Curtain coating nozzle for 3D printing equipment, and corresponding printing method

A 3D printing and spray coating technology, applied in metal processing equipment, 3D object support structures, coating devices, etc., can solve problems such as incomplete avoidance, limitation of printing efficiency improvement, and impact on the mechanical properties of printed objects. The effect of improving printing efficiency, improving efficiency, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

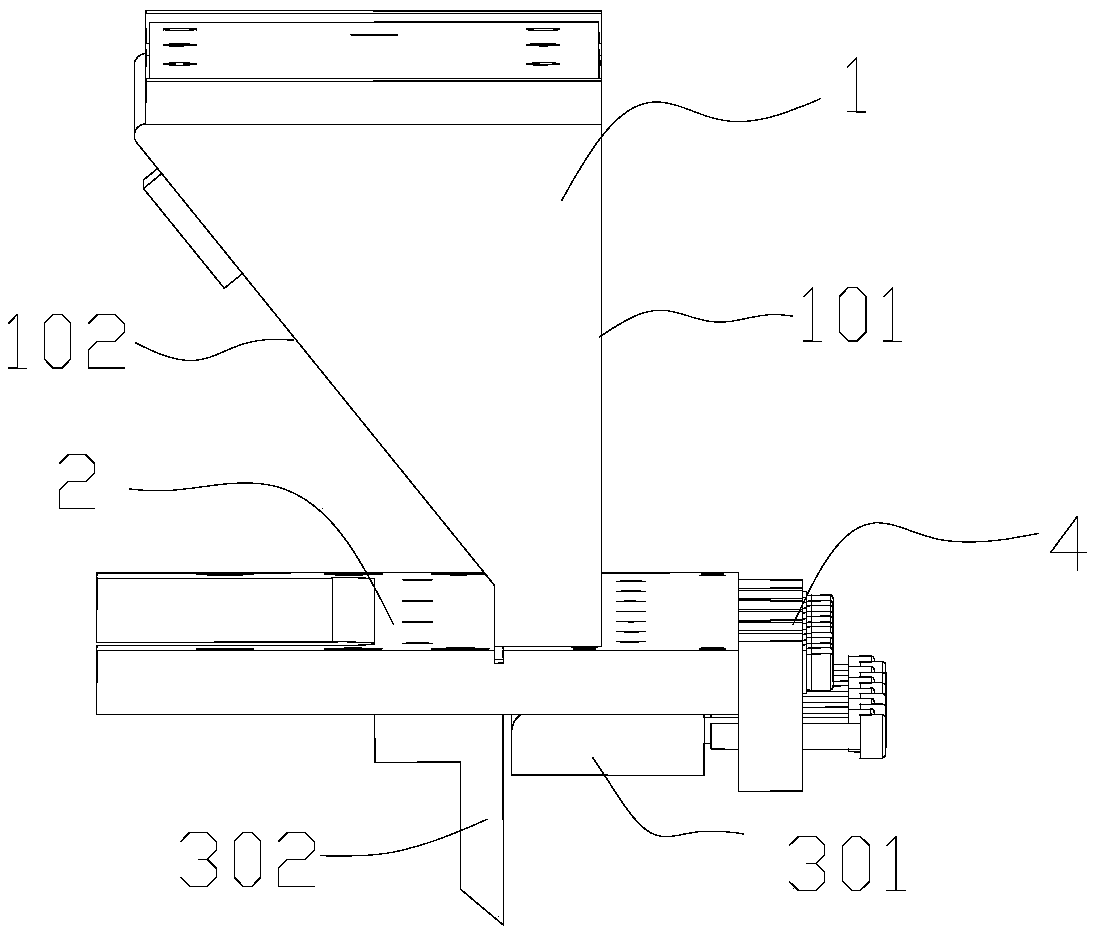

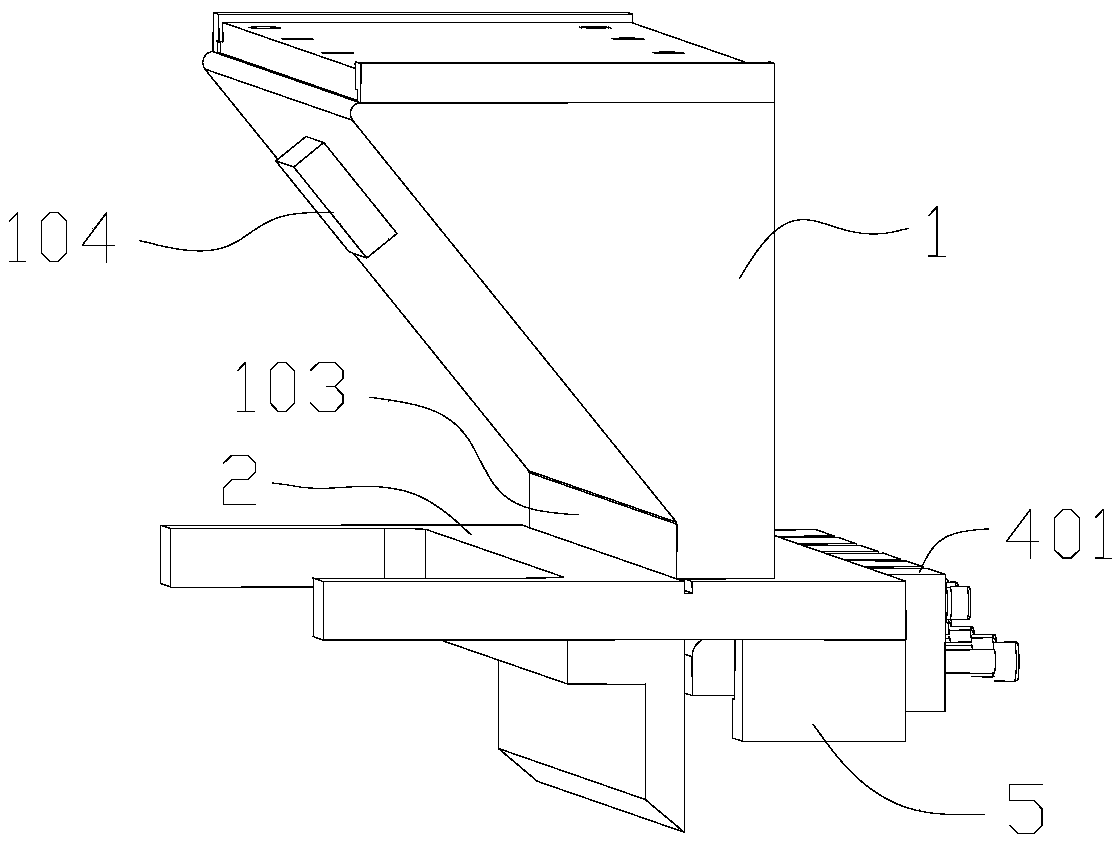

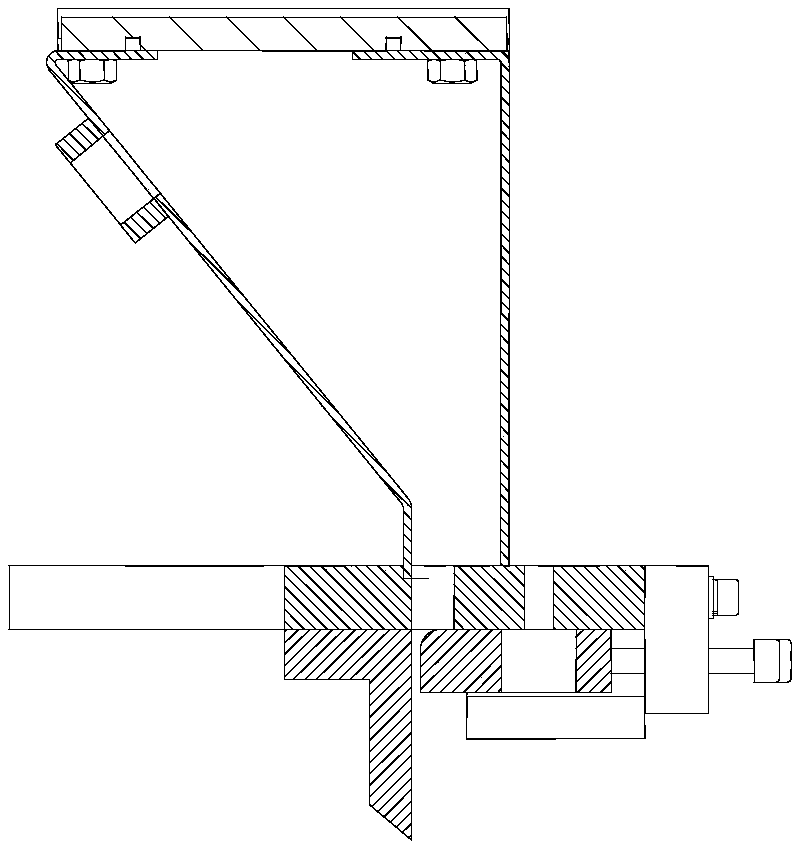

[0035] The present embodiment provides a kind of shower nozzle for 3D printing equipment, such as Figure 1-5 As shown, it includes: a shower chamber 1 for storing printing raw materials, a shower knife, a tensioning assembly 4, and an air knife 6.

[0036] The shower coating chamber 1 is a cavity structure, and its side is provided with a feed port 104 for introducing printing raw materials, and a slit for printing raw materials is formed at the bottom, around the slit, the bottom of the shower coating chamber 1 is fixedly equipped with The connecting plate 2 connected to the shower chamber 1; the shower chamber 1 is a plate-like structure with a slant plate 102 on the front side and a vertical plate 101 on the rear side. Through the design of the inclined plate 102 on one side and the vertical plate 101 on one side, the printing raw materials can be drained along the inclined plate 102 and poured out along the inclined plate 102, which can buffer the printing raw materials a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com