Resistivity Tomography Detector and System Between Horizontal Boreholes

A technology of horizontal drilling and tomography, used in radio wave measurement systems, electrical/magnetic exploration, measurement of resistance/reactance/impedance, etc. The hole wall is in good contact, and the cable is not easy to be inserted into the hole, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

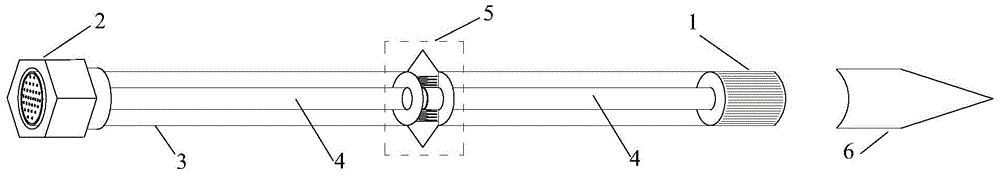

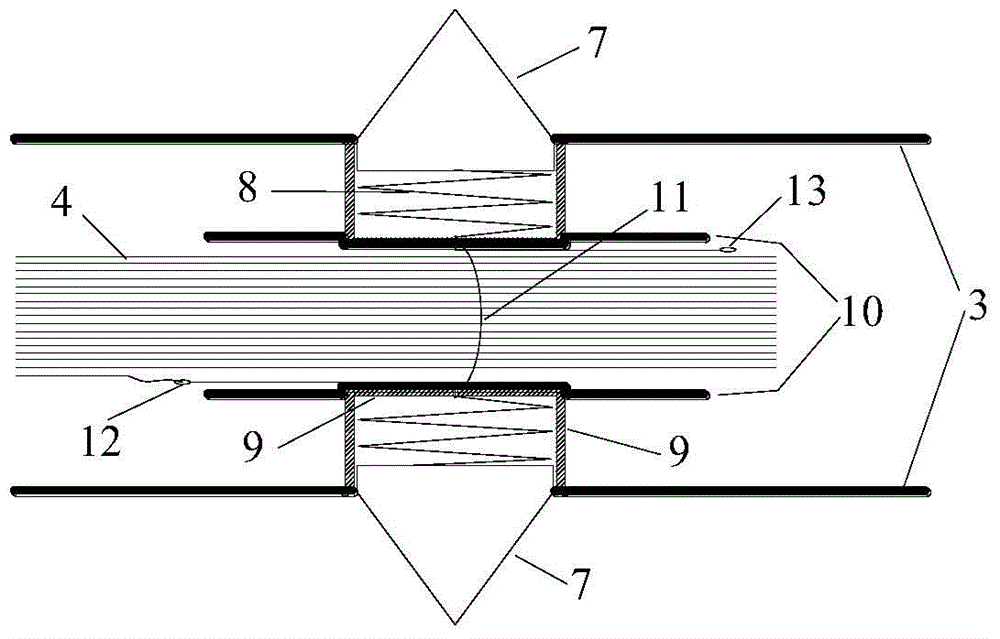

[0047] Example 1: figure 1 It is a structural diagram of a resistivity tomography detector between horizontal boreholes, which mainly consists of a multi-pinhole positive interface 1, a multi-pinhole negative interface 2, an outer casing 3, a multi-core detection cable 4, a hole wall contact device 5 and a sealing Triangular pyramid 6 constitutes. The device as a whole is a linear steel structure, and the interior is completely sealed, solid and firm, ensuring its practical applicability.

[0048] The outer sleeve 3 is a linear internal sealed steel rod-shaped structure, and its two ends are respectively provided with a multi-pinhole positive interface 1 and a multi-pinhole negative interface 2 that can be mated and inserted. The two ends of the steel pipe have multi-pinhole positive and negative interfaces mainly for the interconnection of multiple detectors, which are suitable for detection under different hole depth conditions.

[0049]The sealing triangular cone 6 is ins...

Embodiment 2

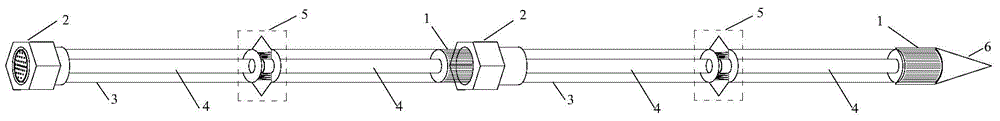

[0058] Embodiment 2: as image 3 , 4 As shown, at least two of the detectors are plugged in series end to end in sequence, a sealed triangular cone 6 is installed on the front end of the most front detector, and the rear end of the end detector connects the multi-core detection cable in the detector through the lead cable 16. 4 connected to the host 17.

Embodiment 3

[0059] Embodiment 3: During actual detection,

[0060] 1) Calculate the number of detectors required according to the depth of the borehole 14;

[0061] 2) Connect multiple detectors in order, and connect the sealing triangle cone 6 to the front end of the inlet, see image 3 ;

[0062] 3) Slowly send the connected detectors 15 into the borehole 14. Of course, each detector can be sent into the borehole 14 one by one according to the environmental conditions on site;

[0063] 4) Connect the connected detector 15 to the host 17 through the lead cable 16, see Figure 4 ;

[0064] 5) Repeat the above 4 steps, put the detector into another hole, and make sure the lead cable connects the detector to the host.

[0065] 6) Supply power to the two contact probes in one hole through the host, at this time, a current field is formed around the two contact probes, and then measure the distance between the two contact probes in the other hole Voltage value;

[0066] 7) The combinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com