Automatic screw mounting equipment

A technology of automatic installation and equipment, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as affecting mold processing efficiency, screw installation position deviation, difficult operation, etc., to ensure high efficiency, stability, and high-precision movement. Distance, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

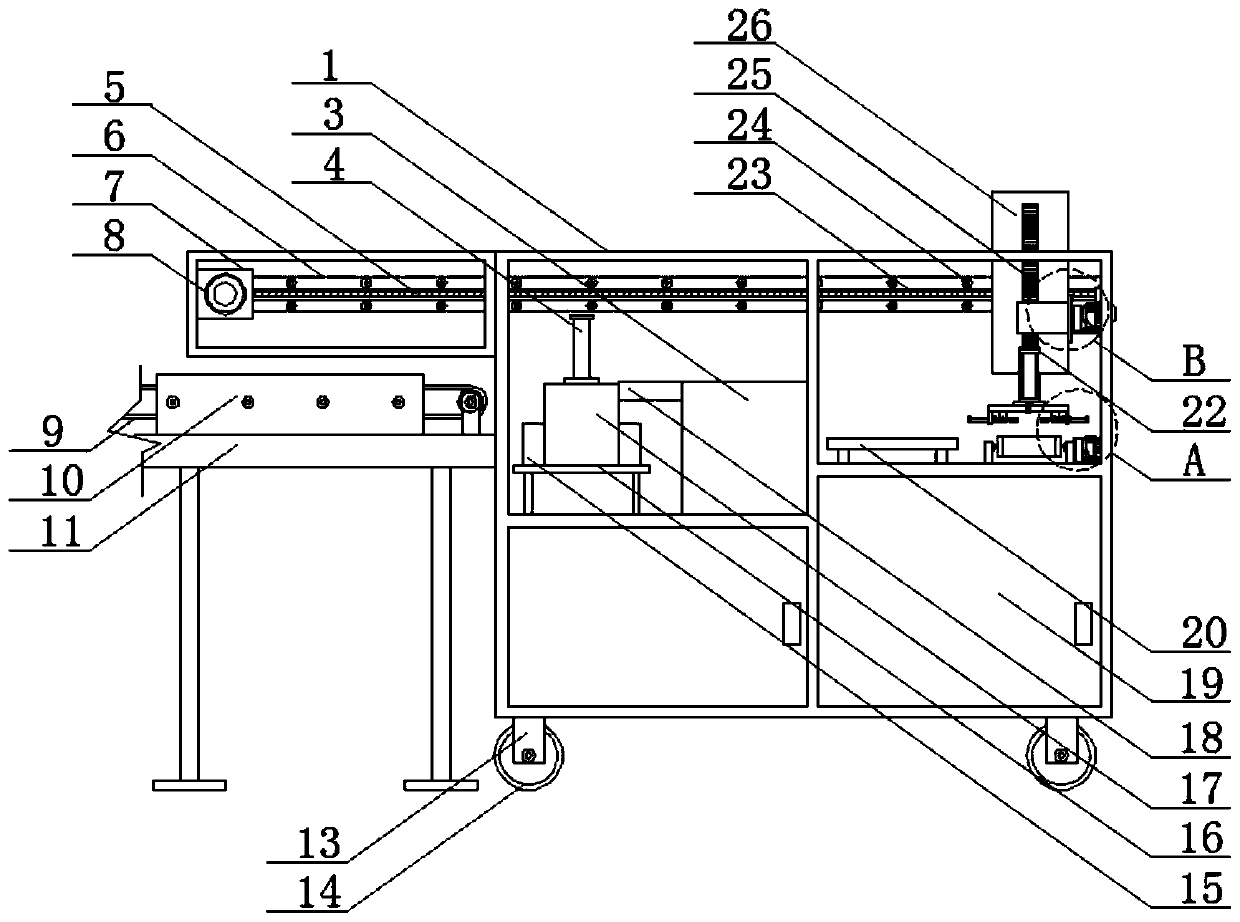

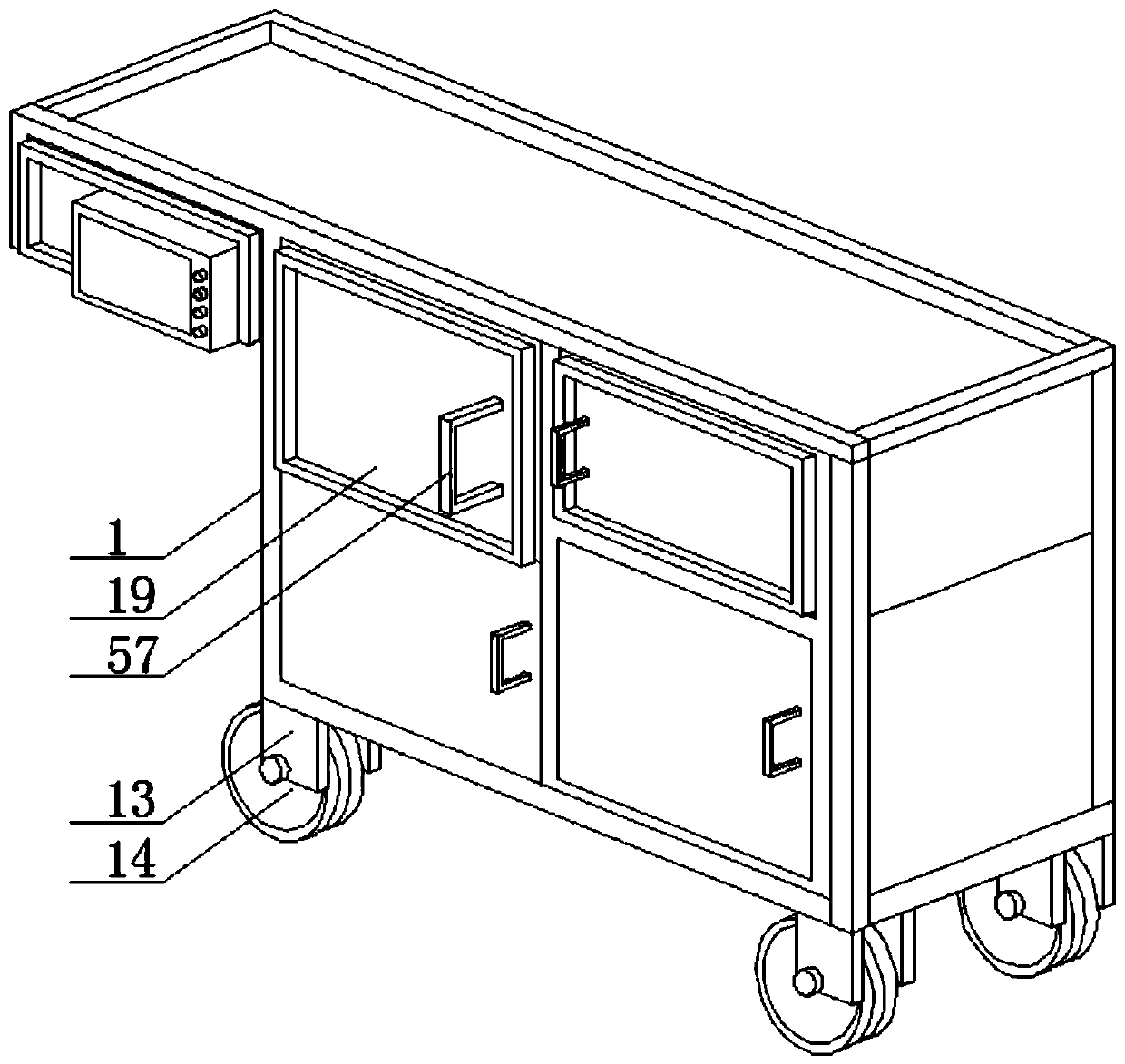

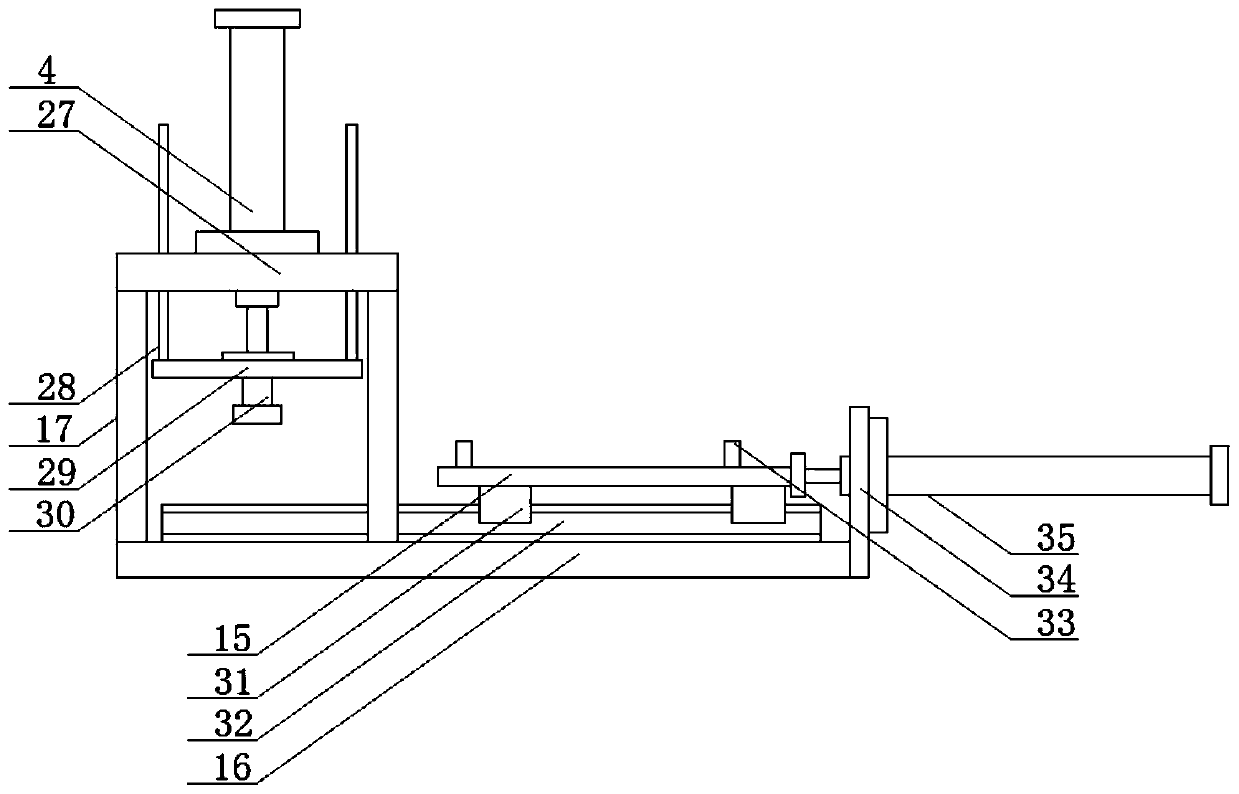

[0035] refer to figure 1 , 2 , 3, 4, 5, 6, 7, 8, a screw automatic installation device, including a shell 1, which plays a protective role, and the opposite side walls in the shell 1 are jointly fixed with partitions, and the partitions will The housing 1 is divided into a cavity and a placement cavity, which is convenient for partition placement. A mounting plate 6 is detachably connected to the side wall at one end of the cavity by more than two screws 24. One side of the mounting plate 6 is provided with a first chute 23, the first chute 23 is provided with an adjustment device, the adjustment device is provided with a fixed box 26, the movement of the adjustment device drives the fixed box 26 to move, the fixed box 26 is provided with a lifting device, the lifting device is provided with a rack 25, fixed One side of the box 26 is provided with a rotating device, the rotating device and the rack 25 are connected to each other, and the rotating device rotates to drive the r...

Embodiment 2

[0049] refer to figure 1 , 2 , 3, 4, 5, 6, 7, 8, a screw automatic installation device, including a shell 1, which plays a protective role, and the opposite side walls in the shell 1 are jointly fixed with partitions, and the partitions will The housing 1 is divided into a cavity and a placement cavity, which is convenient for partition placement. A mounting plate 6 is detachably connected to the side wall at one end of the cavity by more than two screws 24. One side of the mounting plate 6 is provided with a first chute 23, the first chute 23 is provided with an adjustment device, the adjustment device is provided with a fixed box 26, the movement of the adjustment device drives the fixed box 26 to move, the fixed box 26 is provided with a lifting device, the lifting device is provided with a rack 25, fixed One side of box 26 is provided with rotating device, and rotating device is connected with tooth bar 25, and rotating device rotates and drives tooth bar 25 to move, and ...

Embodiment 3

[0064] refer to figure 1 , 2 , 3, 4, 5, 6, 7, 8, a screw automatic installation device, including a shell 1, which plays a protective role, and the opposite side walls in the shell 1 are jointly fixed with partitions, and the partitions will The housing 1 is divided into a cavity and a placement cavity, which is convenient for partition placement. A mounting plate 6 is detachably connected to the side wall at one end of the cavity by more than two screws 24. One side of the mounting plate 6 is provided with a first chute 23, the first chute 23 is provided with an adjustment device, the adjustment device is provided with a fixed box 26, the movement of the adjustment device drives the fixed box 26 to move, the fixed box 26 is provided with a lifting device, the lifting device is provided with a rack 25, fixed One side of the box 26 is provided with a rotating device, the rotating device and the rack 25 are connected to each other, and the rotating device rotates to drive the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com