A preparation method of graphene-enhanced biomass porous carbon electromagnetic wave-absorbing material

A technology of electromagnetic wave absorption and porous carbon, which is applied in the preparation/purification of carbon, chemical instruments and methods, and other chemical processes. The effect of improved performance, good electromagnetic wave absorption performance, good electromagnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

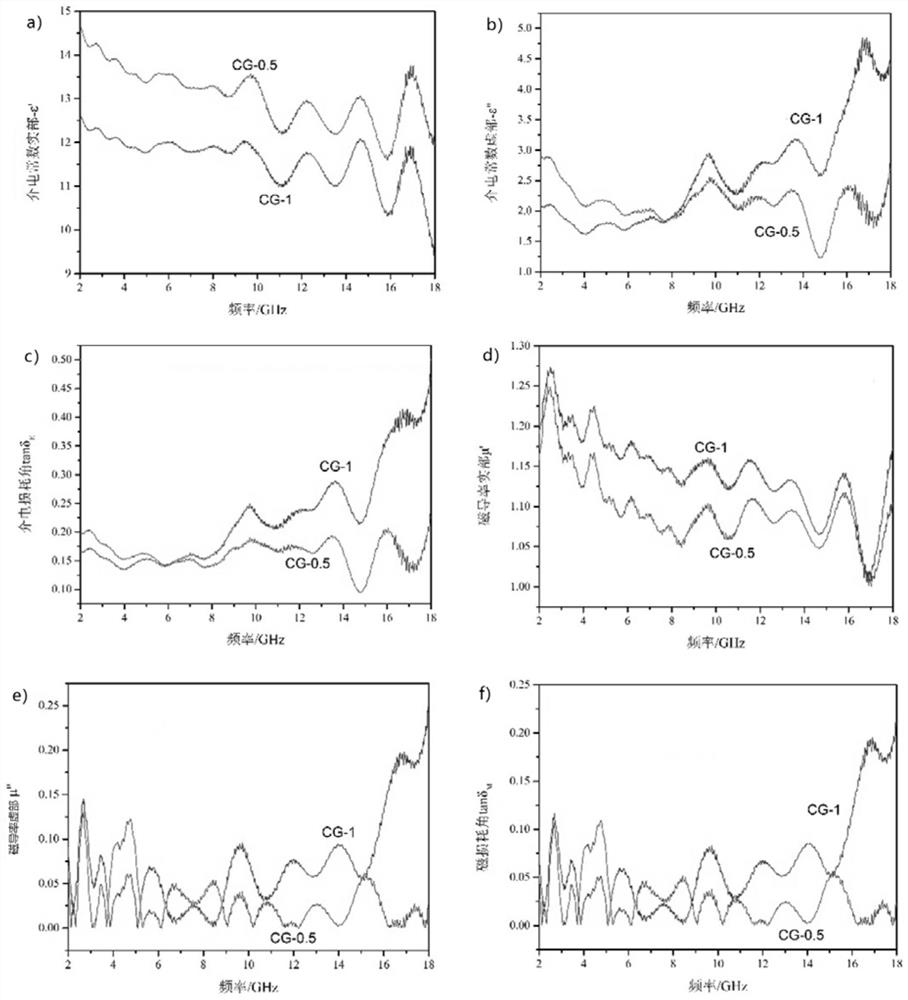

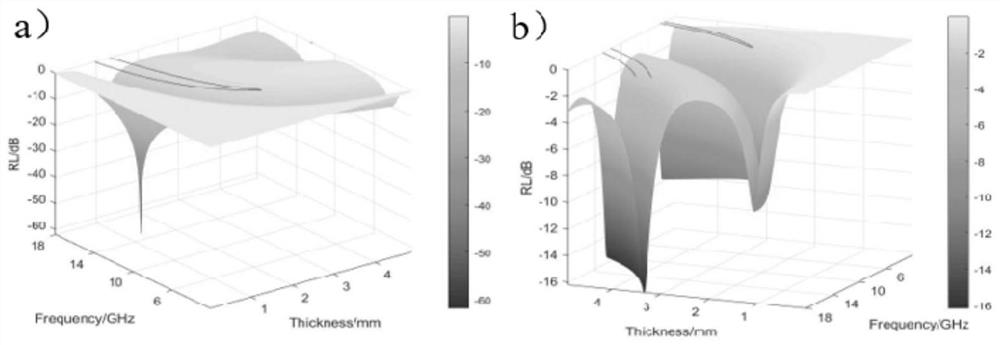

Examples

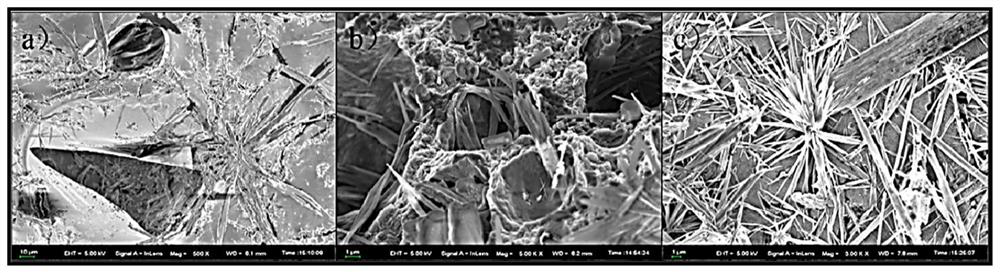

Embodiment 1

[0051] A graphene-enhanced biomass porous carbon electromagnetic wave-absorbing material, which is prepared according to the following steps:

[0052] Step 1, pretreatment of egg white:

[0053] Use physical dispersion to pretreat the egg white to obtain a uniform protein solution. The specific steps are as follows: separate the fresh egg white from the egg, and use an ultrasonic cell pulverizer to ultrasonically pulverize it to obtain a uniform protein (as the main component) solution. Wherein: the mass fraction of protein in the protein solution is 10wt% (the mass fraction of protein in the protein solution obtained by different eggs will be different); the power of ultrasonic pulverization is 15% of the power of ultrasonic cell pulverizer, pulverization time 2min;

[0054] Step 2, preparation of graphene oxide slurry:

[0055] Graphene oxide powder is dissolved in deionized water to obtain graphene oxide slurry, wherein: the concentration of the graphene oxide slurry is 1...

Embodiment 2

[0066] In this embodiment, the graphene-enhanced biomass porous carbon electromagnetic absorbing material is realized in the following steps:

[0067] Step 1, pretreatment of egg white:

[0068] Use physical dispersion to pretreat the egg white to obtain a uniform protein solution. The specific steps are as follows: separate the fresh egg white from the egg, and use an ultrasonic cell pulverizer to ultrasonically pulverize it to obtain a uniform protein (as the main component) solution. Wherein: the mass fraction of protein in the protein solution is 10wt% (the mass fraction of protein in the protein solution obtained by different eggs will be different); the power of ultrasonic pulverization is 15% of the power of ultrasonic cell pulverizer, pulverization time 2min;

[0069] Step 2, preparation of graphene oxide slurry:

[0070] Graphene oxide powder is dissolved in deionized water to obtain graphene oxide slurry, wherein: the concentration of the graphene oxide slurry is 5...

Embodiment 3

[0081] In this embodiment, the graphene-enhanced biomass porous carbon electromagnetic absorbing material is realized in the following steps:

[0082] Step 1, pretreatment of egg white:

[0083] Use physical dispersion to pretreat the egg white to obtain a uniform protein solution. The specific steps are as follows: separate the fresh egg white from the egg, and use an ultrasonic cell pulverizer to ultrasonically pulverize it to obtain a uniform protein (as the main component) solution. Wherein: the mass fraction of protein in the protein solution is 10wt% (the mass fraction of protein in the protein solution obtained by different eggs will be different); the power of ultrasonic pulverization is 15% of the power of ultrasonic cell pulverizer, pulverization time 2min;

[0084] Step 2, preparation of graphene oxide slurry:

[0085] Graphene oxide powder is dissolved in deionized water to obtain graphene oxide slurry, wherein: the concentration of the graphene oxide slurry is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com