Oxygen conveying pipeline for sewage treatment aeration device

An aeration device and sewage treatment technology, applied in water/sewage treatment, water/sewage treatment equipment, water aeration, etc., can solve the problems of concentrated oxygen transportation, easy blockage of openings on pipes, low utilization rate, etc. Small possibility, the effect of improving oxygen utilization rate and expanding the delivery range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

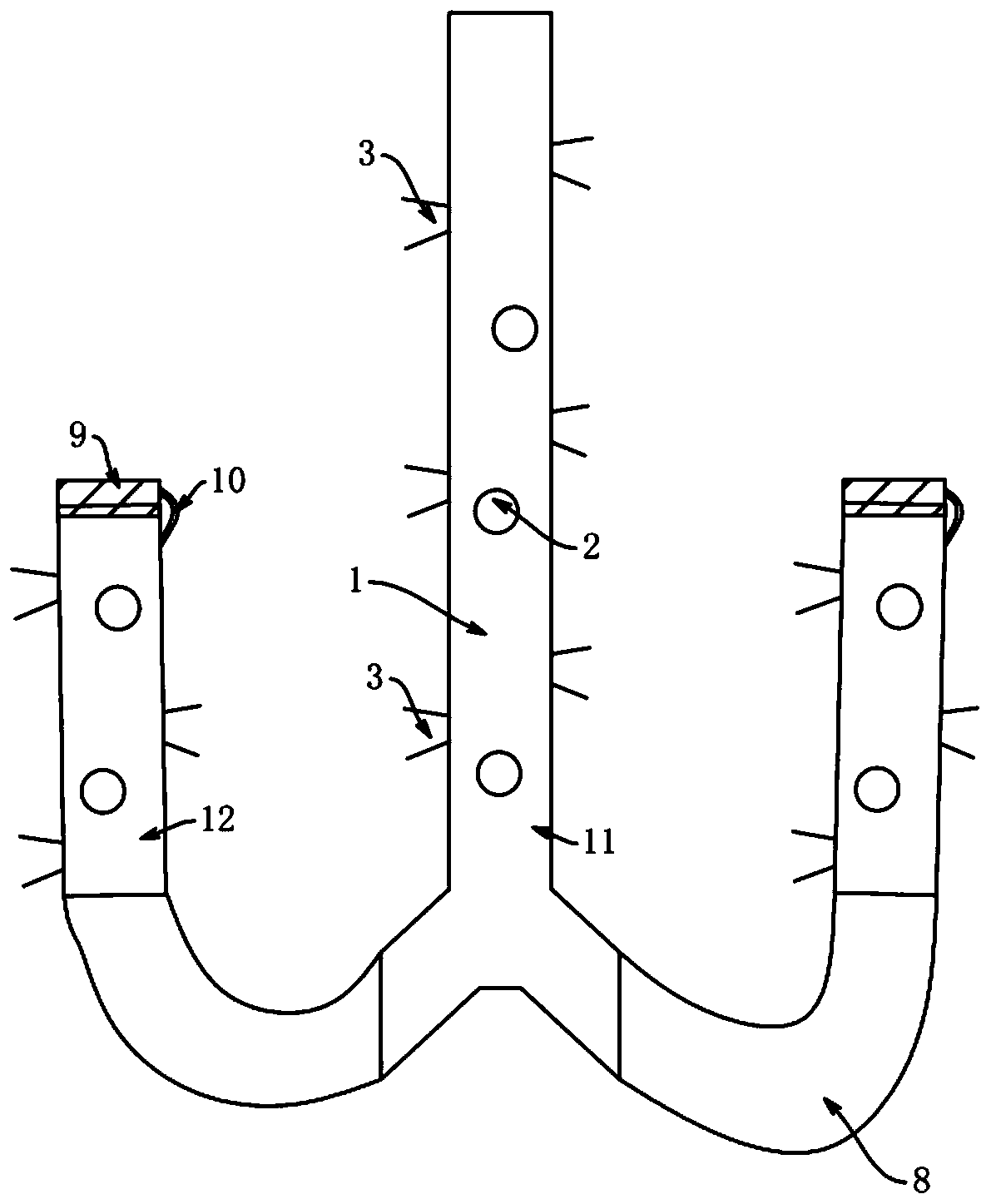

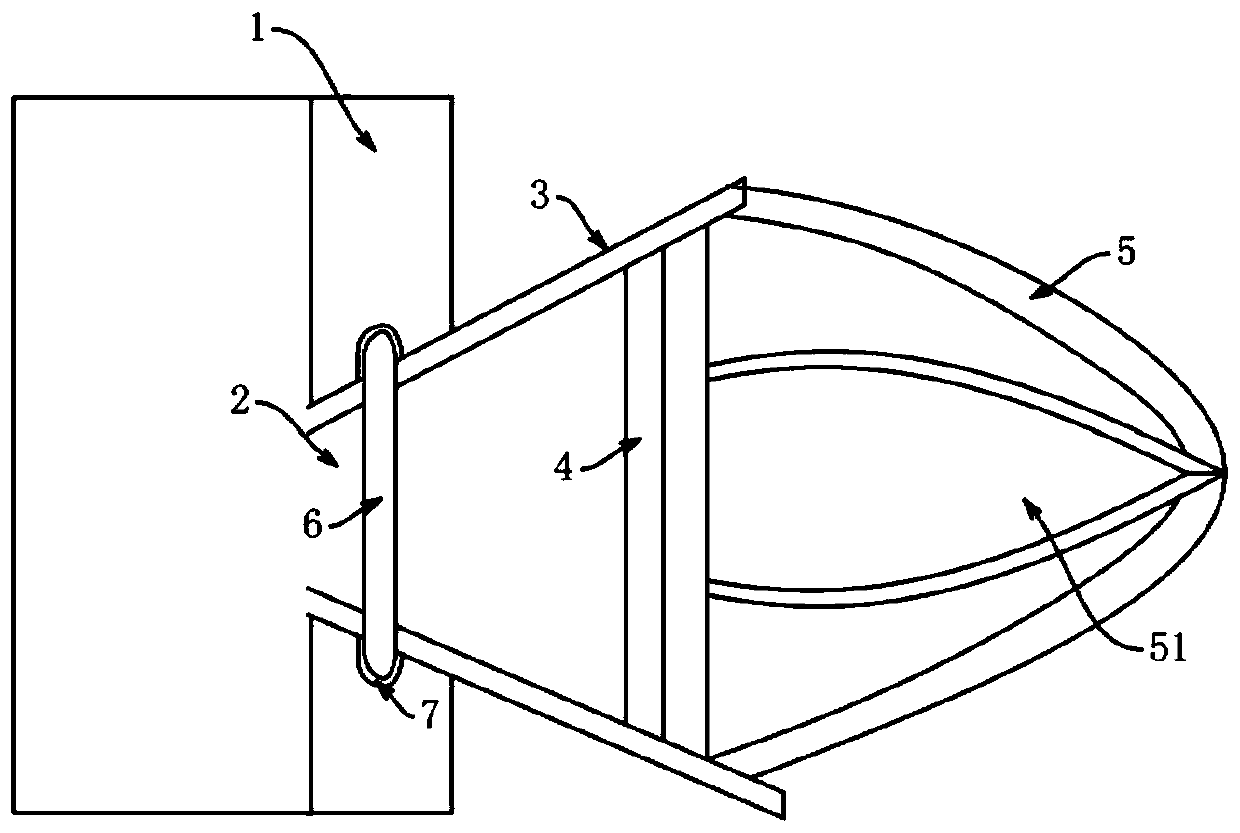

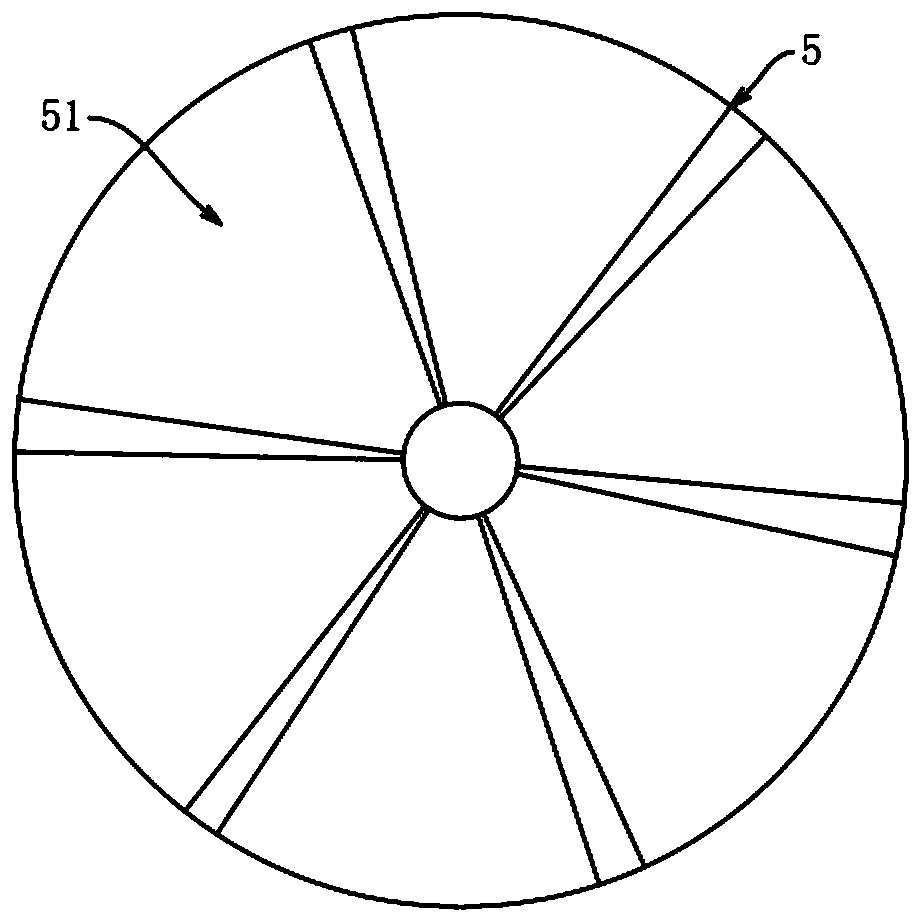

[0017] Embodiment one: by Figure 1 to Figure 4 It is given that the oxygen delivery pipe used for the aeration device for sewage treatment includes a pipeline 1 for transporting oxygen. The surface of the pipeline 1 is provided with a plurality of ventilation holes 2, and the gas enters from the opening above the pipeline 1 and passes through each ventilation hole. 2 and the opening below the pipeline 1 enters the liquid and fully contacts with the liquid to improve the utilization rate of oxygen. Each of the vent holes 2 is provided with a connector 3 for communicating the inside of the pipeline 1 with the external liquid, and each of the connectors 3 is in the shape of a circular platform, and the connecting head 3 is made of rubber material. The outer surface of the smaller end face of each connecting head 3 is provided with a sealing gasket and is detachably connected to the air hole 2 through the sealing gasket. The connecting head 3. The diameter of the circle at the sm...

Embodiment 2

[0020] Embodiment 2: In one embodiment, the pipeline 1 includes a main pipe 11 and a plurality of branch pipes 12, the diameter of each branch pipe 12 is consistent with the diameter of the main pipe 11, and the length of the branch pipe 12 is 1 / 2 of the length of the main pipe 11, so The bottom of the main pipe 11 is provided with a plurality of branch ports, the branch ports are in one-to-one correspondence with the branch pipes 12 and are flexibly connected through the U-shaped hose 8, and the branch pipes 12 connected to the branch ports at the bottom of the main pipe 11 Turning, the gas in the branch pipe 12 enters from the bottom of the branch pipe, and is discharged from the opening above the branch pipe 12 and the vent holes provided on the outer wall. The two ends of the U-shaped hose 8 are internally provided with gaskets, and the gaskets and The inner wall of the U-shaped hose 8 is glued, and the surface of the sealing pad is provided with oblique strip-shaped anti-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com