Energy-absorbing protection structure of ceramic hollow buoyancy ball and preparation method thereof

A technology for protecting structures and buoyancy balls, which is applied to hollow objects, underwater operation equipment, and other household appliances, etc., to achieve the effect of simple overall structure and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

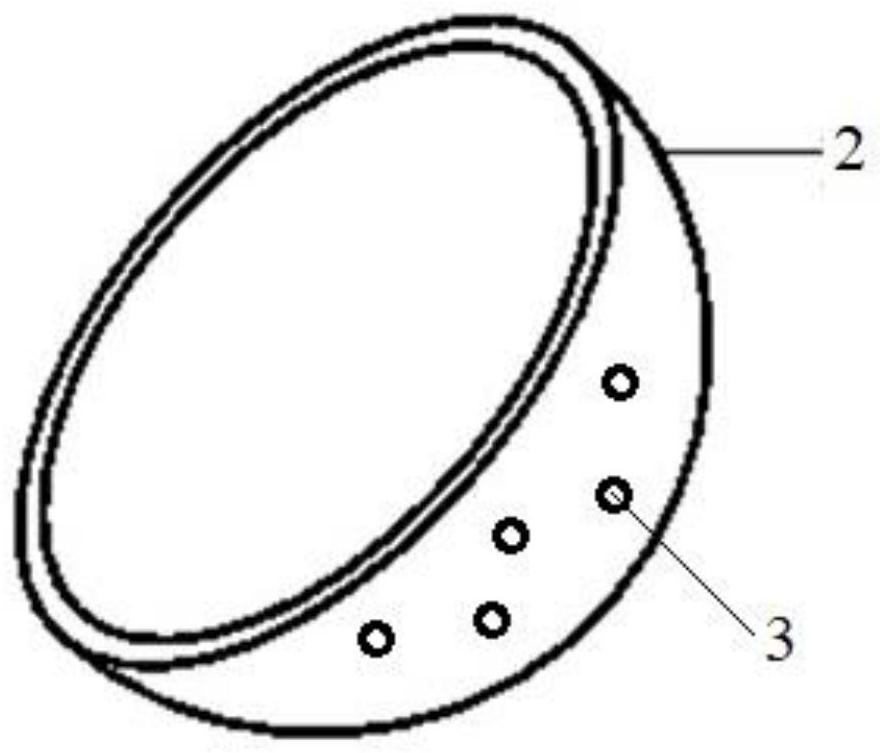

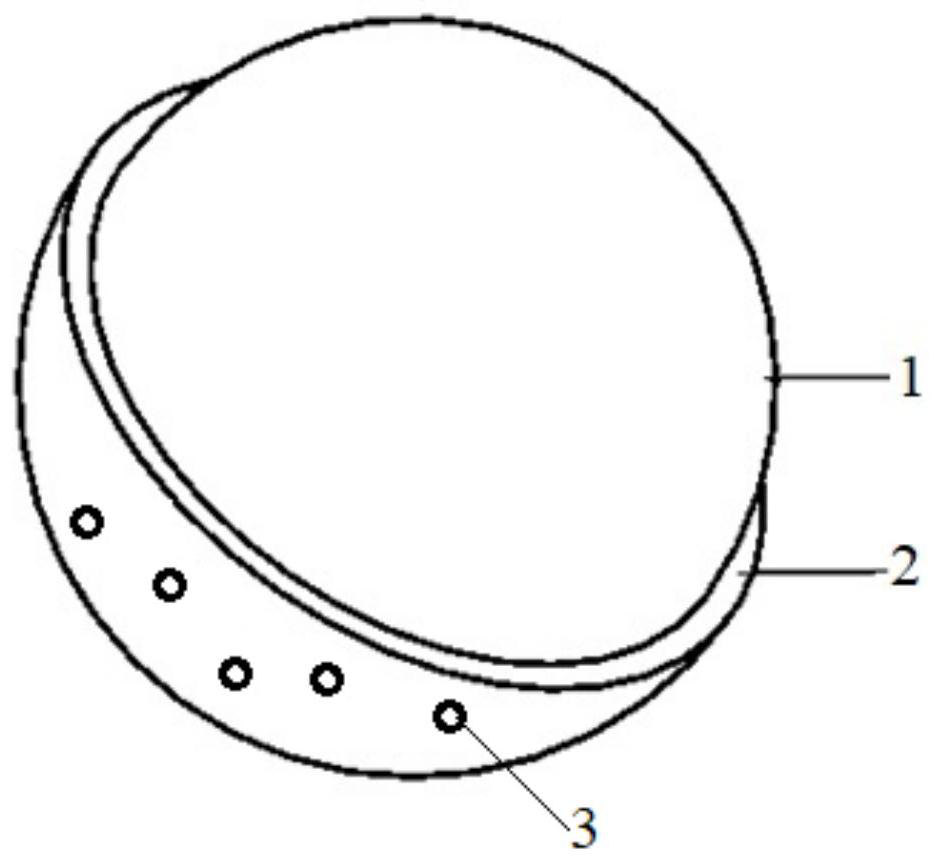

[0043] combine figure 1 and figure 2 As shown, the energy-absorbing protection structure of the ceramic hollow buoyancy ball according to the embodiment of the present invention includes a spherical shell, which is arranged on the surface of the ceramic hollow buoyancy ball 1. The spherical shell in this embodiment includes a first hemispherical shell 2 and a second hemispherical shell 2. There are two hemispherical shells, the first hemispherical shell 2 has the same structure as the second hemispherical shell, and there are water through holes 3 on it.

[0044] The thickness of the first hemispherical shell 2 and the second hemispherical shell are both 10 mm, and the thickness can be designed as long as it does not affect the buoyancy of the ceramic hollow buoyancy ball. The first hemispherical shell 2 and the second hemispherical shell are combined through a threaded structure, and in other embodiments, a riveting or locking component can also be used for combination.

[0...

Embodiment 2

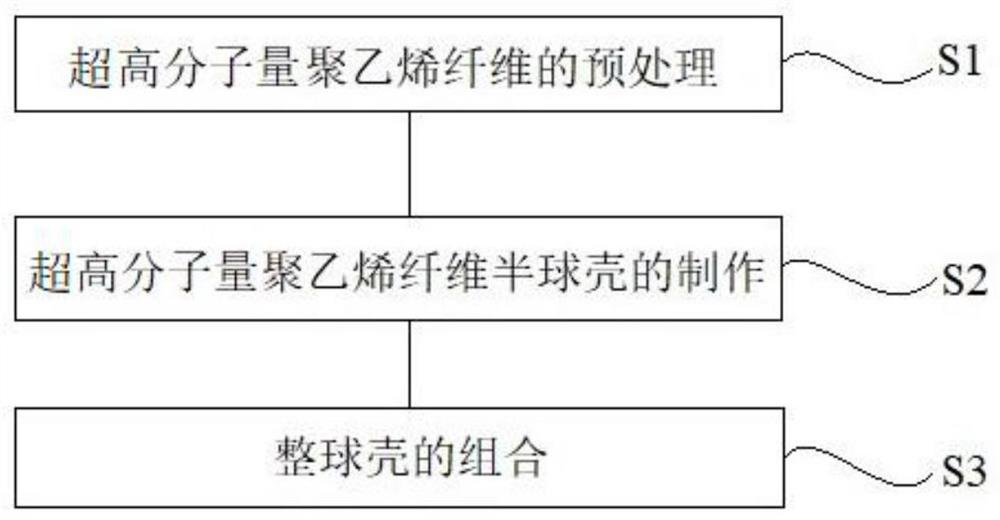

[0051] like Figure 4 As shown, the energy-absorbing protection structure of the ceramic hollow buoyancy ball according to the embodiment of the present invention includes an ultra-high molecular weight polyethylene fiber 2 and a resin layer, and the ultra-high molecular weight polyethylene fiber 2 is evenly coated on any equator on the surface of the ceramic hollow buoyancy ball 1. , forming an ultra-high molecular weight polyethylene fiber layer, and coating an epoxy resin layer on the ultra-high molecular weight polyethylene fiber layer to cure the ultra-high molecular weight polyethylene fiber layer. The thickness of UHMWPE fiber layer is 20mm, and the material density of UHMWPE fiber 2 is 1g / cm 3 .

[0052] When the ceramic hollow buoyancy ball implodes in the deep sea, because the ball is wrapped with an energy-absorbing and explosion-proof ultra-high molecular weight polyethylene fiber layer, when the shell is damaged, no flying ceramic fragments will be generated, and...

Embodiment 3

[0057] The energy absorption protection structure of the ceramic hollow buoyancy ball according to the embodiment of the present invention includes a first hemispherical shell, a second hemispherical shell, an ultra-high molecular weight polyethylene fiber layer and a resin cured layer.

[0058] The thickness of the first hemispherical shell and the second hemispherical shell are both 3 mm, and there are water through holes thereon. The first hemispherical shell 2 and the second hemispherical shell 3 are combined by locking components to form a spherical shell. The first hemispherical shell 2 and the second hemispherical shell 3 are made of ultra-high molecular weight polyethylene fiber material with a material density of 0.95g / cm 3 .

[0059] Any equator on the surface of the spherical shell formed by the combination is uniformly coated with multiple layers of ultra-high molecular weight polyethylene fibers to form a plurality of ultra-high molecular weight polyethylene fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com