Lifting type operation platform of elevator shaft

An operation platform and lifting technology, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of easy tilting and deformation of the operation platform, large gap between the platform and the hoistway wall, and time-consuming, etc., to achieve Improve the efficiency of erection, improve the safety performance of use, and reduce the effect of using materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

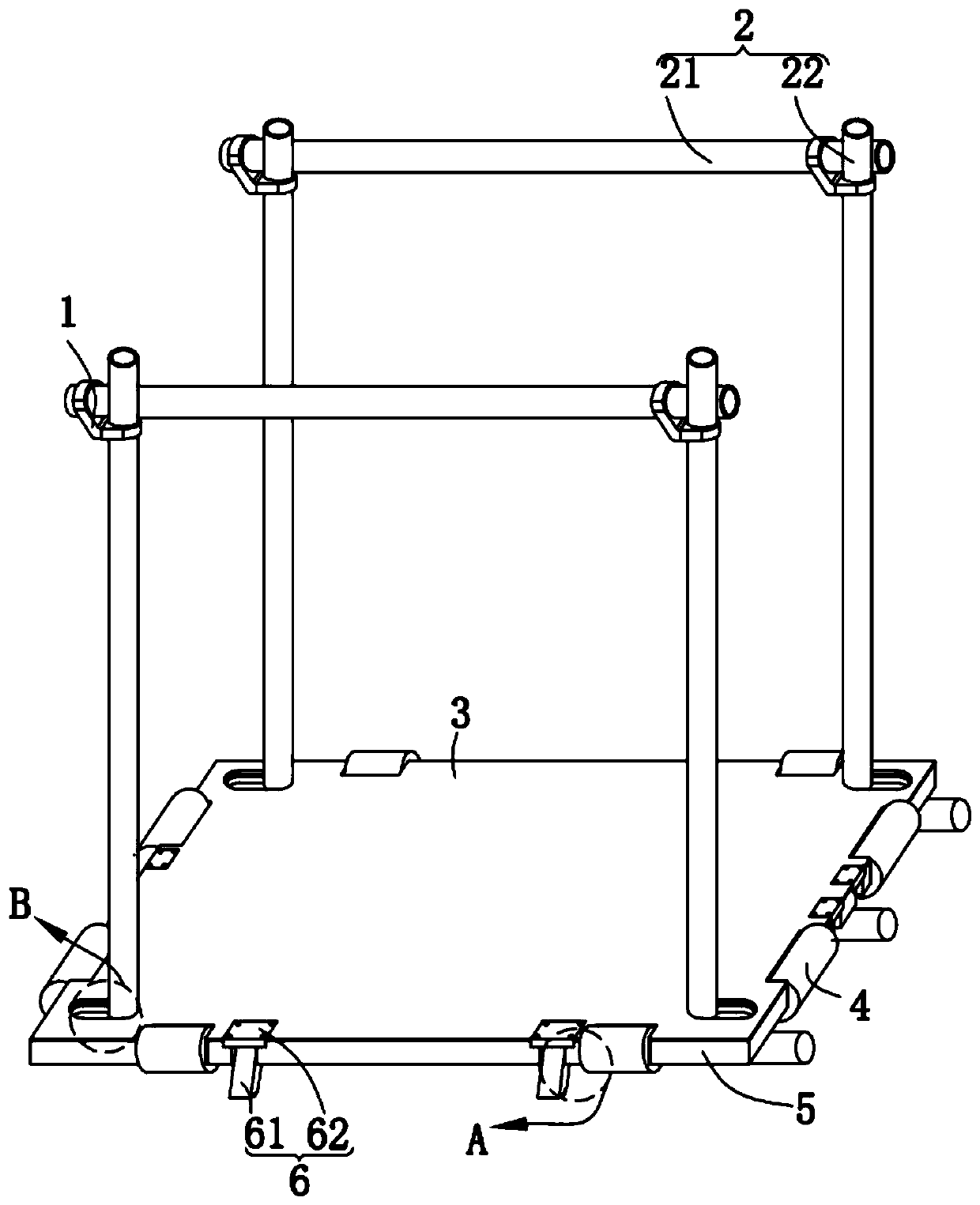

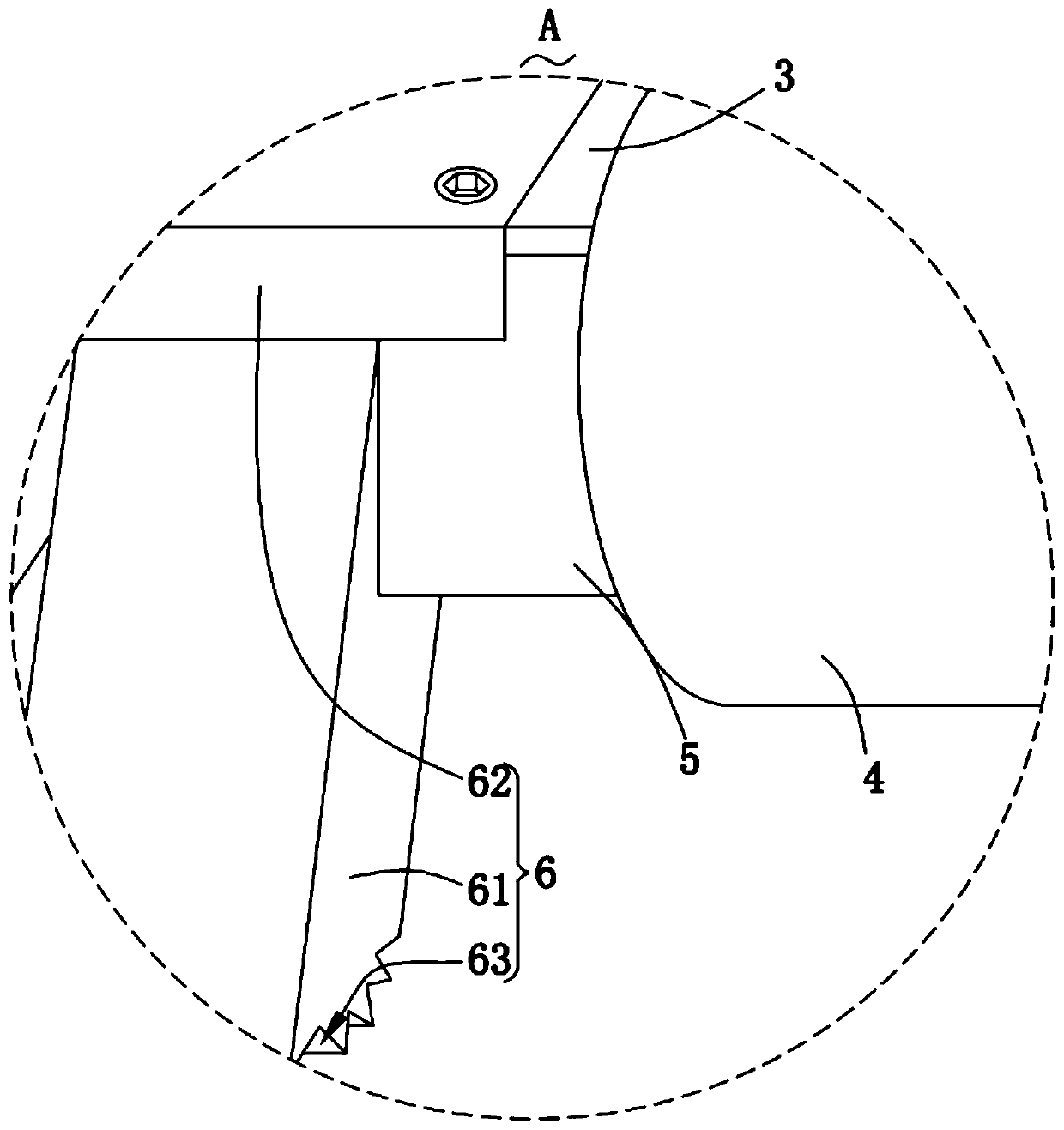

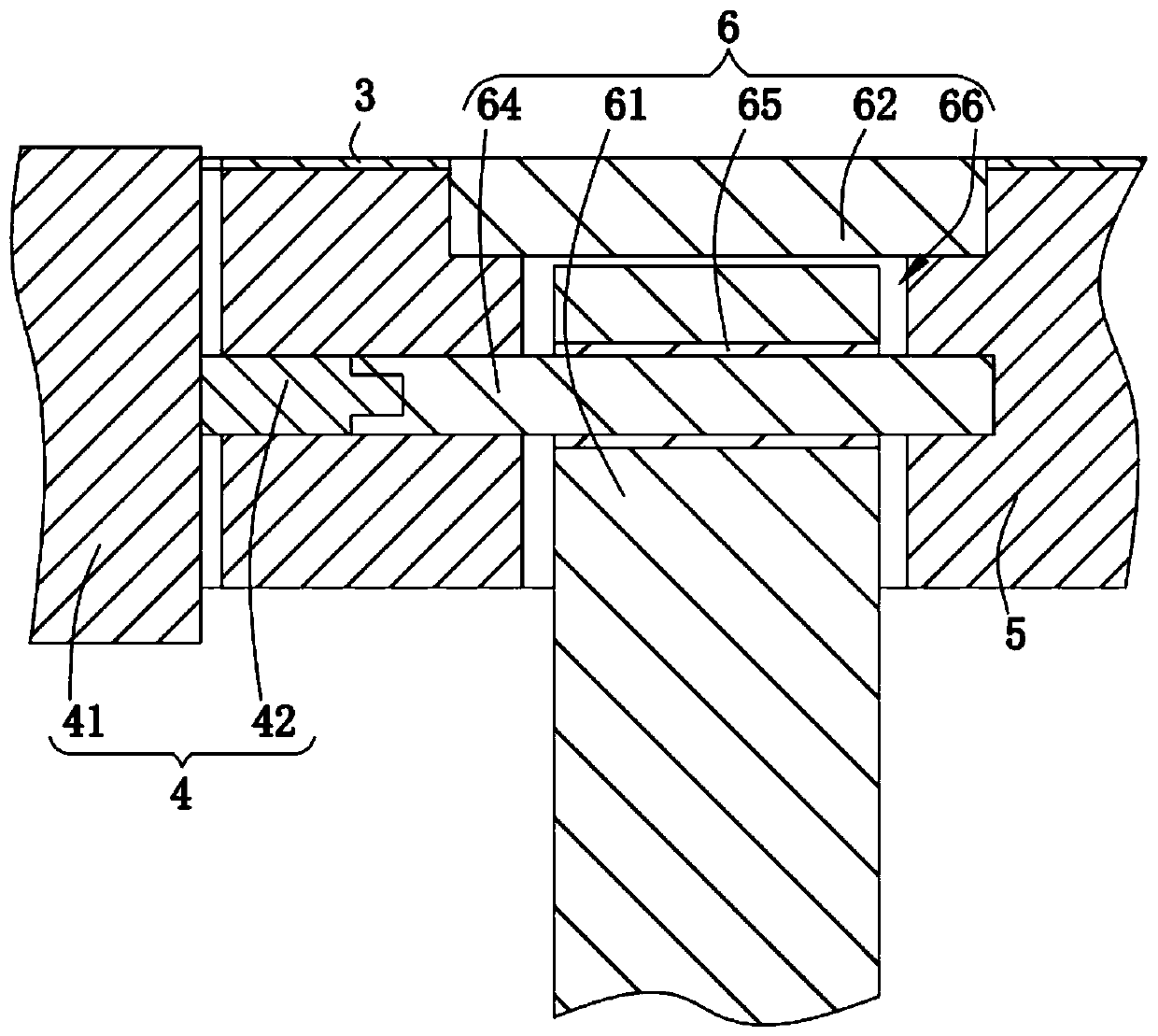

[0022] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1 A schematic structural view of a preferred embodiment of the elevator shaft lifting operating platform provided by the present invention; figure 2 for figure 1 The enlarged schematic diagram of part A shown; image 3 for figure 2 The schematic diagram of the connection structure between the outer frame and the limit structure shown; Figure 4 for figure 1 The enlarged schematic diagram of part B shown; Figure 5 for image 3 The schematic diagram of the connection structure between the outer frame and the guide wheel is shown. The lifting operation platform of the elevator shaft includes: an outer frame 5; a steel plate 3, the square steel plate 3 used to carry construction materials is welded to the outer frame 5 of a square structure; an instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com