Non-destructive detection method and application based on micro-motion three-component spectral ratio vhsr

A non-destructive detection, three-component technology, applied in the field of engineering geophysical detection, can solve the problems of fast signal attenuation, limited detection depth, electromagnetic interference, etc., and achieve the effect of strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

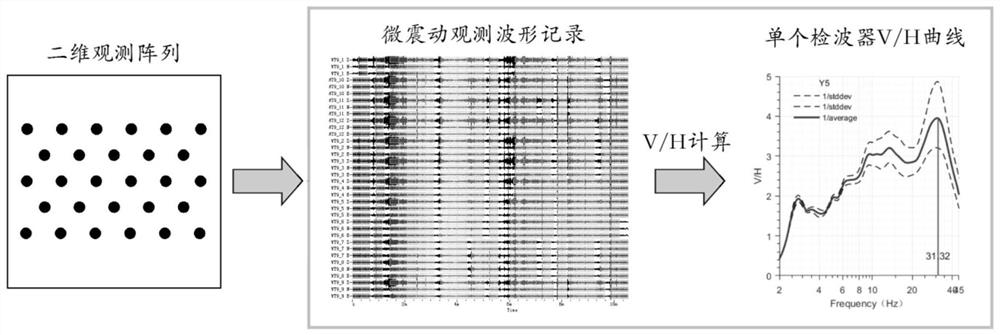

Method used

Image

Examples

Embodiment 1

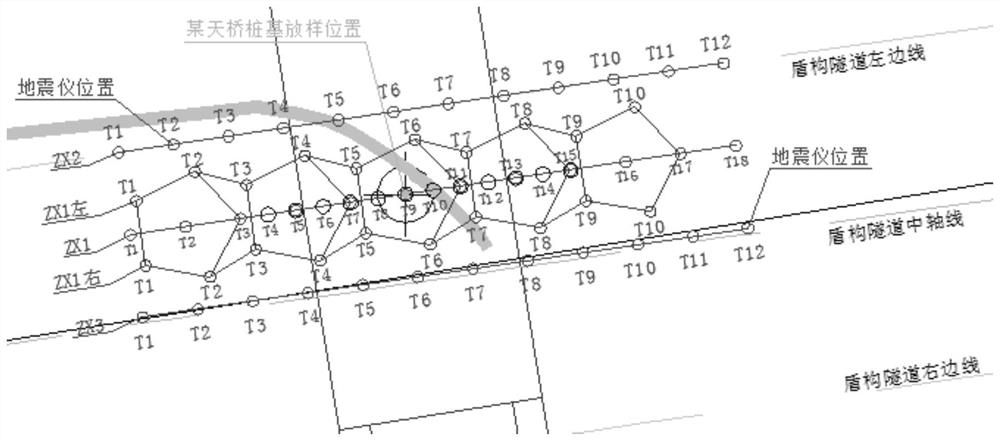

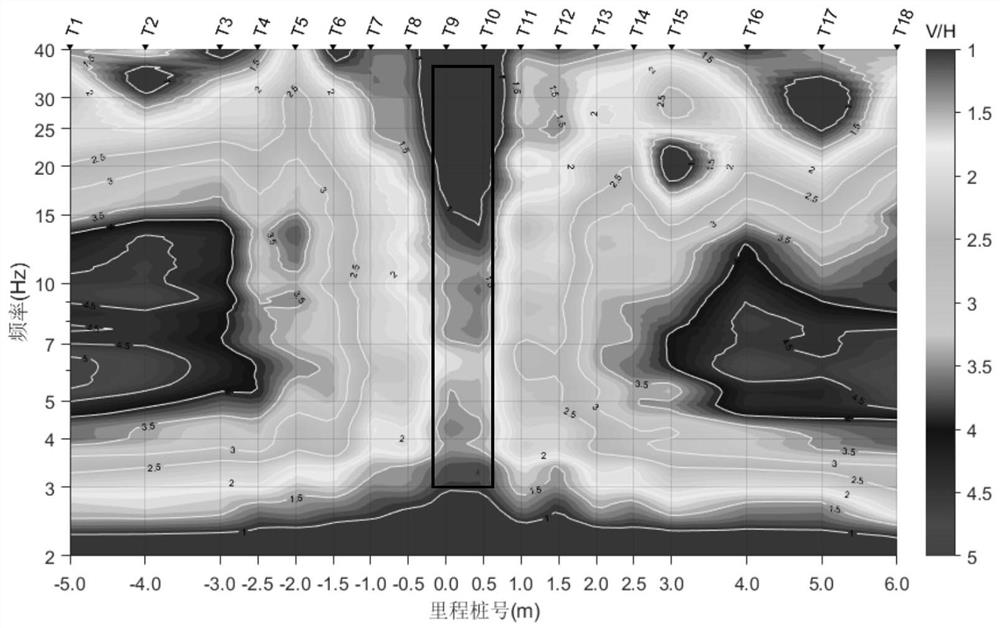

[0056] Example 1: Detection of pile foundation position and pile length in a subway shield section by VHSR method

[0057] Project overview: Obstacle survey data show that the pile foundation of a flyover (the part above the ground has been demolished) in the shield tunnel section of a subway is located within the tunnel body of the shield tunnel, but there are doubts, so the VHSR method is used to detect and find out. The bedrock surface was not revealed at the end hole 47.8m of the nearby detailed survey drilling hole MDZ3-29-34, and the main soil layers from top to bottom are miscellaneous fill, silty clay, silt, silty clay, silt, silty clay, sandy soil Strongly weathered granite.

[0058] Step 1: This VHSR method detection uses a three-component high-precision integrated digital seismograph, and arranges two-dimensional three-component geophone arrays at intervals of 0.5 to 1.5 m (see figure 2 ), collect surface micro-vibration signals for 10-15 minutes;

[0059] Step 2...

Embodiment 2

[0064] Example 2: VHSR method detection of artificial rockfill range in the range of foundation pit support in a construction site

[0065] Project overview: The survey data reveals the distribution characteristics of the main rock and soil layers in the survey area as follows: (1) Miscellaneous fill (local silty clay), silt (soil) mixed with sand, silt, silty clay, silt (soil) , silty clay, round breccia, crushed pebbles, silty soil, sandy strongly weathered, fragmented strongly weathered and moderately weathered tuff, etc. The bedrock is buried at a depth of about 45m. The planned road is on the edge of the survey area. During construction, local rock filling may invade the construction range of the foundation pit support and enclosure piles, which will affect the later construction of the foundation pit support and enclosure piles. Unfavorable geological bodies such as rockfill that may exist within the pile construction range are detected by the non-destructive VHSR method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com