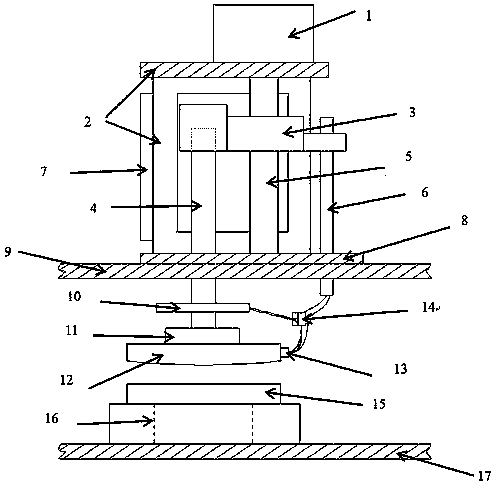

Single-servo forming station structure of 3D hot bending machine

A hot bending machine, 3D technology, applied in glass forming, glass reshaping, manufacturing tools, etc., can solve the problems of low control precision, poor surface level of heating plate, poor stability, etc., to achieve high control precision and guarantee Consistency, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] to combine figure 1 , the present invention is an important part of the furnace cavity structure, and the whole structure runs through the upper box plate of the furnace cavity to the bottom plate of the furnace cavity. From top to bottom, in this embodiment, the servo motor 1 is supported by the gantry bracket 2 , the lower end of the servo motor is connected to the lead screw 5 , and the main shaft 4 is connected to the lead screw and the outlet pipe 6 through the connector 3 . The grating ruler device 7 is installed on the side of the gantry support, and the main shaft and the outlet pipe pass through the base backing plate 8 and the upper box plate 9 of the furnace cavity to enter the furnace cavity. The main shaft is connected with the upper heating plate 12 through the flange 11, a plurality of heating tubes 13 are installed in the upper heating plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com