Water-based electromagnetic shielding coating and preparation method and application thereof

An electromagnetic shielding coating, water-based technology, used in conductive coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor adhesion, uneven dispersion, and harmful components of water-based electromagnetic shielding, and achieve stable storage and performance. , The effect of uniform arrangement and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned water-based electromagnetic shielding paint. The preparation method of described water-based electromagnetic shielding paint comprises the steps:

[0029] Step S01: weighing each component according to the ratio of the components contained in the water-based electromagnetic shielding coating and the components described above;

[0030] Step S02: Mixing the components weighed in step S01.

[0031] Specifically, the preferred contents and types of the components of the water-based electromagnetic shielding paint in the above step S01 are as described above, and will not be repeated here to save space.

[0032]The mixing process in the above step S02 can be processed in a conventional way, such as stirring, ultrasonic treatment, etc., so that the components are uniformly dispersed. In one embodiment, the mixing process in step S02 is to first add functional ...

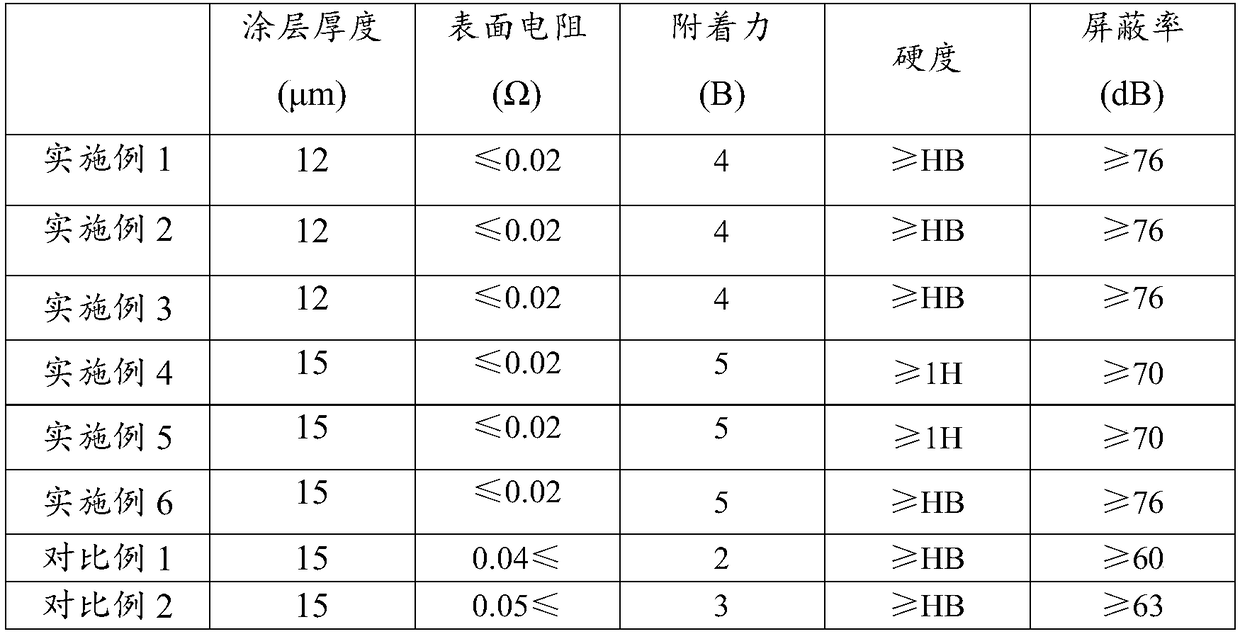

Embodiment 1

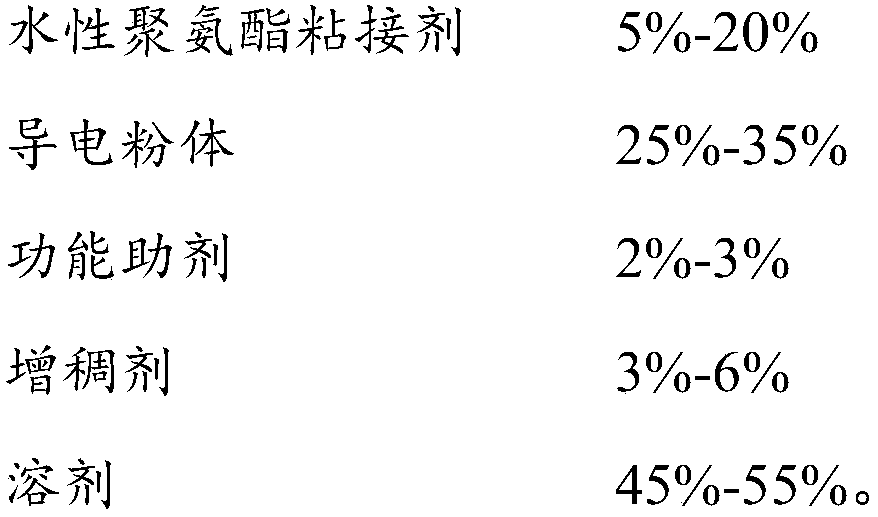

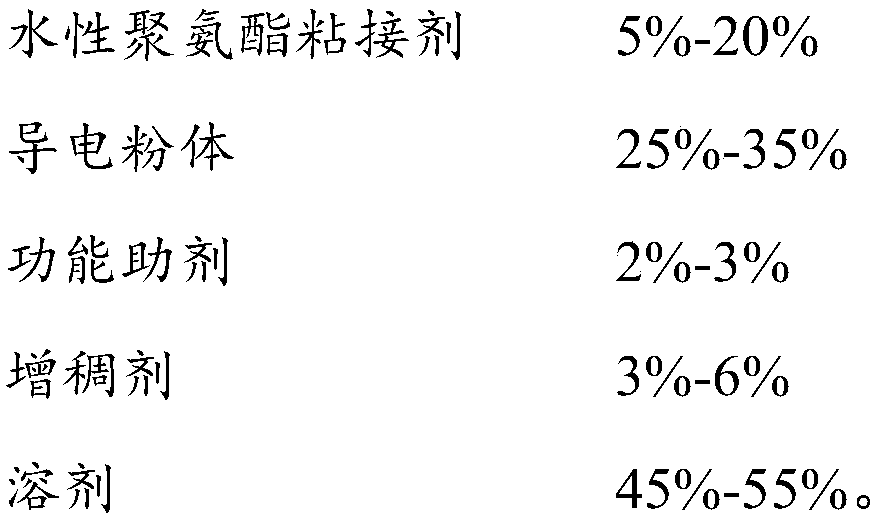

[0037] The present embodiment provides a water-based electromagnetic shielding coating and a preparation method thereof, which includes the following components by weight:

[0038] Water-based emulsified water-dispersed resin 7%, silver-coated copper powder 35%, methylethanolamine 3.5%, hydrophobically modified acrylic acid associative thickener 5.5%, absolute ethanol 18%, propylene glycol methyl ether acetate 5%, isopropyl Alcohol 26%. Wherein, the average particle diameter of the silver-coated copper powder is 7±1 μm.

[0039] The preparation method of the water-based electromagnetic shielding coating of the present embodiment may further comprise the steps:

[0040] S11. Weighing: Weigh water-based emulsified water-dispersed resin, silver-coated copper powder, methylethanolamine, hydrophobically modified acrylic acid associative thickener, absolute ethanol, propylene glycol methyl ether acetate, iso Components such as propanol;

[0041] S12. Preparation of slurry: Under ...

Embodiment 2

[0043] The present embodiment provides a water-based electromagnetic shielding coating and a preparation method thereof, which includes the following components by weight:

[0044] Water-based emulsified water-dispersed resin 10%, silver-coated copper powder 35%, methylethanolamine 3.5%, hydrophobically modified acrylic acid associative thickener 5.5%, absolute ethanol 20%, propylene glycol methyl ether acetate 5%, isopropyl Alcohol 21%. Wherein, the average particle diameter of the silver-coated copper powder is 7±1 μm.

[0045] The preparation method of the water-based electromagnetic shielding coating of the present embodiment may further comprise the steps:

[0046] S11. Weighing: Weigh water-based emulsified water-dispersed resin, silver-coated copper powder, methylethanolamine, hydrophobically modified acrylic acid associative thickener, absolute ethanol, propylene glycol methyl ether acetate, iso Components such as propanol;

[0047] S12. Preparation of slurry: Under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com