Garment dryer for textile production

A drying machine and garment technology, applied in the field of textile production, can solve the problems of reducing drying efficiency, increasing energy consumption, polluting the environment, etc., and achieving the effects of increasing the range, increasing drying efficiency, and uniform heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

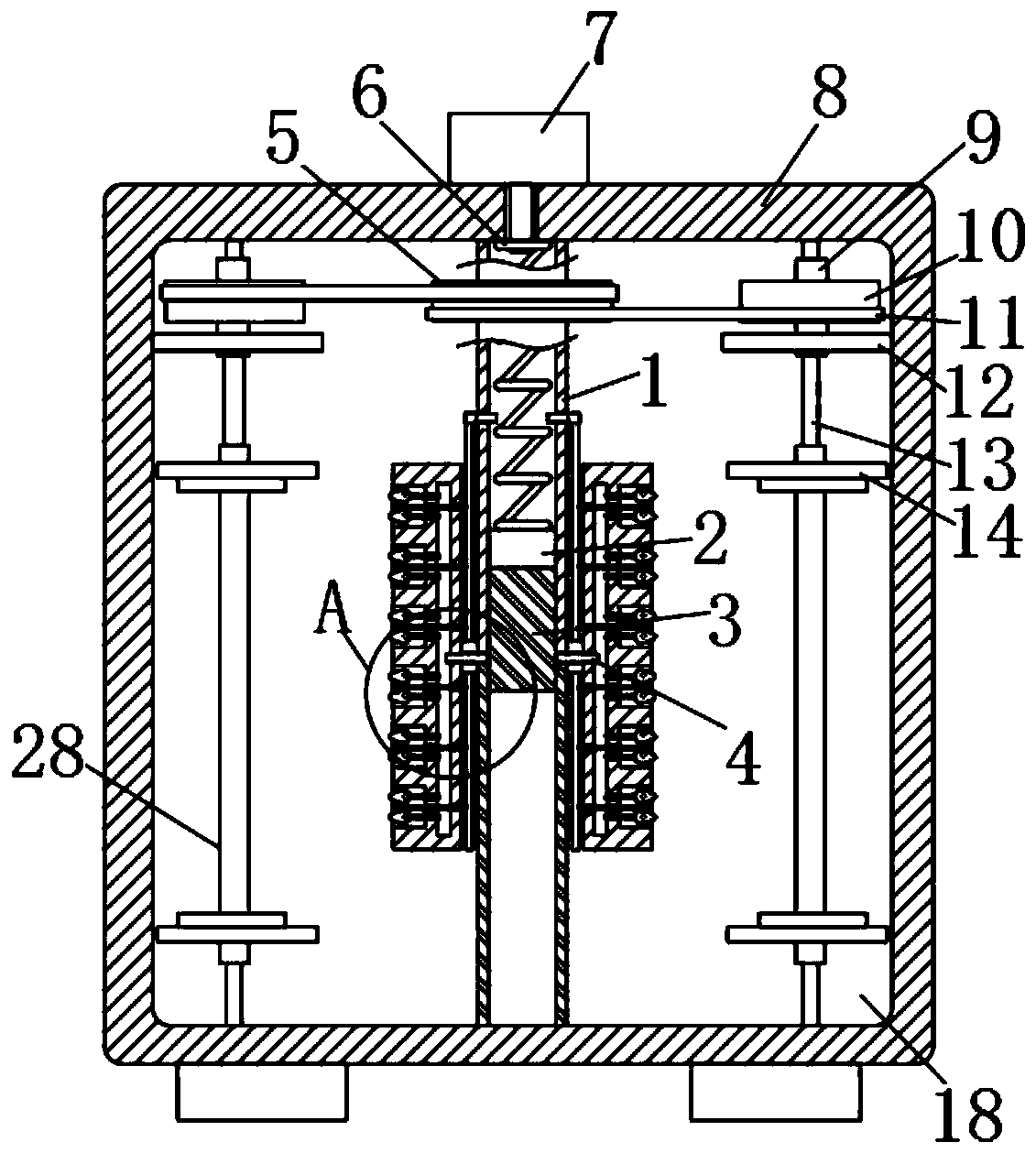

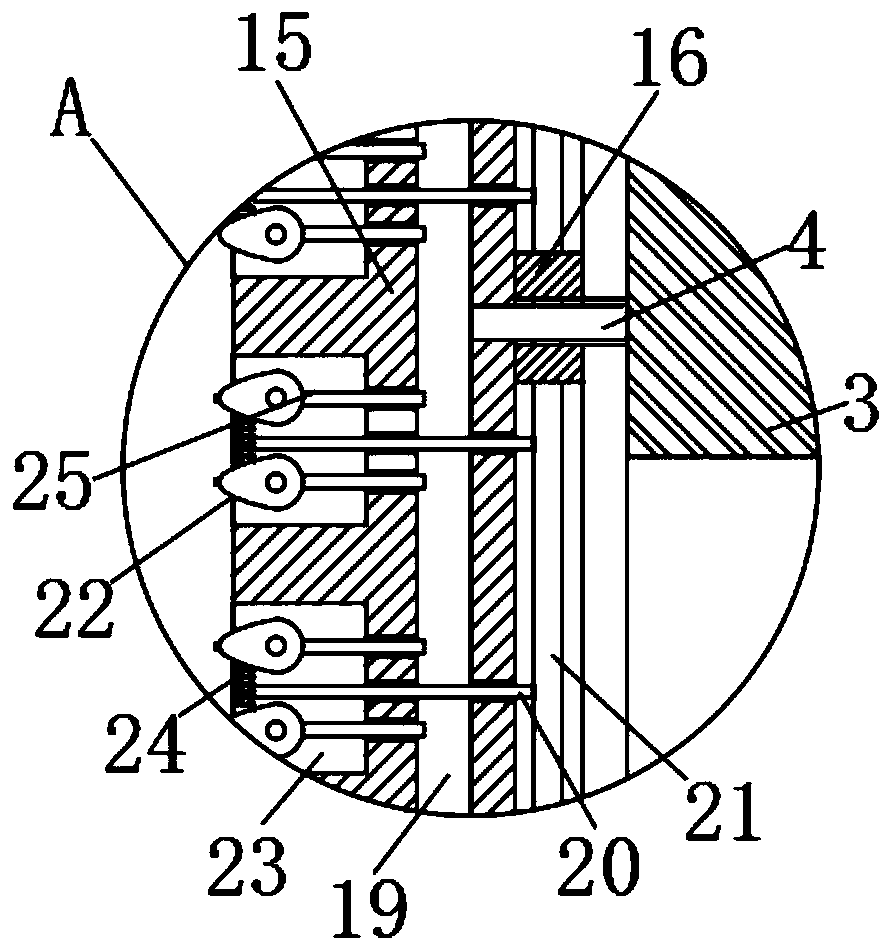

[0023] refer to Figure 1-3 , a garment dryer for textile production, comprising a drying box 8, the drying box 8 is provided with a casing 1 vertically rotatably connected to the inner wall of the drying box 8, and a piston is arranged in the upper half of the casing 1 2. The upper end of the piston 2 is elastically connected to the inner top of the sleeve 1 through the first spring 6, the lower end of the piston 2 is fixedly connected with the threaded block 3, and the inner wall of the lower half of the sleeve 1 is provided with a thread that matches the threaded block 3 Two connecting blocks 16 are fixedly connected symmetrically to both sides of the sleeve pipe 1, and the opposite sides of the two connecting blocks 16 are fixedly connected with a device bar 15, and the device bar 15 is provided with an air chamber 19, and one part of the device bar 15 A plurality of square grooves 23 are arranged at equal intervals on the side, and two nozzles 22 are rotatably connected i...

Embodiment 2

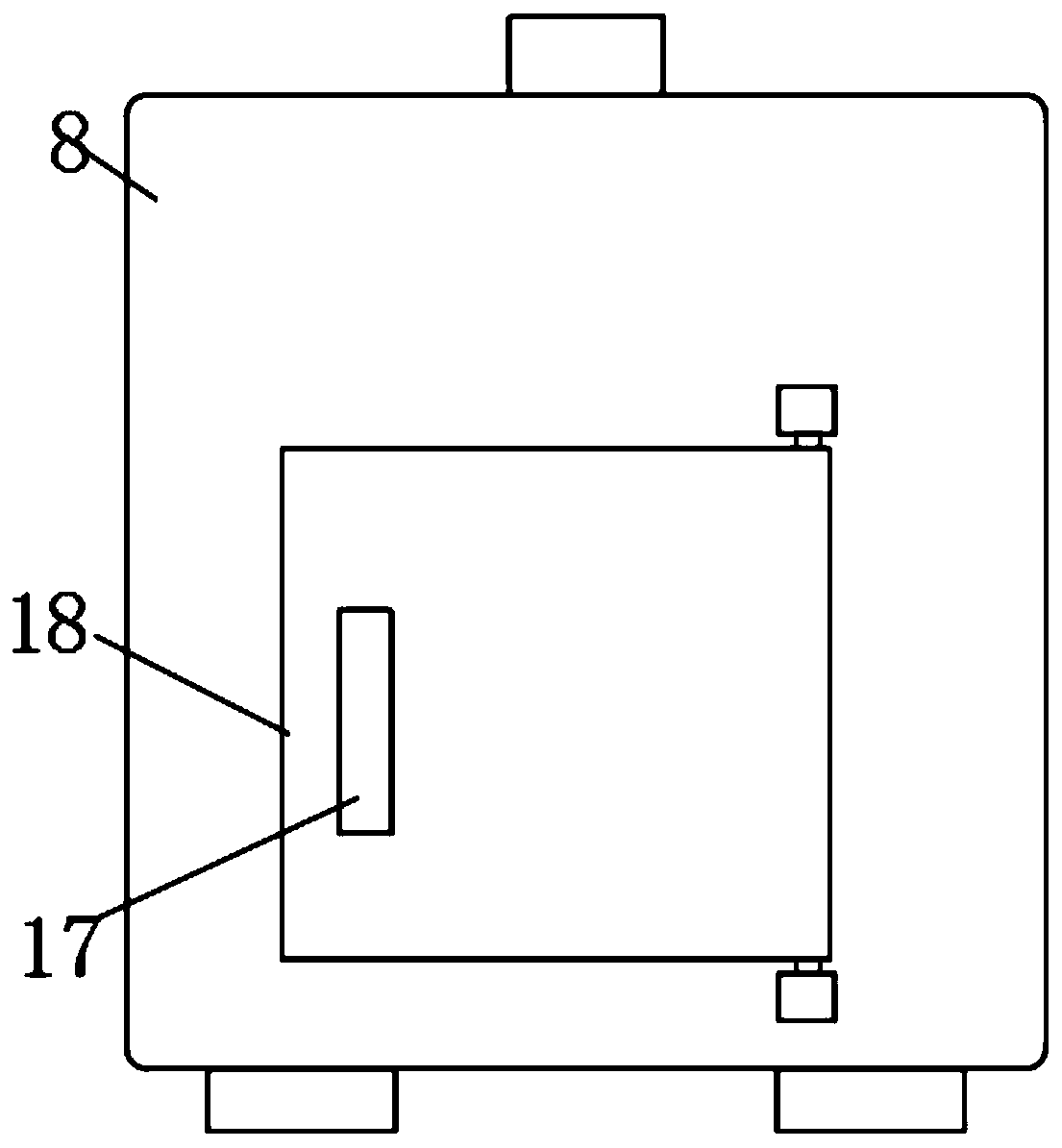

[0027] refer to Figure 4-6, the difference between this embodiment and Embodiment 1 is that the relative inner walls of the drying box 8 are fixedly connected with the installation plate 12, the side wall of the first sleeve 9 runs through the installation plate 12, and the inner wall of the second sleeve 28 Fixedly connected with slide bar 27, rotating bar 13 is provided with the chute 26 that matches with slide bar 27, and rotating bar 13 is positioned at mounting plate 12 and clothes hanger 14 and is partially sleeved with so that the first sleeve 9 and the second The second spring 31 elastically connected to the sleeve 28, the upper end of the clothes hanger 14 is fixedly connected with two round head rods 29, and the lower end of the mounting plate 12 is fixedly connected with a plurality of hemispherical blocks matched with the round head rods 29. 30.

[0028] In this embodiment, when there are dripping water droplets on the clothes to be dried, the drying efficiency o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com