Vertical wall body pouring construction method and pouring construction device

A construction method and technology of construction devices, which are applied to walls, buildings, artificial islands, etc., can solve problems such as non-conformity of anti-seepage capabilities, and achieve the effects of conforming anti-seepage performance, compact structure, and reduced blanking height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

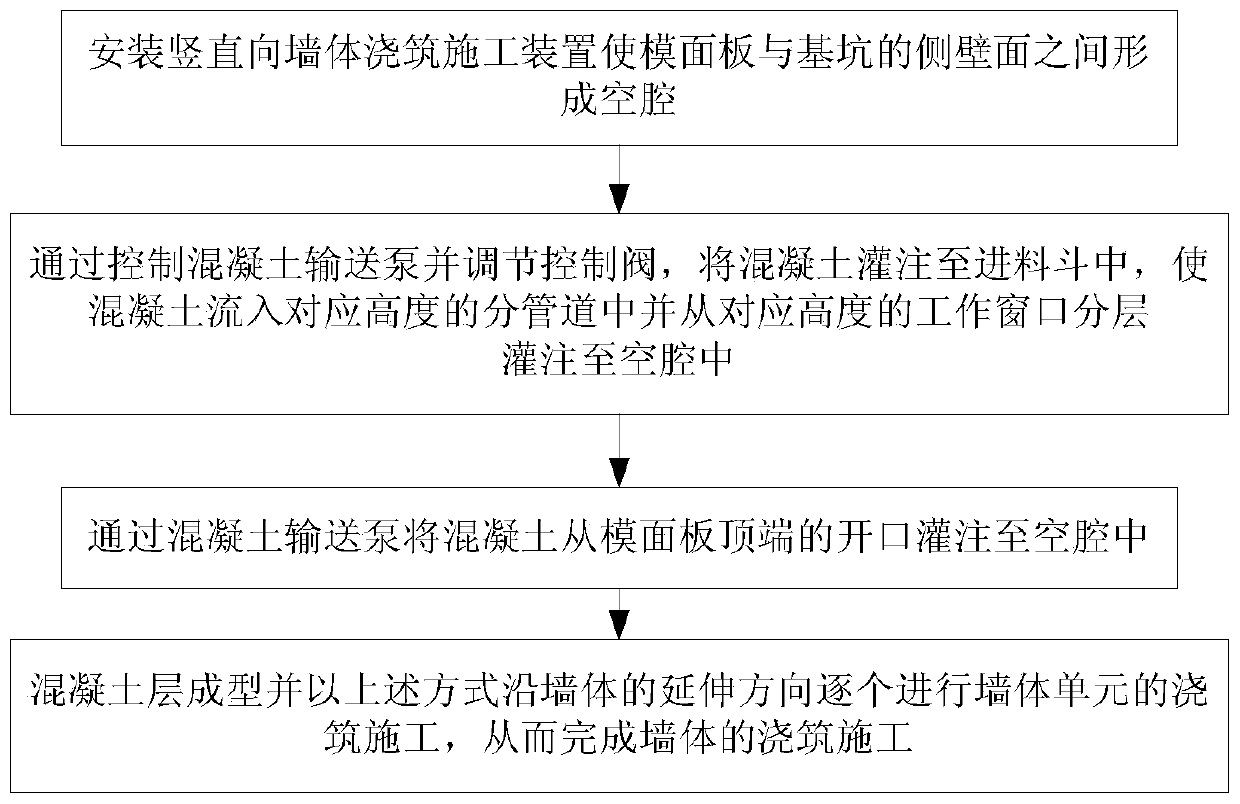

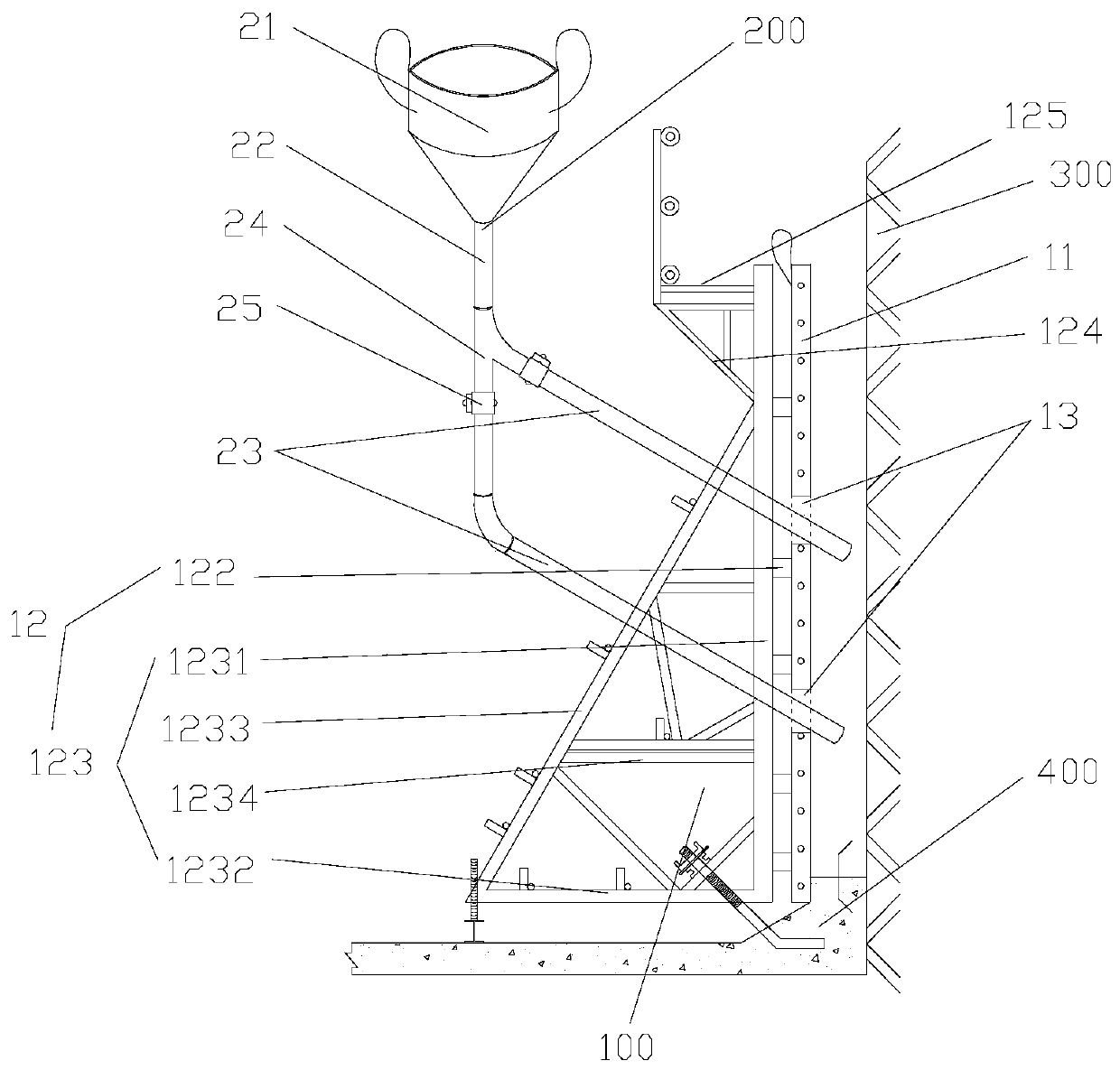

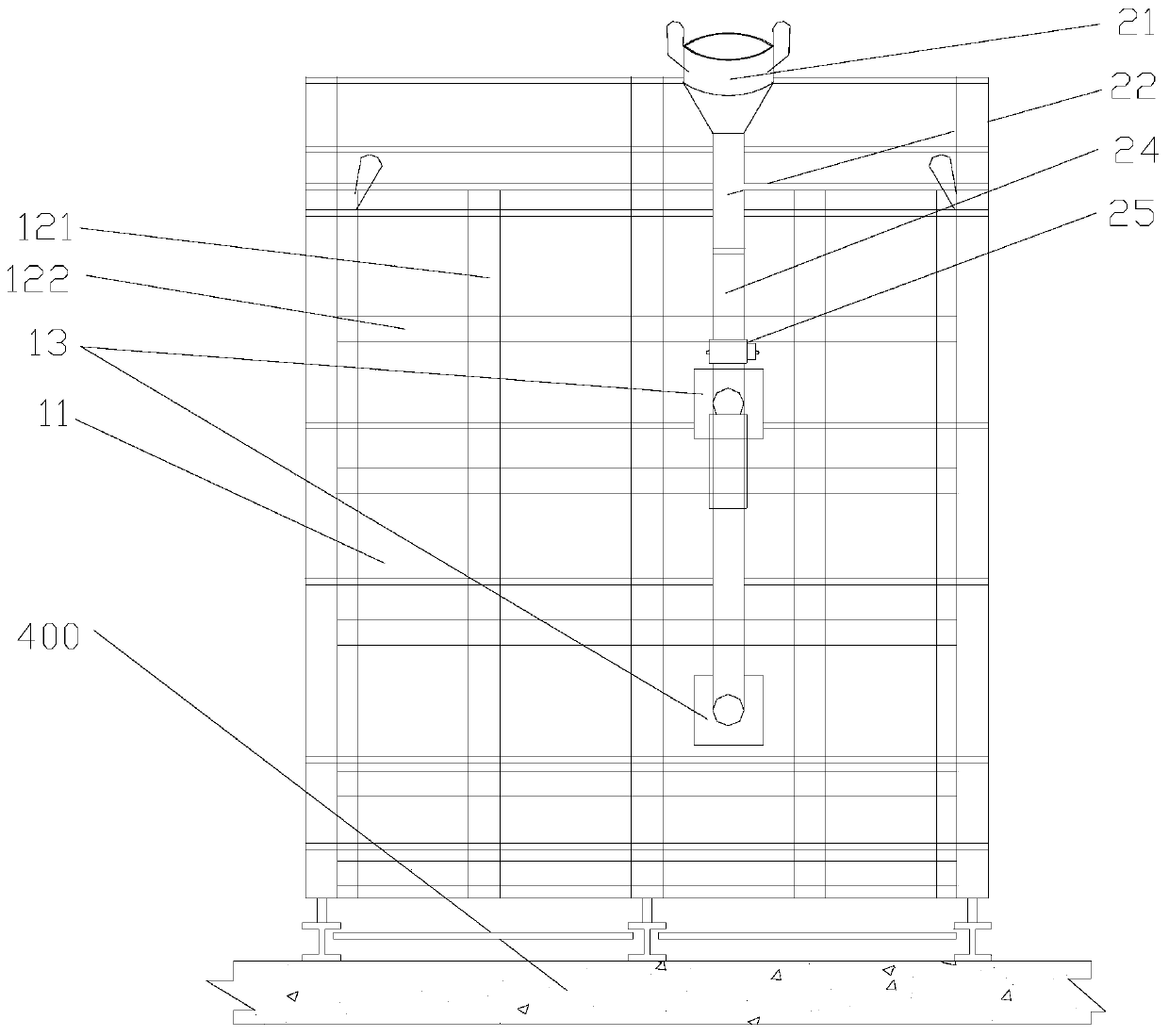

[0027] figure 1 It is a block diagram of the vertical wall pouring construction method of the preferred embodiment of the present invention; figure 2 It is a side view structural schematic diagram of the vertical wall pouring construction device of the preferred embodiment of the present invention; image 3 It is a front view structural schematic diagram of a vertical wall pouring construction device in a preferred embodiment of the present invention; Figure 4 It is a structural schematic diagram of the closing of the working window and door of the vertical window formwork device in the preferred embodiment of the present invention; Figure 5 It is a structural schematic diagram of the opening of the working window of the vertical window formwork device in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com