Hydraulic shaping pipe column and casing pipe shaping process

A hydraulic and pipe string technology, which is applied in the field of repairing damaged casing, can solve the problems that the pipe string cannot be lifted up due to being stuck easily, and the pipe string cannot be lifted up, etc., and achieves the effect of simple and easy structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

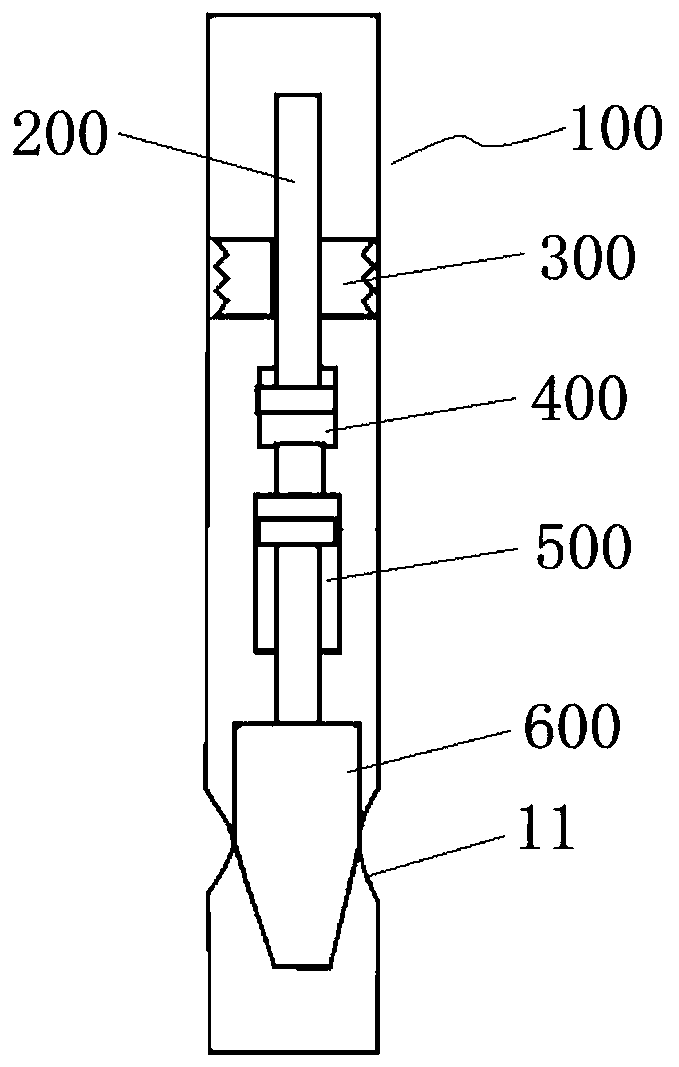

[0046] Specific embodiment 1 of the hydraulic shaping string of the present invention, such as Figure 1 to Figure 10 shown. The hydraulic shaping pipe string of the present invention can carry out external expansion and shaping on the casing deformed section in the casing, and can lift the pipe string after the shaping is completed.

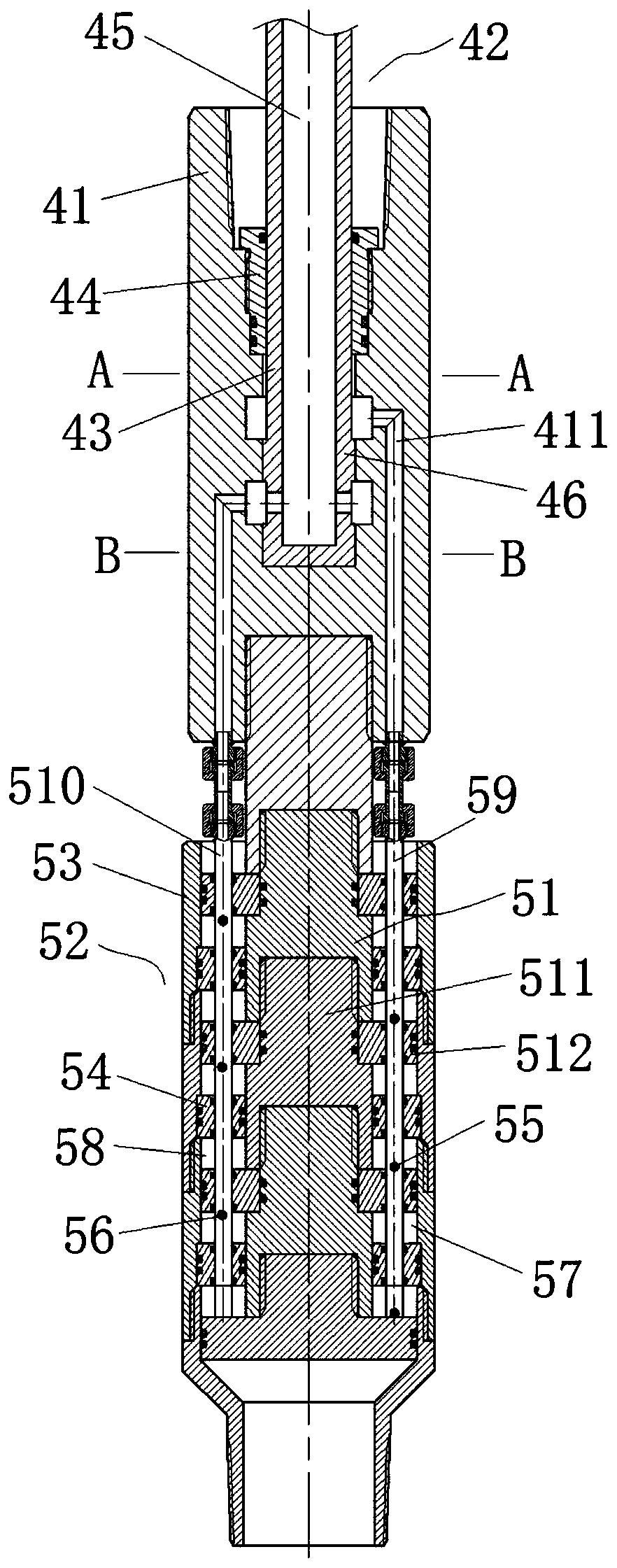

[0047] The hydraulic shaping string includes an oil pipe 200 , a hydraulic anchor 300 , a hydraulic commutator 400 , a two-way booster 500 and a shaper 600 which are threaded in sequence from top to bottom.

[0048] The oil pipe 200 is an ordinary oil pipe common in the market, with a central channel in the middle.

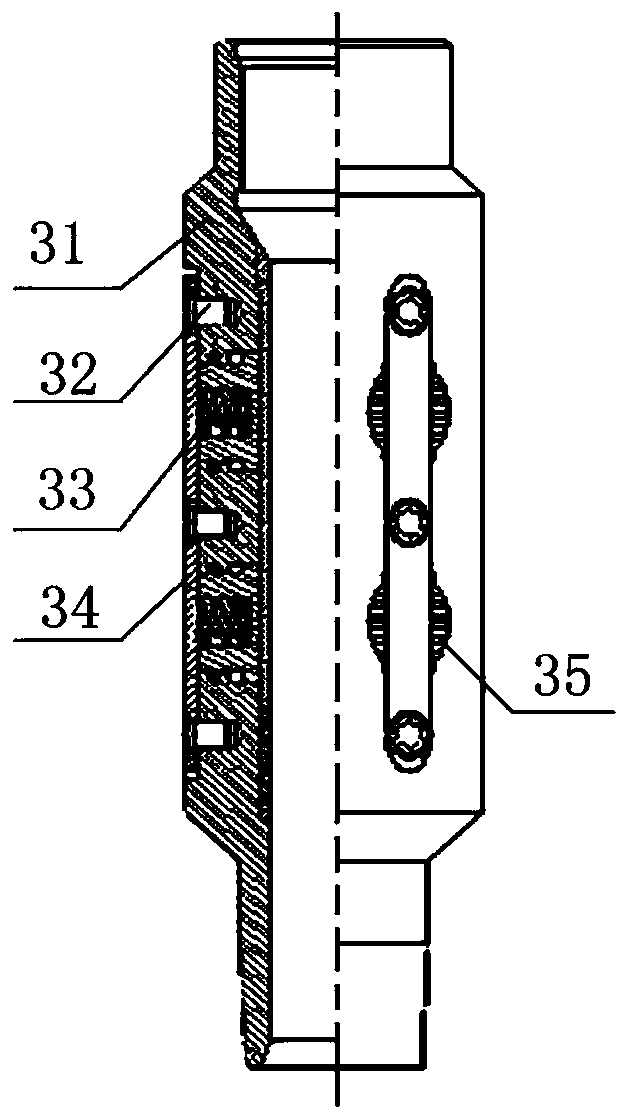

[0049] The structure of the hydraulic anchor 300 is as figure 2 As shown, the hydraulic anchor 300 includes an anchor body 31 with a central channel communicating with the oil pipe 200 in the middle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com