Reduction method and device

A technology of reduction and reduction roll, which is applied in the field of continuous casting technology, can solve the problems that the quality of the core of the continuous casting billet cannot be further mentioned, and cannot improve the looseness and shrinkage of the core of the continuous casting billet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

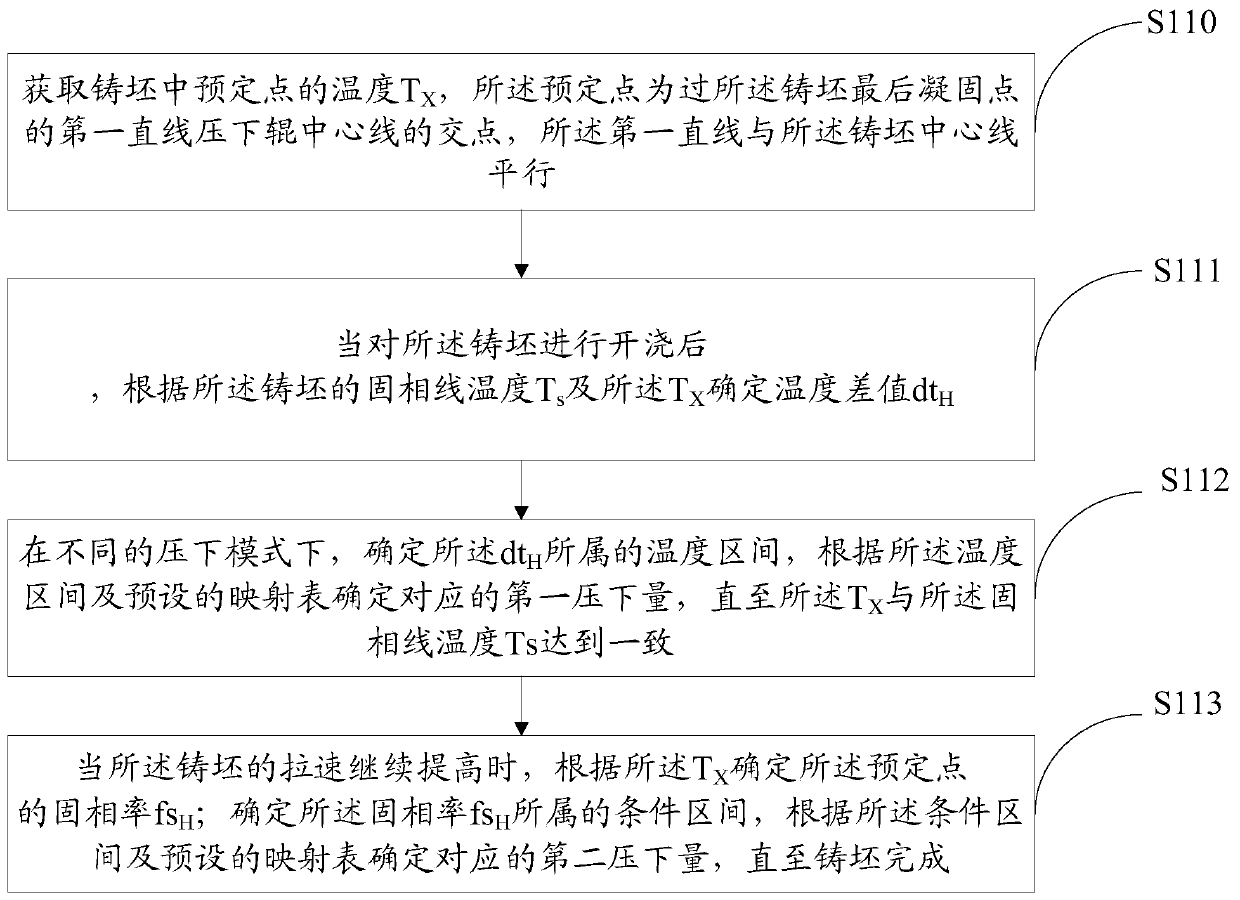

[0049] This embodiment provides a pressing method, such as figure 1 As shown, the methods include:

[0050] S110, obtaining the temperature T of a predetermined point in the slab X , the predetermined point is the intersection of the first straight line passing through the final solidification point of the slab and the centerline of the pressing roller, and the first straight line is parallel to the centerline of the slab;

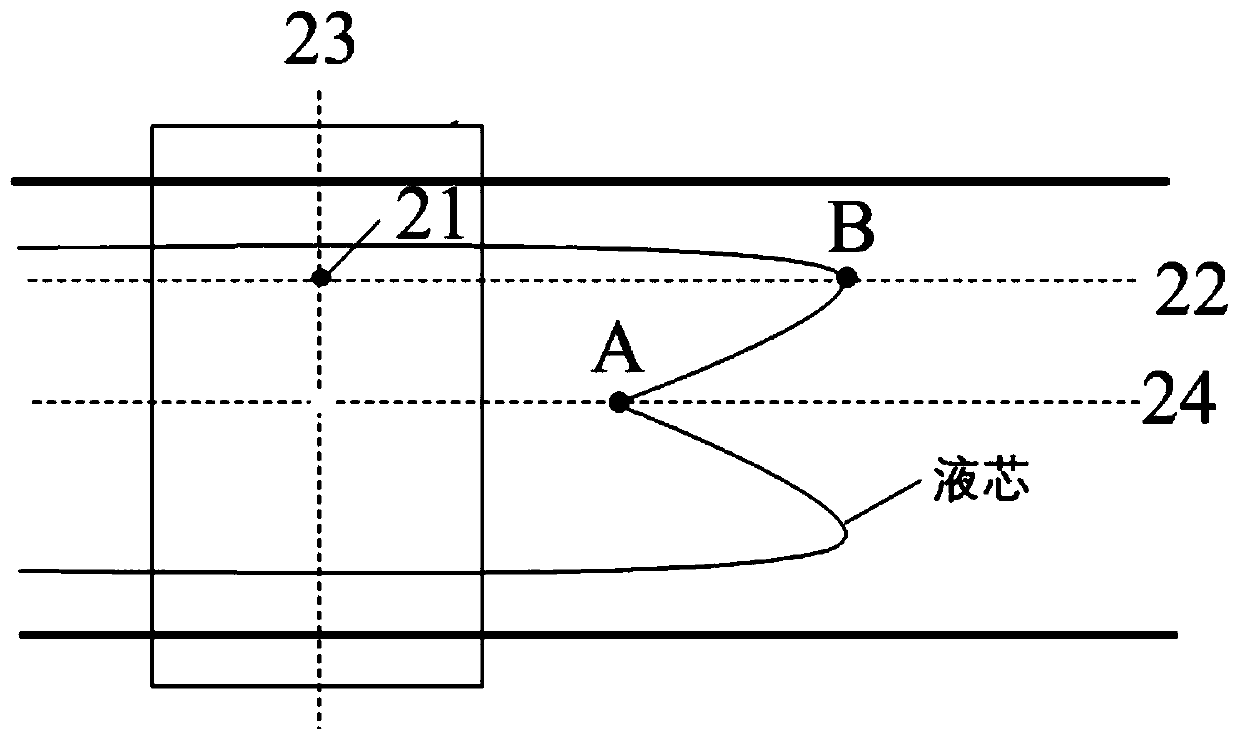

[0051] In the continuous casting process, the temperature T at a predetermined point in the slab is obtained X . Usually, the shape of the solidification front of the slab is irregular, and there is a certain distance between the first solidification point and the last solidification point, and they are distributed in a W shape, and the solidification morphology is as follows: figure 2 shown.

[0052] The first solidification point is generally at the center of the slab, such as figure 2 Mark A in , and the final freezing point is shown in Mark B. ...

Embodiment 2

[0100] Corresponding to Embodiment 1, this embodiment also provides a pressing device, such as image 3 As shown, the device includes: an acquisition unit 31, a first determination unit 32 and a second determination unit 33;

[0101] The acquisition unit 31 is used to acquire the temperature T of a predetermined point in the slab X . Usually, the shape of the solidification front of the slab is irregular, and there is a certain distance between the first solidification point and the last solidification point, and they are distributed in a W shape, and the solidification morphology is as follows: figure 2 shown. The first solidification point is generally at the center of the slab, and the last solidification point is between the center and the surface of the slab.

[0102] exist figure 2 Among them, the predetermined point 21 is the intersection point of the first straight line 22 passing through the final solidification point of the slab and the centerline 23 of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com