A kind of modular connector and mating method thereof

A connector and modular technology, which is applied in the direction of connection/disconnection, connection, and two-part connection device of the connection device, which can solve the problems of large insertion force and low contact reliability, and achieve the effect of compensating for positional errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

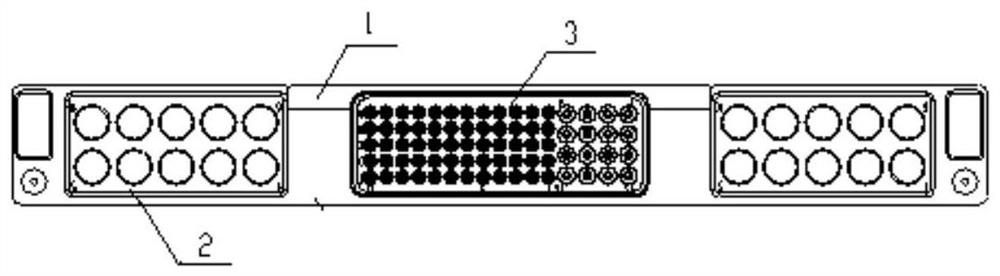

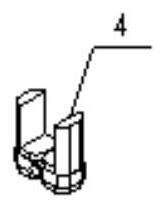

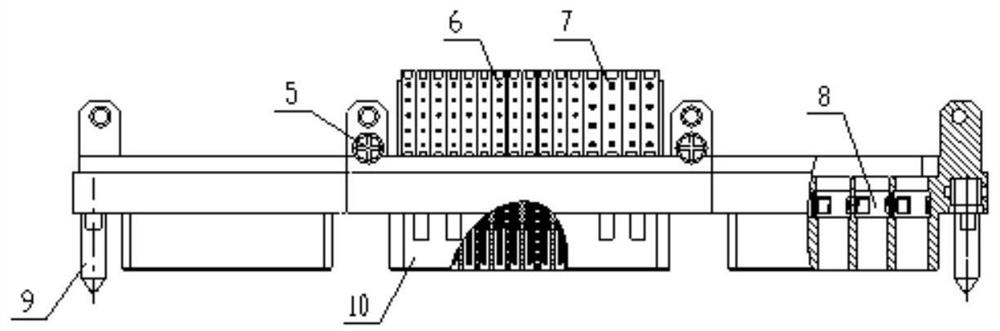

[0047] The present invention provides a modular connector such as Figure 1 to Figure 13 As shown, it includes a plug module and a socket module; the plug module includes a first brush needle assembly 6, a first power supply needle assembly 7, a first radio frequency assembly, a first mounting board 3, a first shield, a first plug shell 1 and a second Two plug shells 2; the brush pin assembly and the power pin assembly are fixed in the middle of the first plug shell 1 through the first mounting plate 3 and the first shield; the second plug shell 2 is arranged on both sides of the first plug shell 1 and used For fixing the first radio frequency assembly; the socket module includes the second brush needle assembly 14, the second power supply needle assembly 15, the second radio frequency assembly, the second mounting plate 17, the first socket housing 11; the second brush needle assembly 14 and the second The power pin assembly 15 is fixed on the first socket shell 11 through th...

Embodiment 2

[0066]This embodiment provides a guided mating method for a modular connector. Using the above-mentioned modular connector, the guided mating method includes the following steps:

[0067] Step 1. Align the plug module with the socket module, and insert the plug guide pin 9 into the socket guide pin jack for guidance;

[0068] Step 2. When the plug guide pin 9 is inserted into the socket guide pin socket to a depth of 3.8 mm to 3.9 mm, guide the second plug shell into the first socket shell;

[0069] Step 3. When the second plug housing guides into the first socket housing to a depth of 2.4 mm to 2.8 mm, the second brush needle assembly 14 starts to guide into the hole on the first mounting plate 3;

[0070] Step 4, the first pin contact is in contact with the second pin contact to generate a large number of contact points; the brush contact completes the blind insertion process. In step 4, when the first pin contact and the second pin contact are mated, the single-core contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com