Mounting structure for in-position device of prefabricated concrete wallboard

A technology for concrete walls and installation structures, which is applied in the direction of building construction, construction, and building materials processing. It can solve the problems of difficult disassembly of the installation structure, damage to the in-place setting, and lack of buffer protection, etc., so as to avoid replacement of equipment or materials. , Avoid excessive impact force, convenient disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

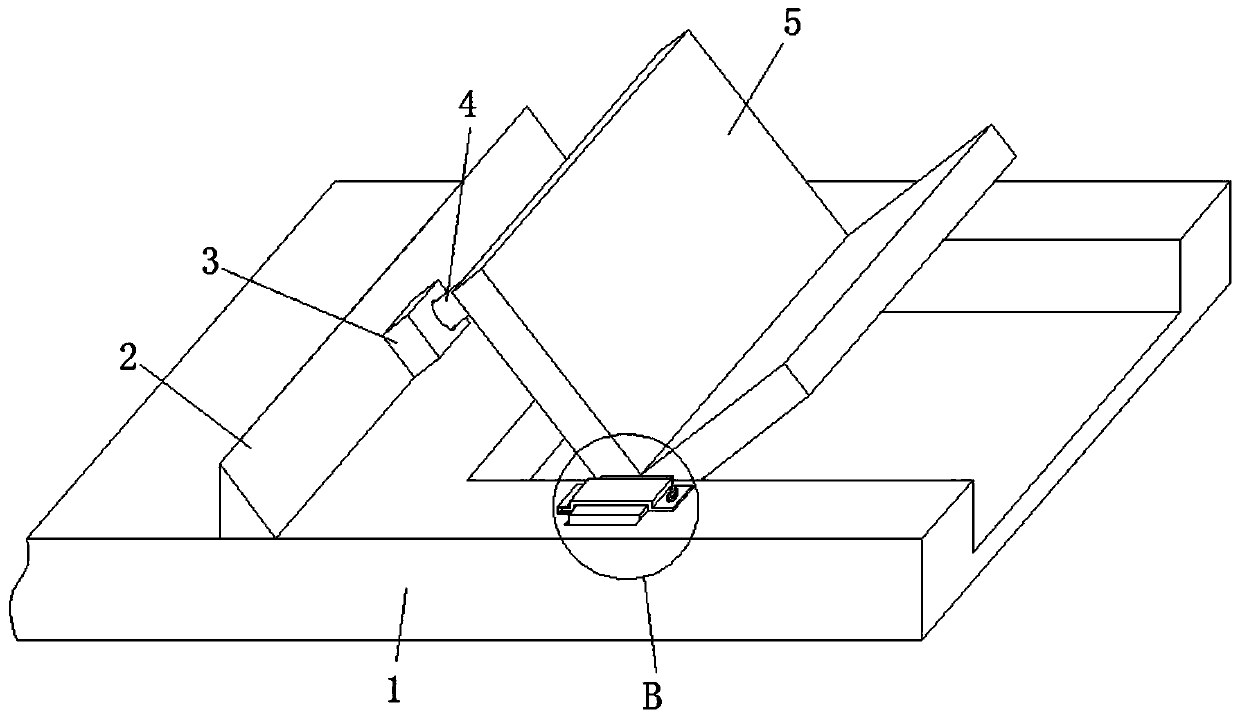

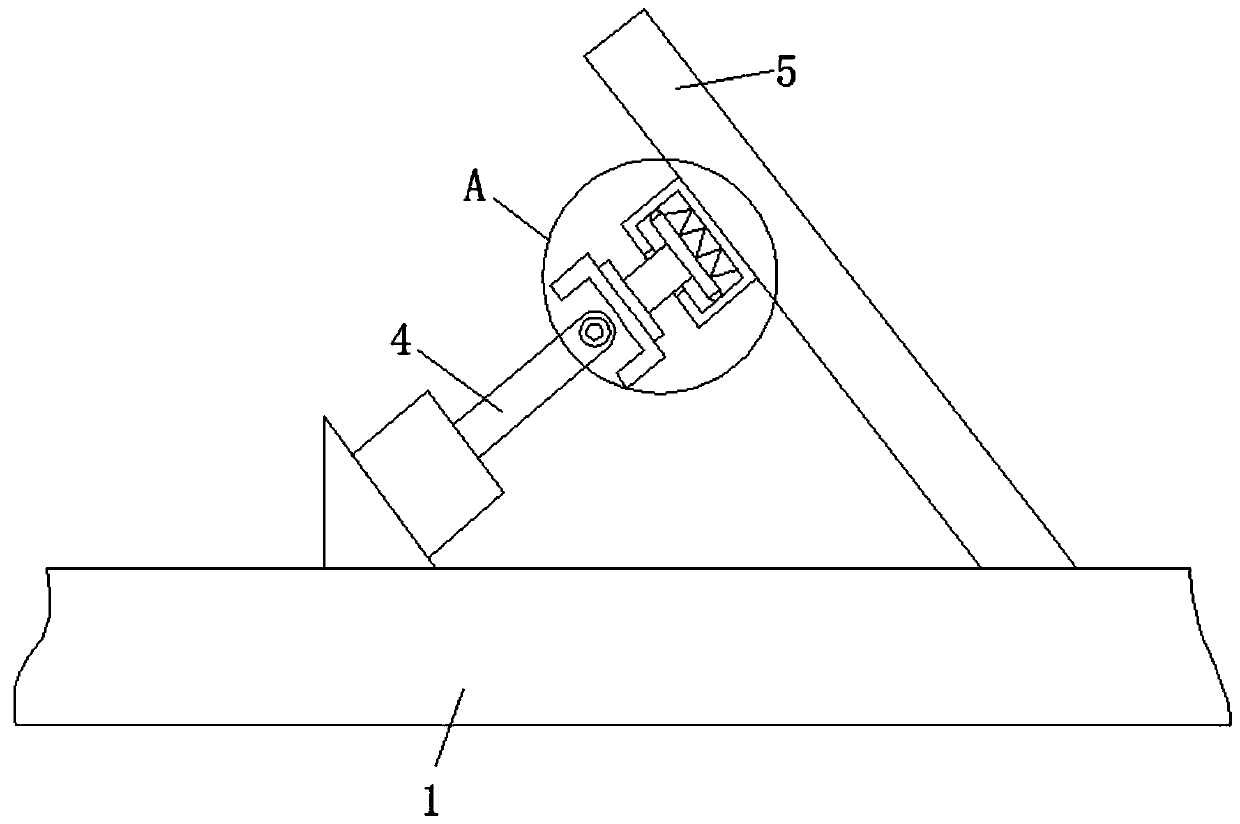

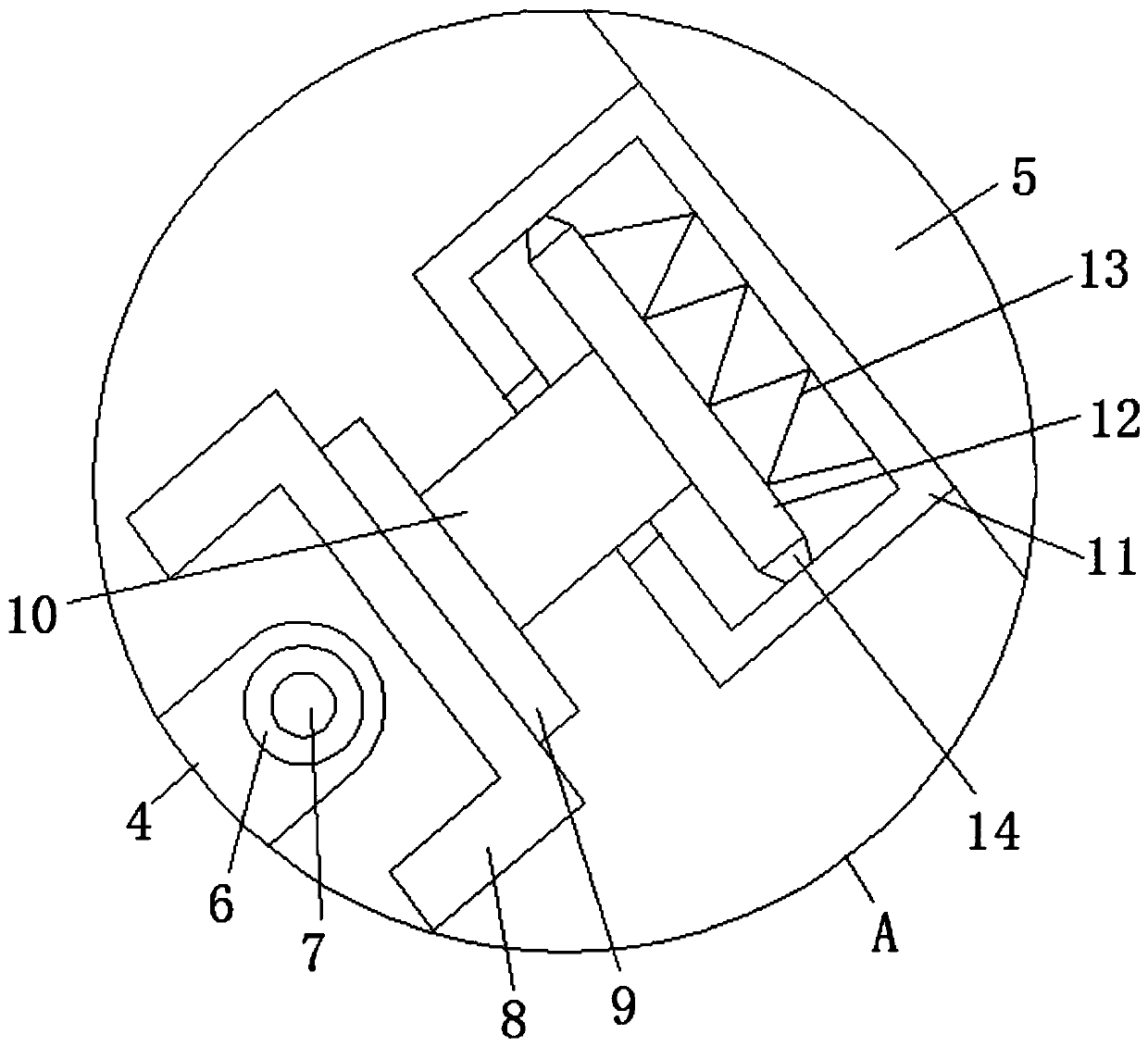

[0033] Attached below Figure 1-7 The present invention is further described with embodiment:

[0034] An installation structure for prefabricated concrete wall panel positioning equipment, including a positioning equipment support plate 1, a triangular fixing plate 2 is arranged on the upper plate of the positioning equipment supporting plate 1, and a hydraulic cylinder is arranged on the hypotenuse of the triangular fixing plate 2 3. The output end of the hydraulic cylinder 3 is connected with a hydraulic rod 4, the upper end of the hydraulic rod 4 extends into the installation groove 8, and a section of the hydraulic rod 4 located in the installation groove 8 is provided with a left and right through installation through hole 6, the installation through hole The movable pin 7 is arranged in the 6, and the movable pin 7 is detachably arranged on the installation groove 8, and the outer top plate of the installation groove 8 is fixedly provided with a fixed seat 9, and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com