a ti/comoo 4 Preparation method of nano-array electrode

A nano-array and electrode technology, which is applied in the field of electrochemical water pollution control, can solve the problems of short service life of electrodes, complicated preparation process, easy diffusion of oxygen atoms, etc., and achieve stable electrode performance, simple preparation process and firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

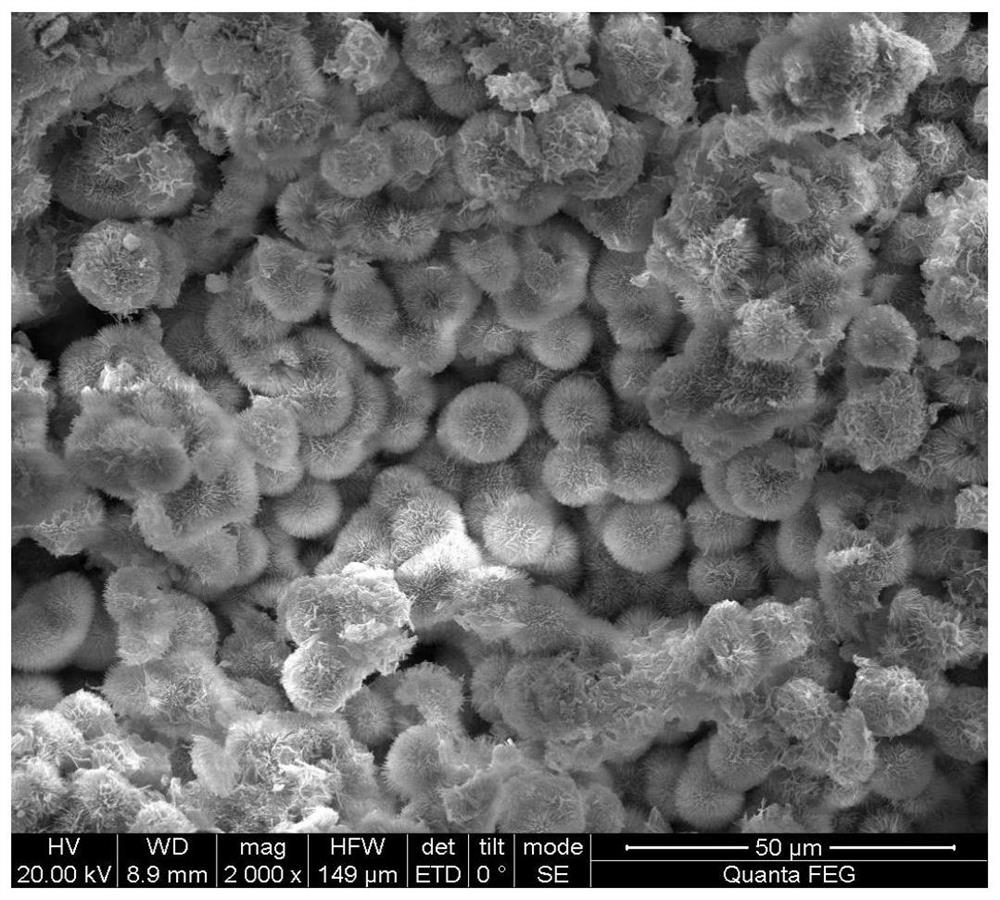

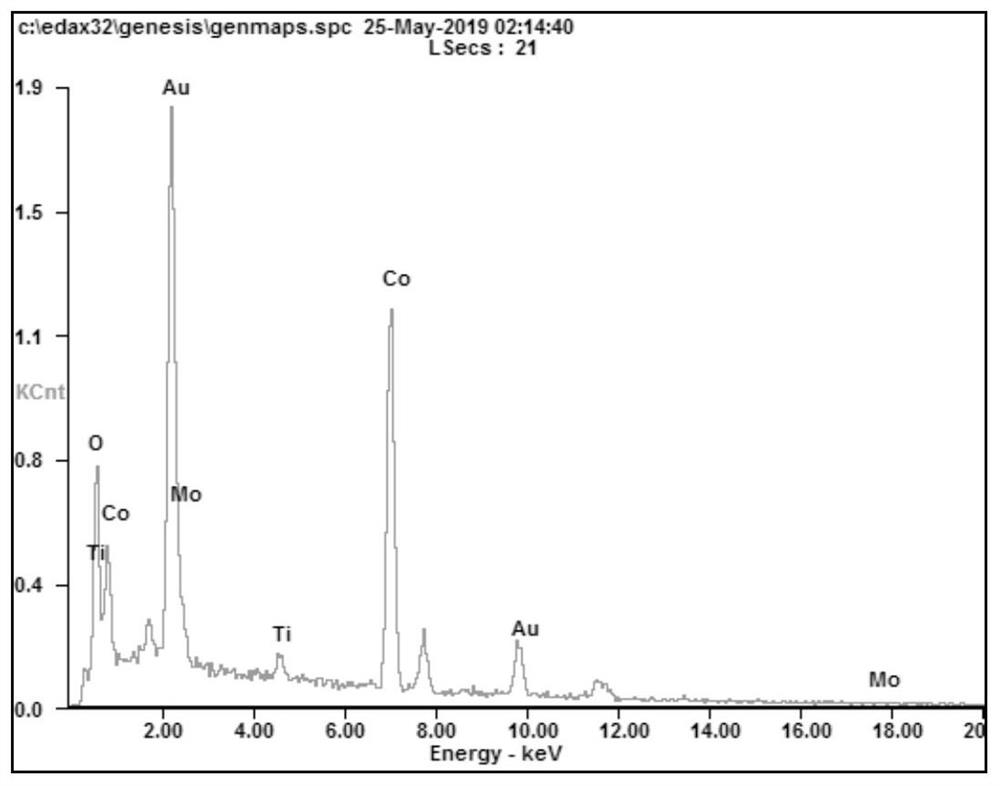

[0052] Embodiment 1: prepare Ti / CoMoO with the method provided by the present invention 4 nanoarray electrodes

[0053] S1. Pretreatment of the porous titanium substrate: use sandpaper to polish the surface of the porous titanium substrate (5cm×5mm×1mm, with a pore size of 10 μm), put it into acetone and ultrasonically soak it to remove oil; then put it into 10% oxalic acid solution Heat and soak for 10 minutes to remove the oxide film on the surface; ultrasonically clean with ultrapure water and ethanol and dry for later use.

[0054] Preparation of S2, Ti / Co(OH)F: Co(NO 3 ) 2 .6H 2 O, NH4F, glucose, and hydrazine were dissolved in water at a molar ratio of 1:2.5:5:5, and stirred evenly; the mixed solution was transferred to a reaction kettle, and S1 pretreated porous titanium was stirred with a magnetic stirrer for 20 minutes and then transferred to Put it into an oven at 170°C, and react for 5 hours; after cooling, take out the titanium sheet, wash it with water, and dr...

Embodiment 2

[0056] Embodiment 2: use Ti / CoMoO provided by the present invention 4 Nanoarray electrodes degrade printing and dyeing wastewater containing rhodamine B.

[0057] Ti / CoMoO prepared under the conditions of Example 1 of the present invention 4 The nanoarray electrode is used as the cathode, the Pt sheet is used as the anode, and 0.1M Na 2 SO 4 As a supporting electrolyte, the constant current mode is used, and the current density is 10mA / em 2 , the distance between the plates is 10mm, and the simulation of degrading rhodamine B containing 10mg / L can remove 98.7% of rhodamine B in 40 minutes, and the effect is shown in Table 1.

[0058] Table 1

[0059] time / min 0 10 20 40 Removal rate 0 56.3 82.5 98.7%

[0060] Compared with prior art, the beneficial effect of this method is:

[0061] 1. Compared with the traditional single metal oxide, the combination of Ti substrate and binary metal oxide greatly improves its electrical conductivity and electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com