Composite foam sandwich structure and forming method thereof

A composite material and sandwich structure technology, which is applied in the field of composite material foam sandwich structure and its molding, can solve the problems of poor molding quality and easy collapse of foam, and achieve the effect of improving strength and meeting processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

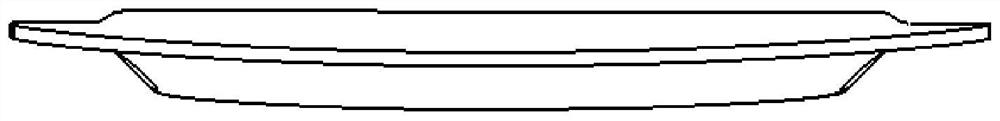

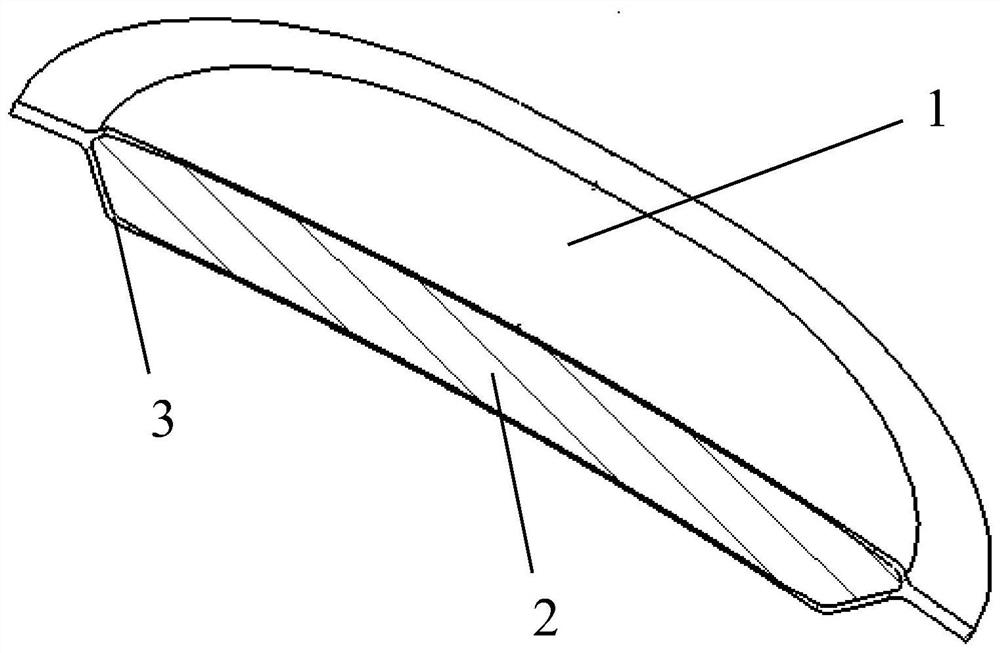

[0067] Forming a special-shaped composite foam sandwich cover structure, such as figure 2 and image 3 As shown, it includes the lower panel skin of the flap (the lower foam skin 3), the dimension foam core material 2 and the upper panel skin of the flap (the upper foam skin 1), the lower panel skin of the flap and the described The upper panel skin of the cover adopts 8522 high temperature epoxy prepreg material, and the dimensional foam core material adopts domestic PMI foam core material.

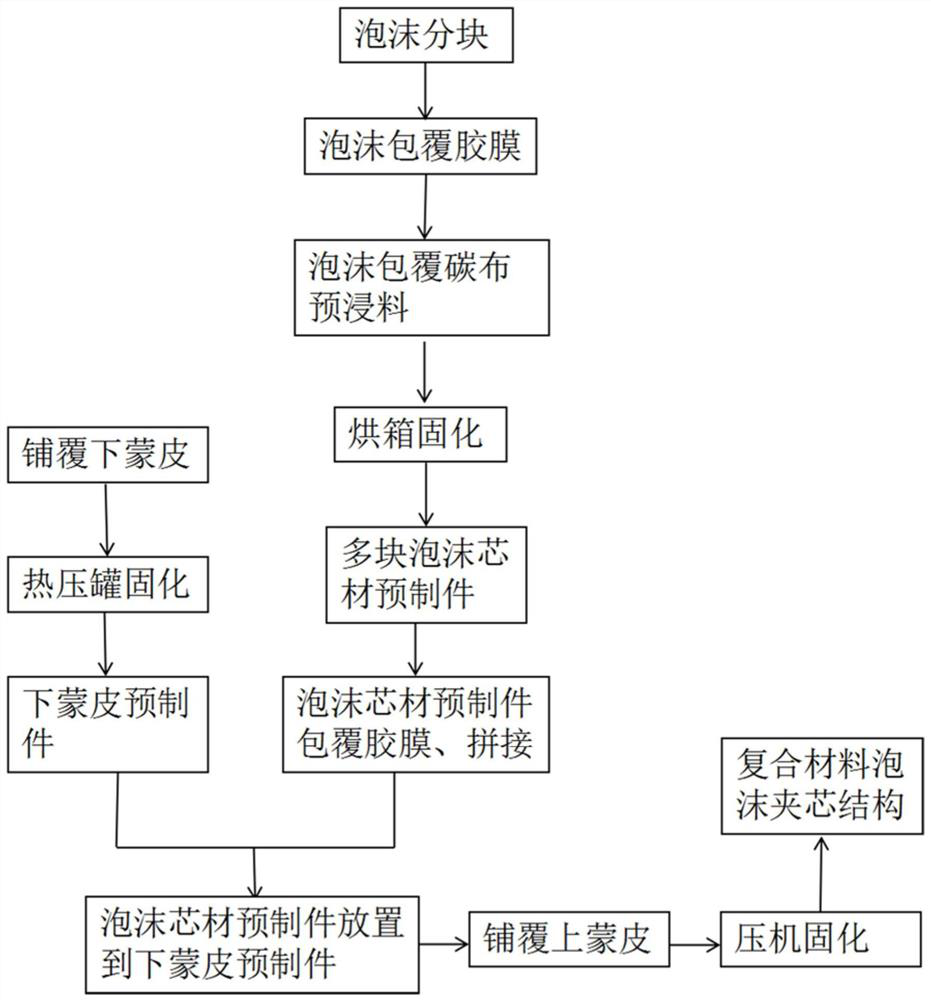

[0068] The specific preparation process of the shaped composite material foam sandwich lid structure is realized through the following steps:

[0069] (1) The prefabricated body of the lower panel skin (lower skin) of the special-shaped composite foam sandwich cover structure is cured and formed:

[0070] Lay 8522 high-temperature epoxy prepreg in the lower mold for forming the lid to obtain the lower panel skin prefabricated body, put the mold into the autoclave, and coat the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com