Capacitor pull lead assembling mechanism

An assembly mechanism and lead-pulling technology, used in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of core package short circuit, breakdown, and large resistance of core package reinforcement ribs 14, and achieve the effect of ensuring distance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

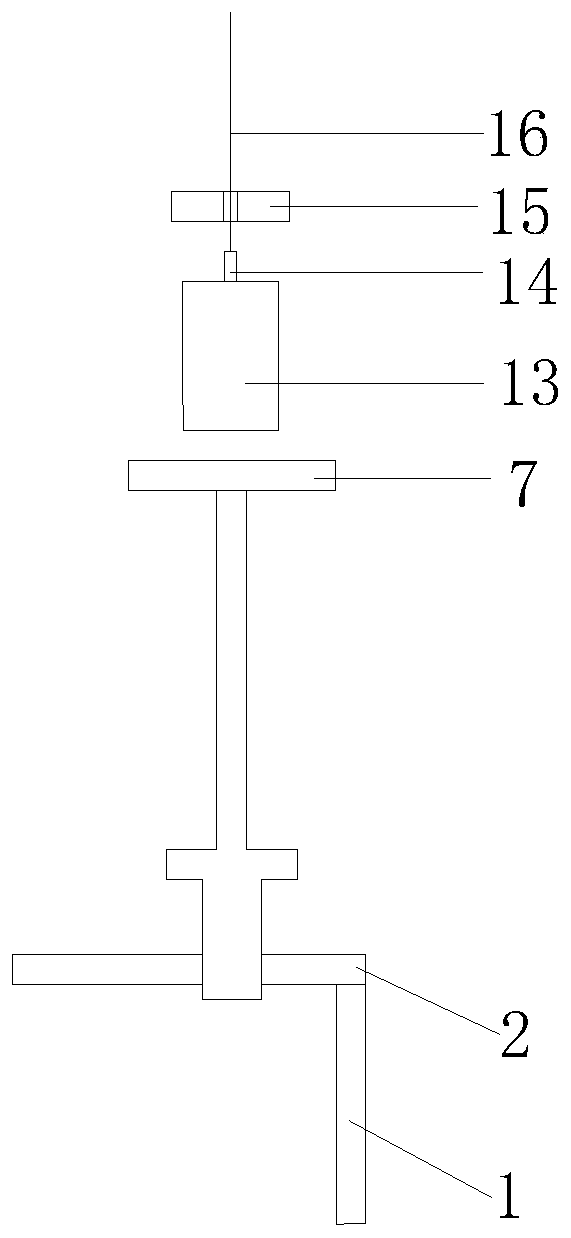

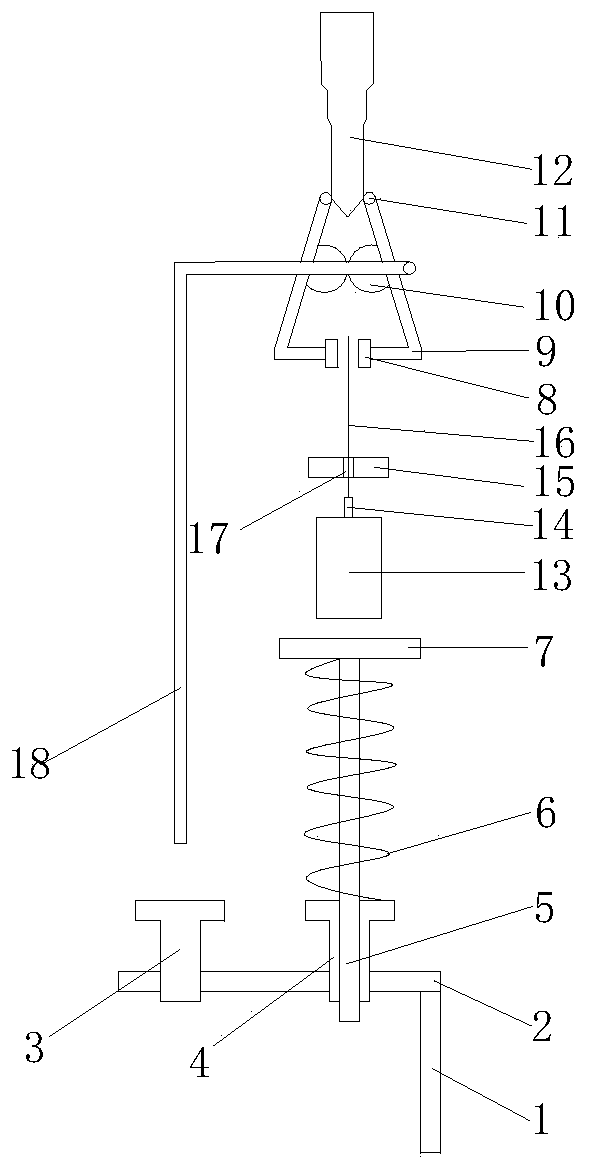

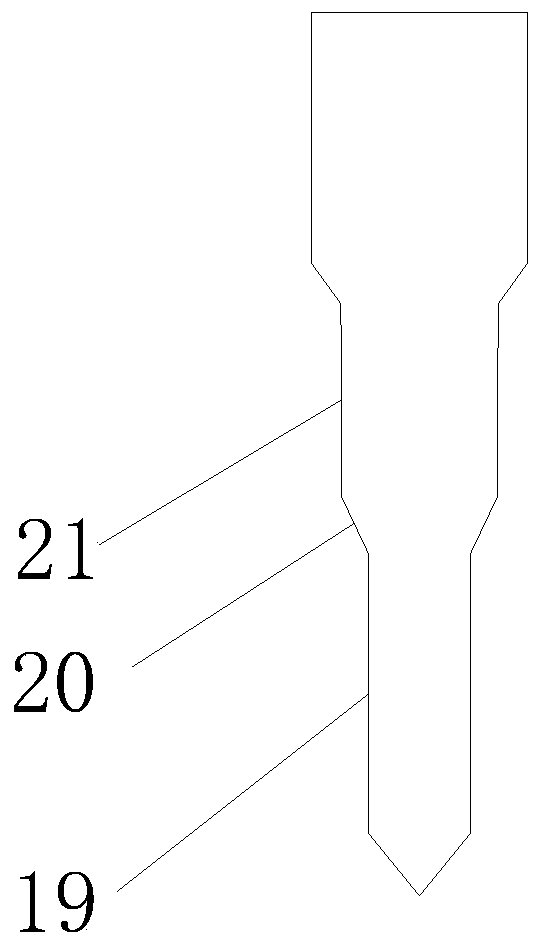

[0015] As shown in the figure, a capacitor pulling lead assembly mechanism includes a clamping mechanism for clamping the pulling lead 16, the clamping mechanism is located above the capacitor core package 13, and also includes a clamping mechanism for driving the Lifting device that moves the clamping mechanism up and down. The lifting device is a push rod 1, and a top plate 2 is arranged above the push rod 1, and the top plate 2 is connected with a clamping device through a transmission device.

[0016] An adjusting bolt 3 is fixed on the top plate 2 , the transmission device is a connecting rod 18 , and the adjusting bolt 3 corresponds to the connecting rod 18 . A sleeve 4 is also provided on the top plate 2, and a slide bar 5 is slid inside the sleeve 4, and the upper part of the slide bar 5 is connected with a tray 7, and the tray 7 is used to withstand the capacitor core package 13 A spring 6 is sheathed on the slide bar 5 , one end of the spring 6 is fixed on the tray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com