Installation structure for drainage pipeline and installation process thereof

A technology for installing structures and drainage pipes, which is applied in the sewer system, waterway system, water supply device, etc., can solve the problem of easy damage of the pipe body, and achieve the effect of improving the convenience of construction and improving the anti-settling ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

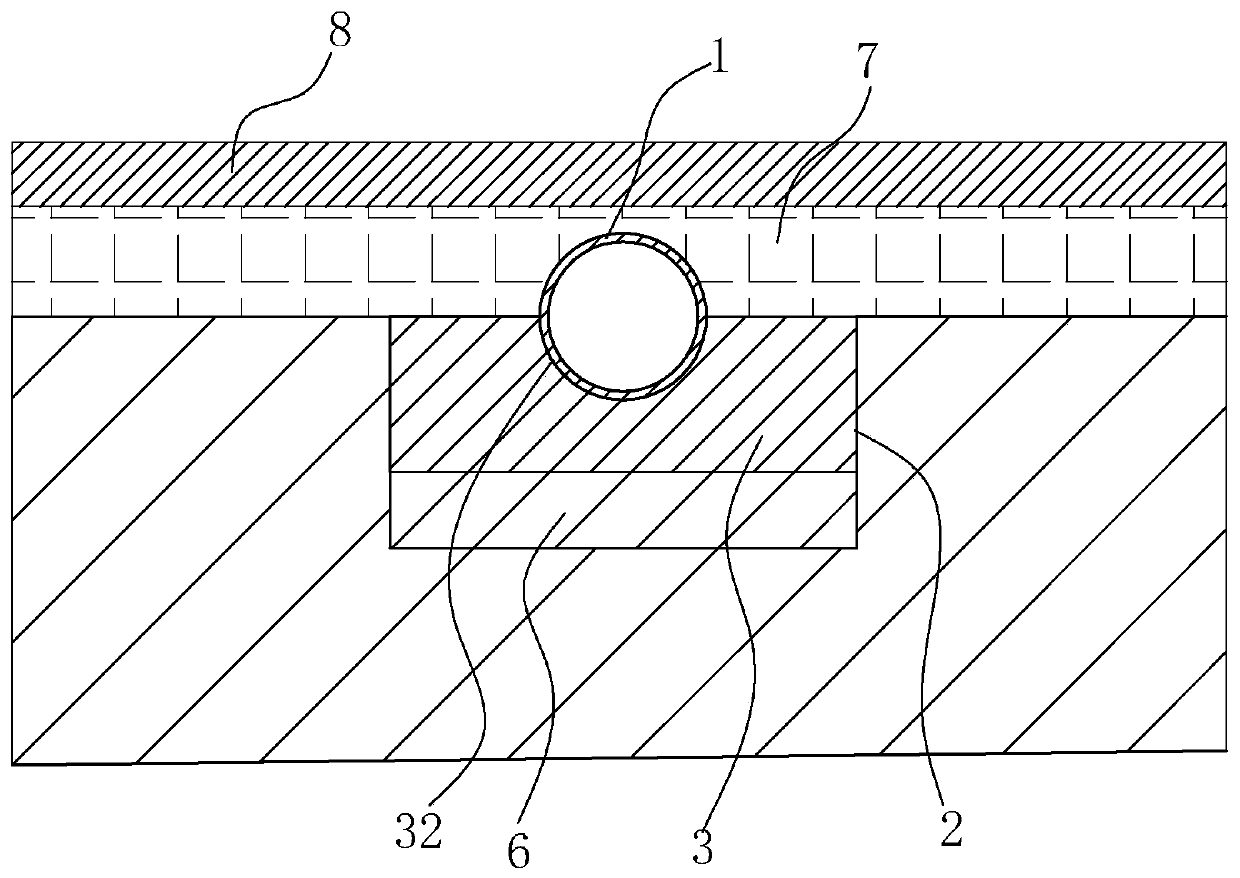

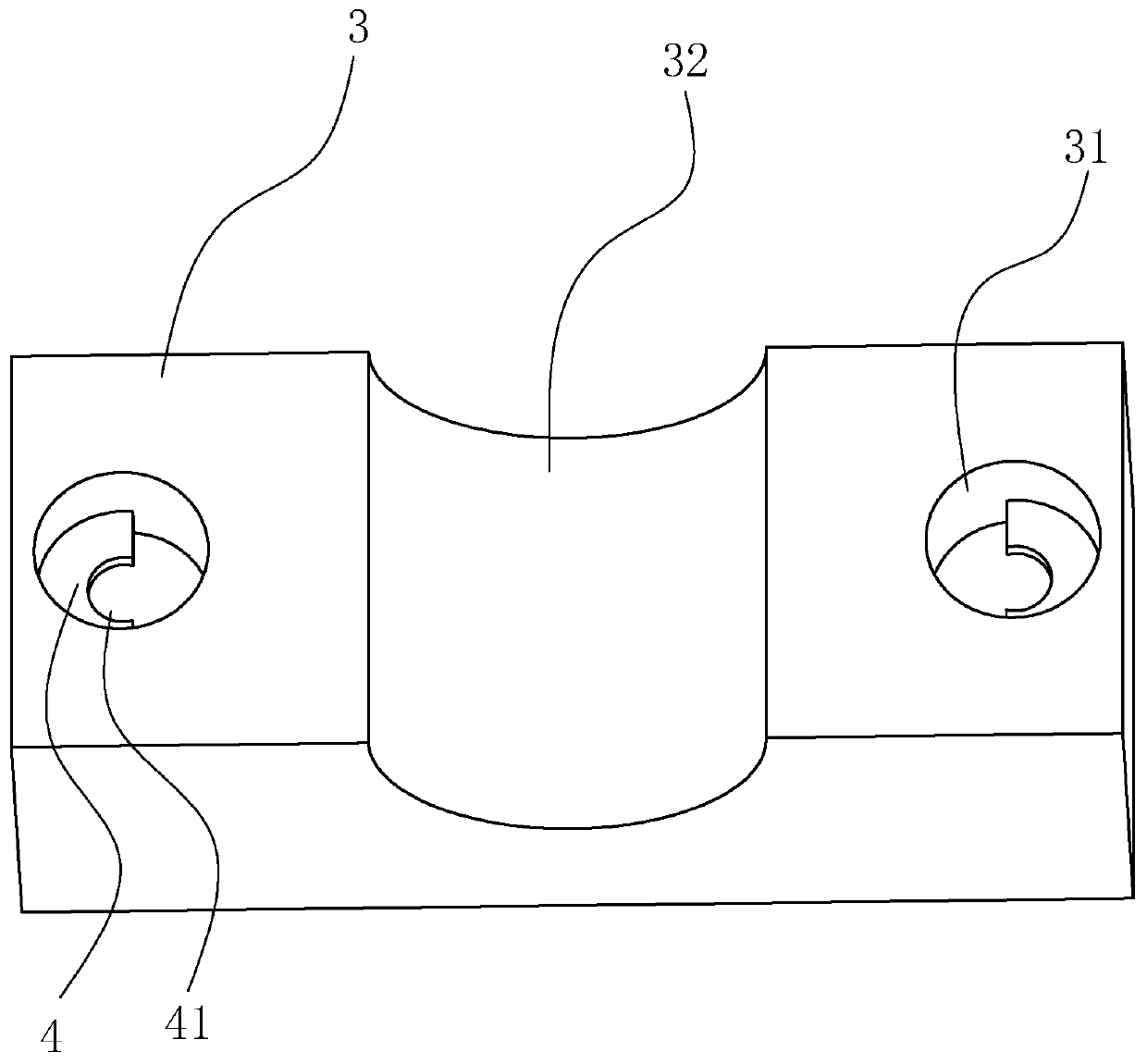

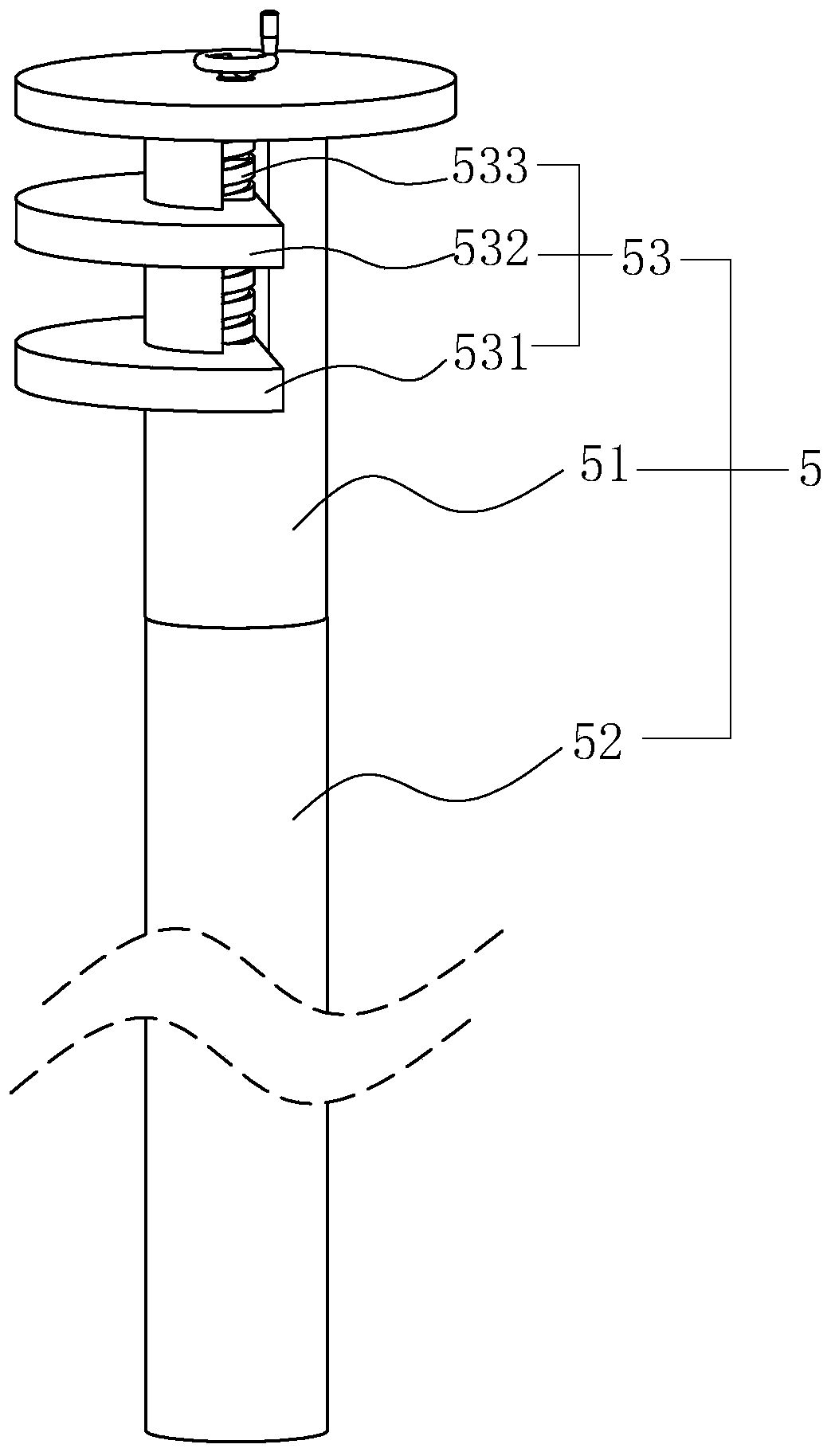

[0046] An installation structure for a drainage pipe, combined with figure 1 with Figure 4 , a groove 2 is opened on the ground, and the bottom of the groove 2 is formed by concrete pouring to form a concrete reinforcement layer 6, and a support seat 3 is installed on the top of the concrete reinforcement layer 6 along the extension direction of the groove 2, and the upper part of the support seat 3 The surface is laid with a pipe body 1, the pipe body 1 is provided with multiple sections, and the multi-section pipe bodies 1 are plugged and matched with each other. In the settling assembly 5 , a protective layer 7 and a cladding layer 8 are sequentially provided above the support base 3 from bottom to top, and the protective layer 7 completely submerges the top of the pipe body 1 . The concrete reinforcement layer 6 can tamp the bottom of the groove 2, and the support seat 3 can support and limit the pipeline body 1, so that the pipeline body 1 has high stability after layin...

Embodiment 2

[0057] The installation process of the drainage pipe includes the following steps:

[0058] S1, measuring and setting out and excavating trench 2: the excavation depth of trench 2 is 2.5-4.5 meters. In this embodiment, the preferred trench 2 depth is 4 meters, and trenches are excavated in relatively loose soil areas 2. Finally, drive steel piles into the groove wall of groove 2 to form a retaining wall structure. The driving depth of steel piles is 2-3 meters downward from the bottom of groove 2;

[0059] S2. Excavating the docking hole 21: measure and locate the position of the docking hole 21, dig out the docking hole 21, the excavation depth of the docking hole 21 is 0.5-2 meters, the preferred embodiment is 0.5 meters, and to the docking hole 21 Insert the mold column to isolate and protect the butt hole 21;

[0060] S3. Constructing the reinforced concrete layer 6: placing a reinforcement cage at the bottom of the trench 2 and pouring concrete to form the reinforced con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com