Backwash-resistant flat sheet membrane and preparation method thereof

A flat membrane, backwashing technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. It can solve the problems of chemical cleaning frequency and other issues, so as to achieve the effect of saving chemical cost and labor cost, simple structure and improving fouling resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, objectives and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

[0018] A preferred embodiment of the present invention is to provide a kind of anti-backwashing flat membrane, the purpose is to set anchor points for fixing the filter membrane on both sides of the deflector, the anchor points are evenly set to fix the filter membrane, so that the flat membrane can It can improve the anti-fouling resistance while being resistant to backwashing, ensure the water output, reduce the frequency of chemical cleaning of the flat membrane, save the cost of chemicals and labor costs, and has a simple structure and is easy to use.

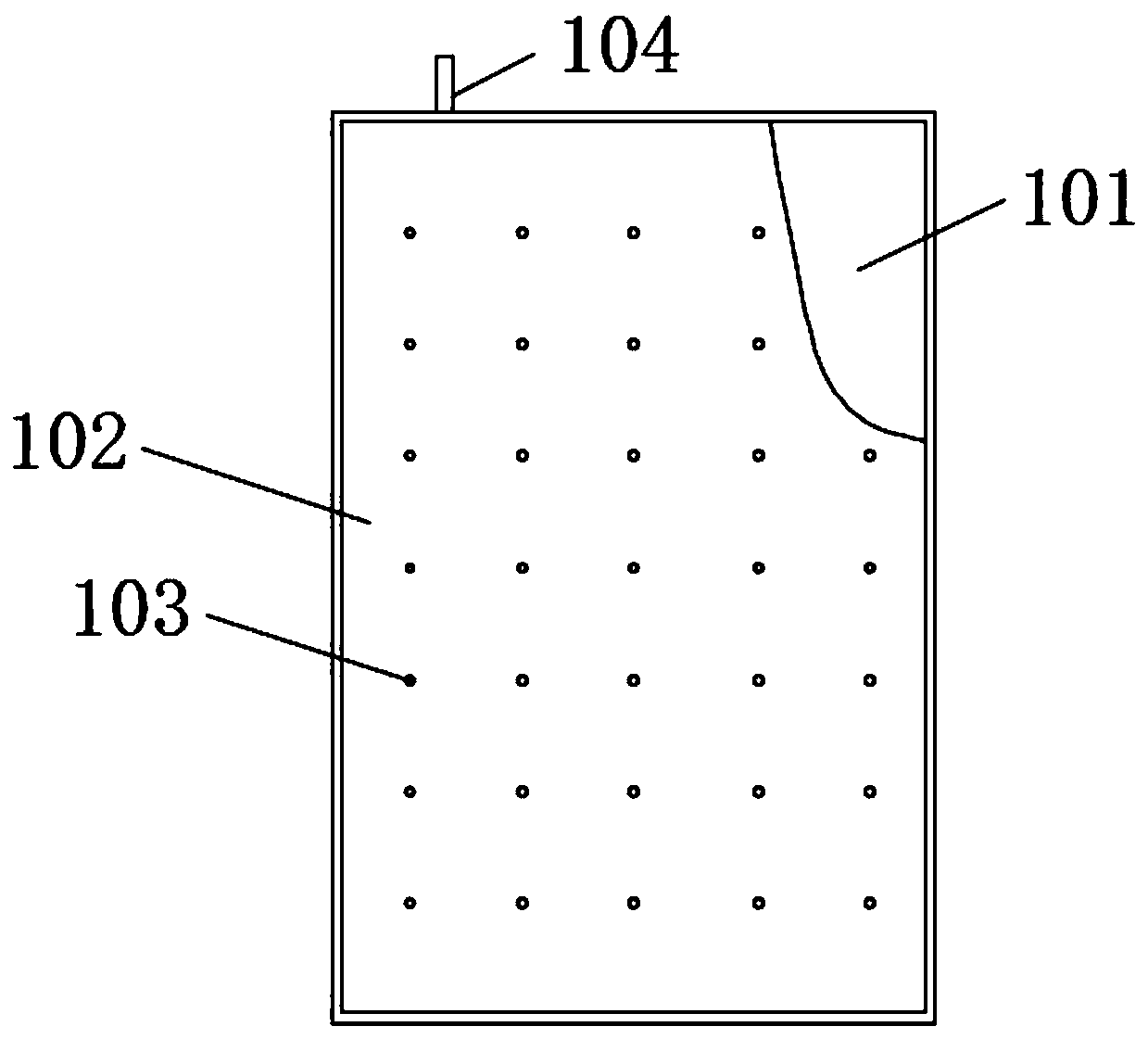

[0019] Such as figure 1 As shown, a backwash-resistant flat membrane, including a deflector 101 and a filter membrane 102, the filter membrane 102 is connected to the deflector 101 through a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com