Display substrate, manufacturing method thereof and display device

A technology of a display substrate and a manufacturing method, which is applied in the directions of semiconductor devices, electrical components, circuits, etc., can solve the problems such as the excessive size of the display panel frame.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] refer to Figure 1f with Figure 2d , this embodiment provides a display substrate, including a base 1 and a plurality of light emitting elements arranged on the base 1, each light emitting element participates in forming a pixel (for black and white display) or a sub-pixel (for color display) ).

[0029] The display substrate has a display surface and multiple side surfaces connected to the display surface. by Figure 1f Taking the current viewing angle as an example, the upper surface of the display substrate is the light emitting surface (for the case of top emission), and the left surface of the display substrate is a side surface.

[0030] The display substrate is divided into a central display area P2 and a plurality of edge display areas P1 located outside the central display area P2, and each edge display area P1 corresponds to a side surface. If the overall shape of the light emitting surface of the display substrate is rectangular, it has four sides, and e...

Embodiment 2

[0039] This embodiment provides a display device including the display substrate according to Embodiment 1.

[0040] Specifically, the display device can be any product or component with a display function such as an organic light emitting diode (OLED) display panel, a mobile phone, a tablet computer, a television set, a monitor, a notebook computer, a digital photo frame, a navigator, and the like.

[0041] The frame size of at least one side of the display device can be shortened.

Embodiment 3

[0043] see image 3 and combine Figure 1a-Figure 1f as well as Figure 2a-Figure 2d , this embodiment provides a method for manufacturing a display substrate. The display substrate of Example 1 can be manufactured by applying this manufacturing method. The display substrate has a display surface and multiple sides connected to the display surface. The display substrate is divided into a central display area P2 and a plurality of edge display areas P1 located outside the central display area P2. Each edge display area P1 corresponds to a side surface. The manufacturing method includes the following steps.

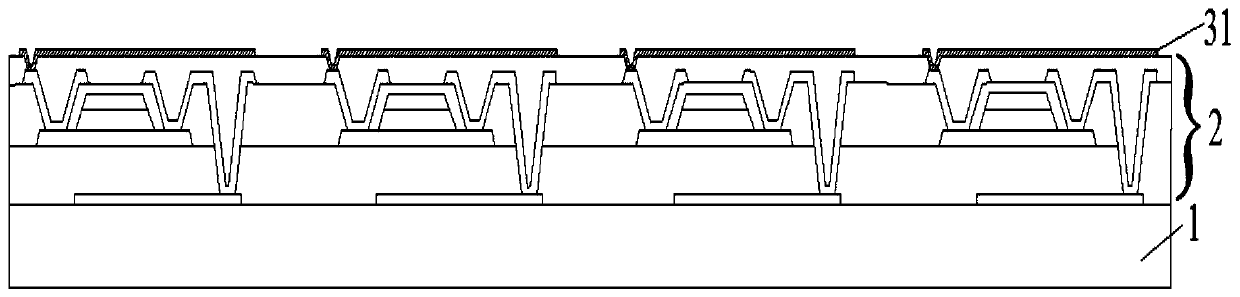

[0044] Step S1 , providing a substrate 1 on which a driving circuit layer 2 is formed, and a plurality of pixel electrodes 31 are exposed on the surface of the driving circuit layer 2 facing away from the substrate 1 .

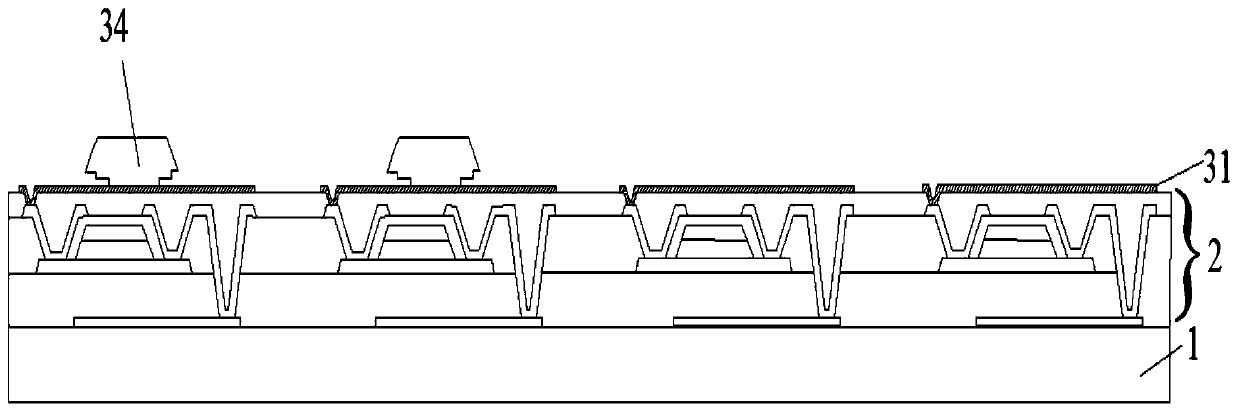

[0045]Step S2, transfer the micro light emitting diode 34 to the pixel electrode 31 in at least one edge display area P1.

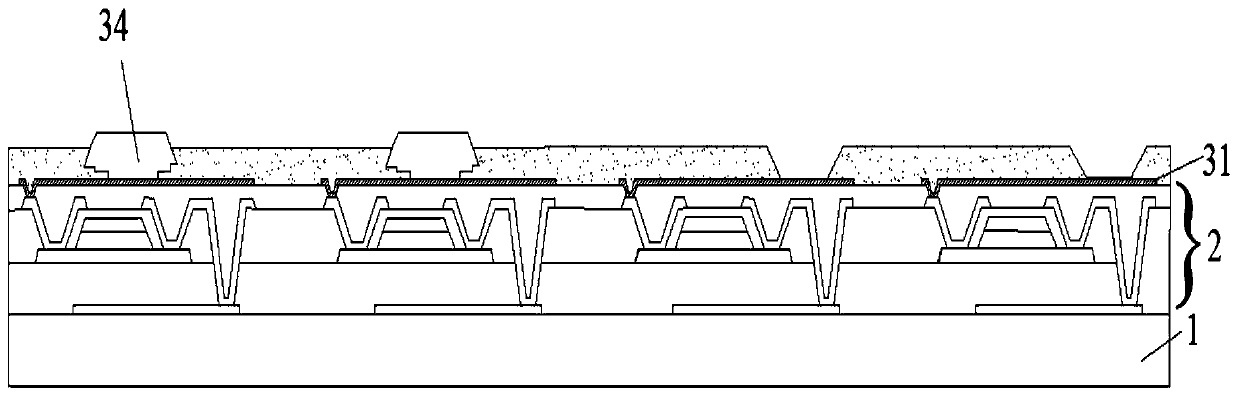

[0046] Step S3 , forming or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com