Structure and method for monitoring hydraulic tunnel dynamic water pressure based on velocity head correction

A technology of flow rate head and hydraulic tunnel, which is applied in hydraulic engineering, measurement of fluid pressure, simultaneous measurement of multiple hydraulic valves, etc. It can solve the deviation of tunnel operation management guidance, cannot reflect the tunnel hydraulic load, and cannot reflect the system flow rate and head, etc. problem, to achieve the effect of facilitating promotion and application, uploading in real time, and improving monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

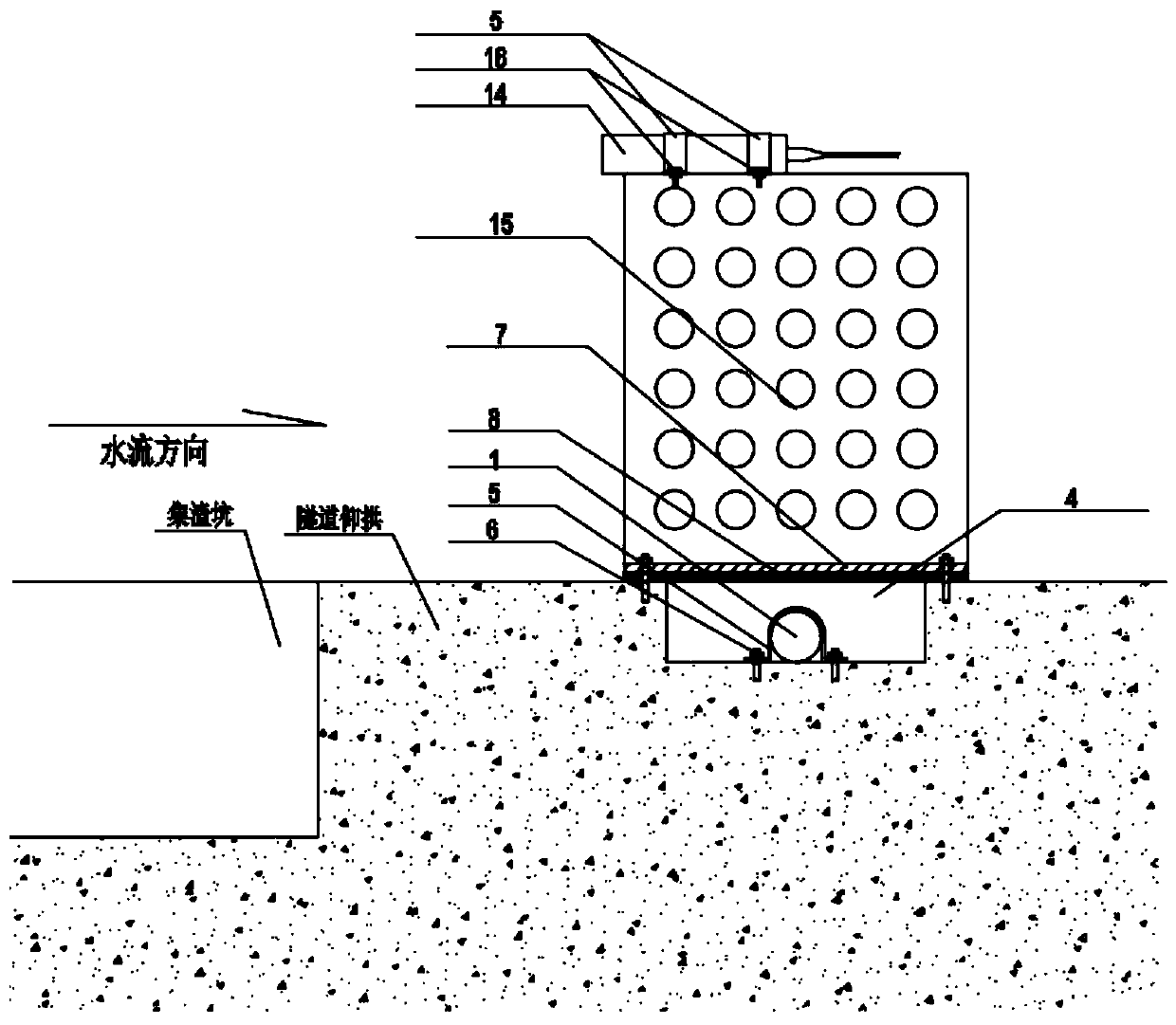

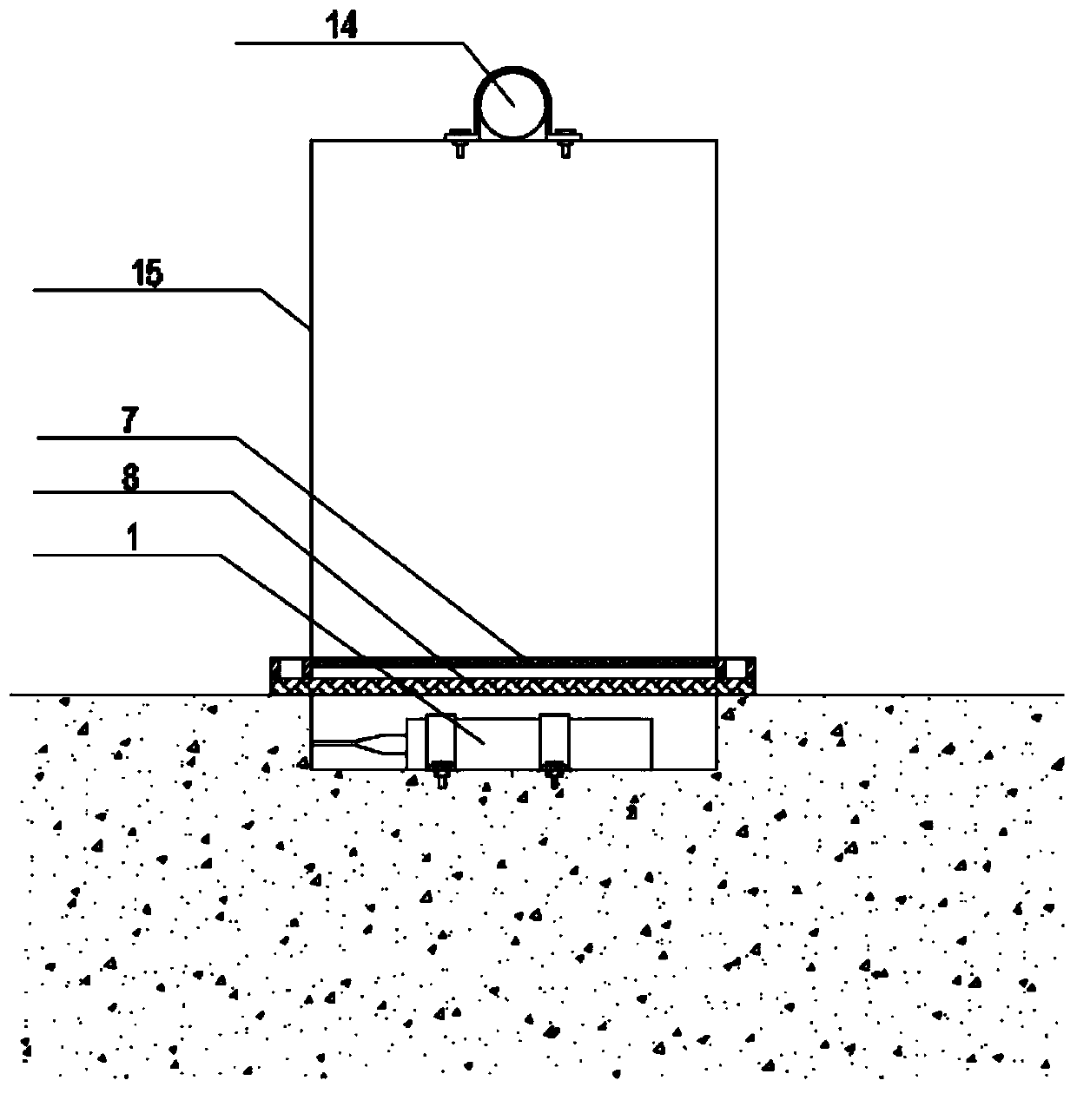

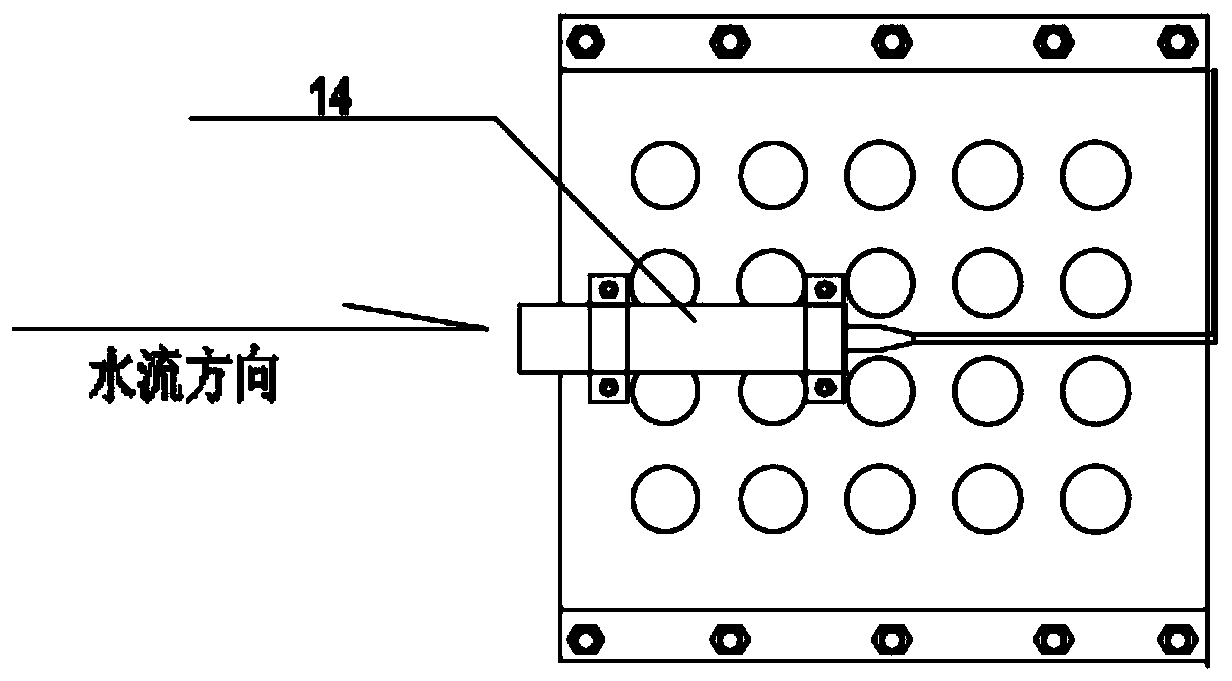

[0047] Such as figure 1 , figure 2 As shown, the hydraulic tunnel dynamic water pressure monitoring structure based on flow rate and head correction provided by the present invention includes a hydrostatic pressure sensor 1, a total water pressure sensor 14, a high-speed fiber grating demodulator 2, a hydrostatic pressure sensor 1 and a total water pressure sensor 14 are respectively connected to the high-speed fiber grating demodulator through the fiber pigtail cable 3. The hydrostatic pressure sensor 1 is installed in the tunnel cavity 4, such as figure 2 , image 3 , Figure 4 As shown, the hydrostatic pressure sensor 1 is fixed at the bottom of the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com