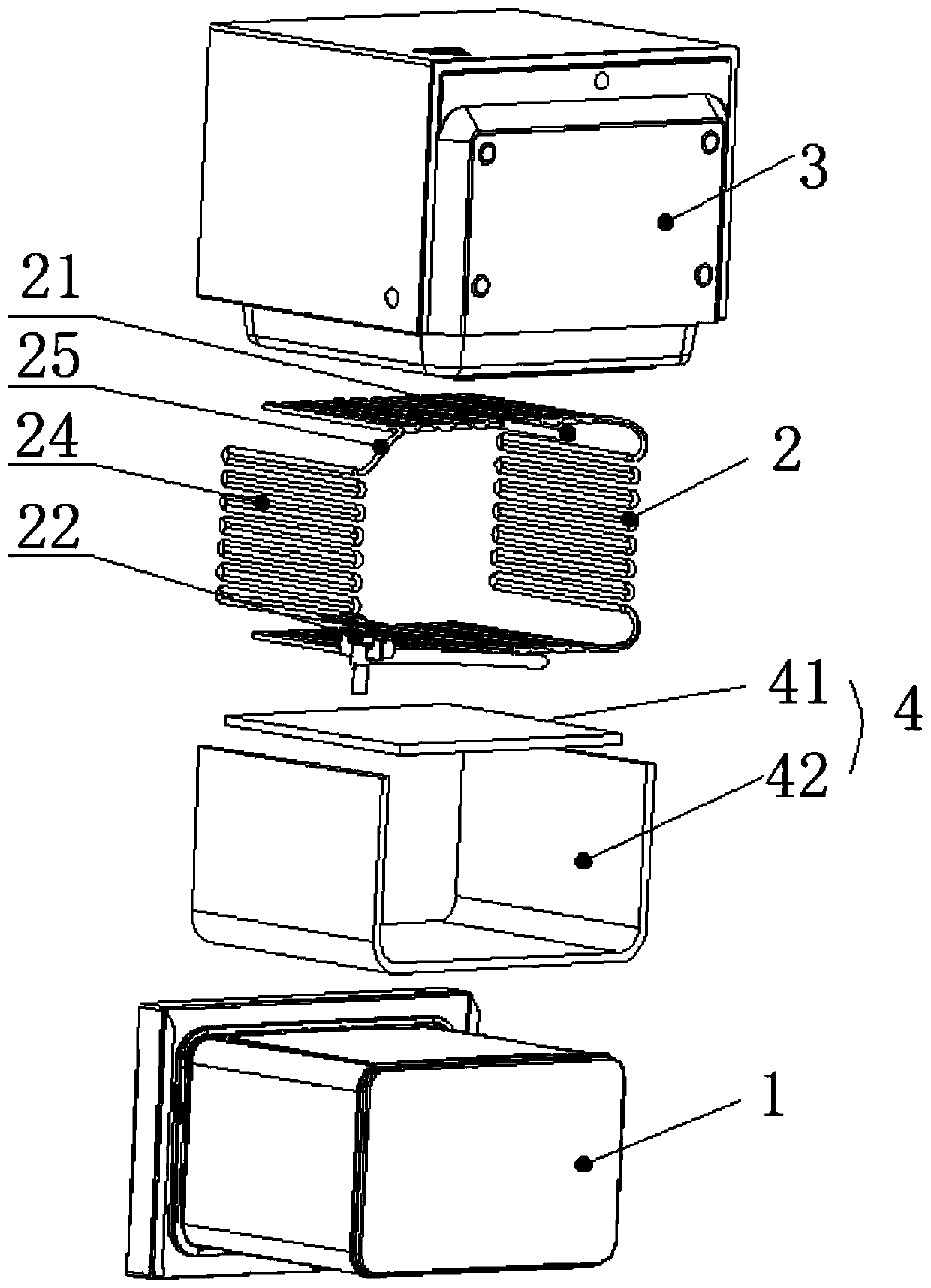

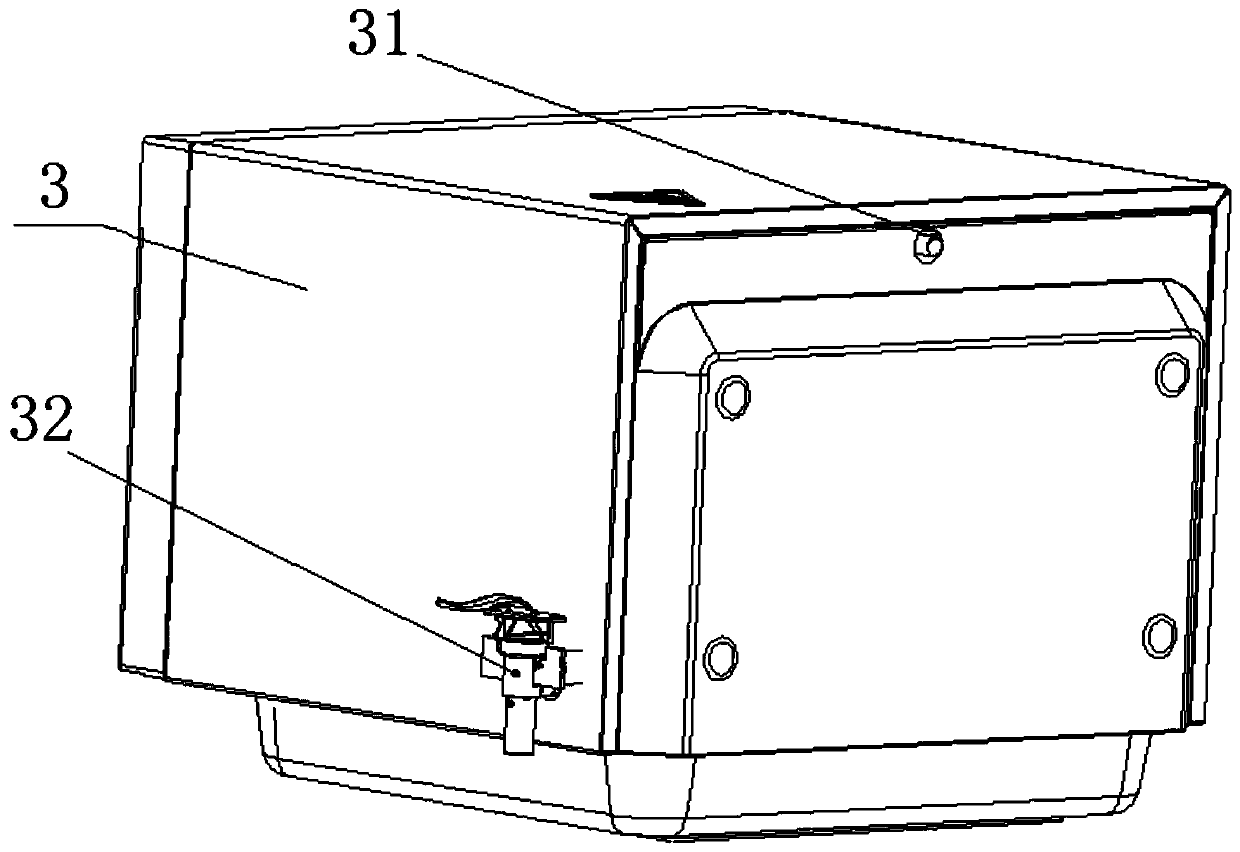

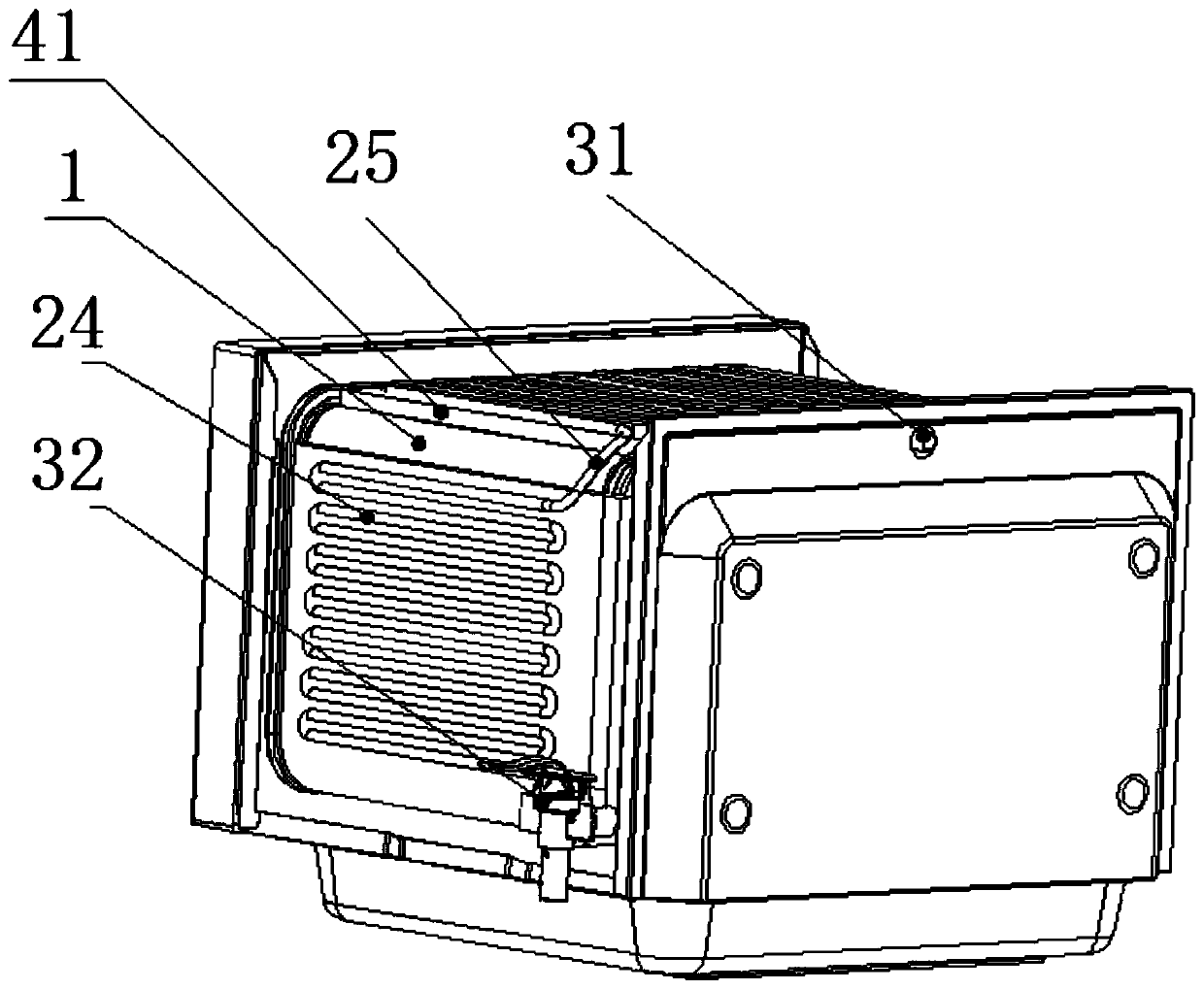

[0043] This embodiment provides a cooking utensil, which can be an oven, a steamer, or an integrated steaming and baking machine, such as Figure 1-Figure 8 shown, including:

[0044] The furnace 1 is provided with a space suitable for placing ingredients inside, and the furnace 1 itself is made of metal material, such as stainless steel. An opening is provided on the furnace 1, and a door body suitable for closing or opening the opening is provided on the opening. A sealing ring is provided on the corresponding part of the door body and the opening. 1, so as to avoid heat, etc. from escaping through the opening;

[0045]The waterway plate 2 is arranged on the outer wall of the furnace 1, and the waterway plate 2 is provided with a first water inlet 21 and a first water outlet 22. In this embodiment, the first water inlet 21 is suitable for receiving external water sources , the cooling water entering through the first water inlet 21 flows through the water channel plate 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com