Multiscale ceramic reinforced aluminum matrix composite with dense arrangement body and preparation method thereof

A technology for reinforcing aluminum matrix and composite materials, which is applied in the field of multi-scale ceramic reinforced aluminum matrix composite materials containing close-packed bodies and its preparation, which can solve the problems of low ceramic volume fraction and poor elastic resistance, and achieve excellent elastic resistance, Delay the effects of premature failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

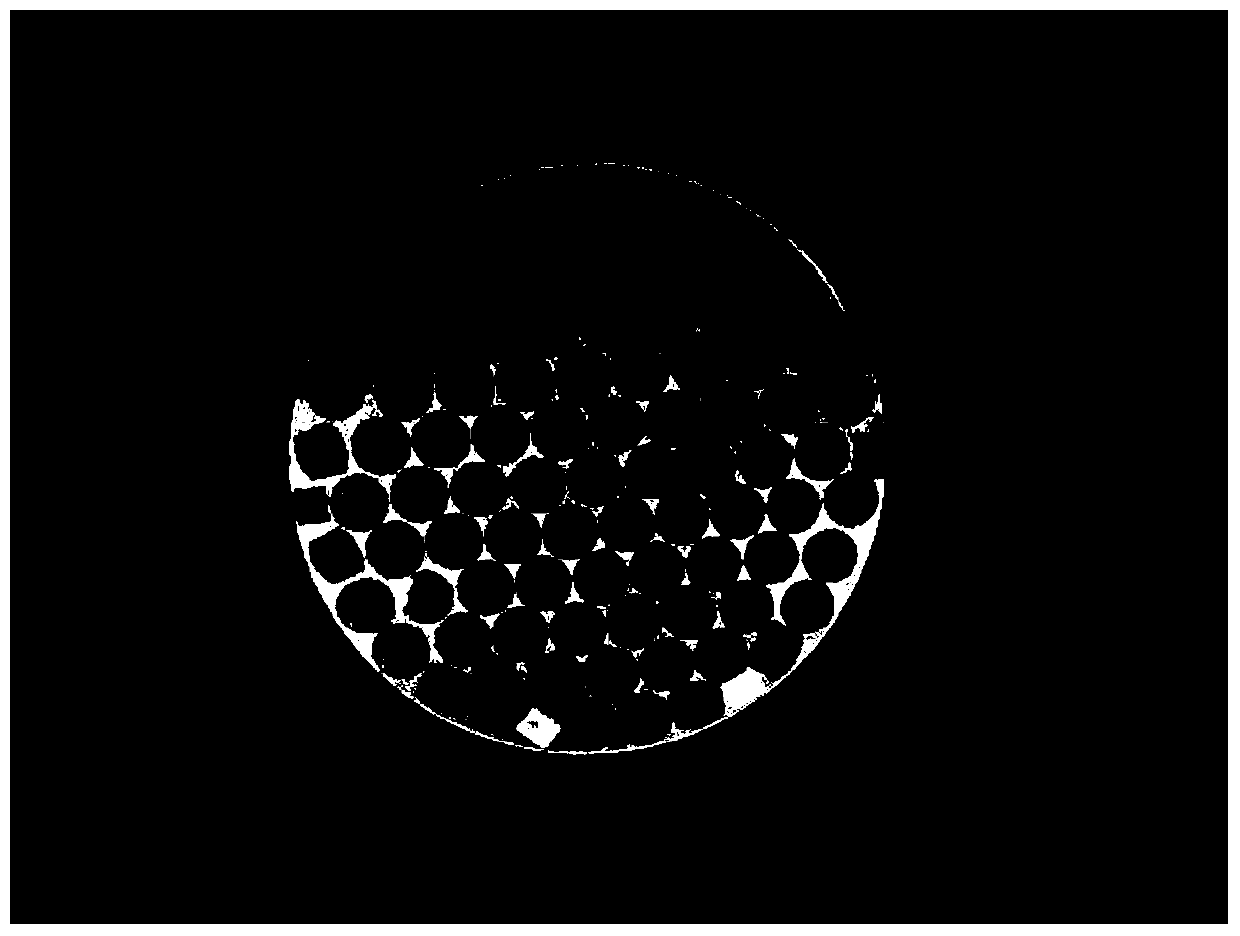

[0021] Specific embodiment one: this embodiment is a close-packed multi-scale ceramic reinforced aluminum matrix composite material composed of ceramic close-packed body, aluminum-containing material and ceramic powder filler; the ceramic close-packed body is composed of a number of ceramic columns The aluminum-containing material is aluminum or aluminum alloy; the packing density of the ceramic powder filler is 25-80%; the ceramic phase in the close-packed multi-scale ceramic reinforced aluminum matrix composite material The overall number of points is 65 to 93%.

specific Embodiment approach 2

[0022] Specific embodiment two: this embodiment is different from specific embodiment one in that: the ceramic cylinder is a cylinder with an arc on the end surface, the diameter is 2-30mm, and the aspect ratio is 0.3-5; the ceramic sphere The diameter of the sphere is 1-30mm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: This embodiment is different from specific embodiment one or two in that when the bulk density of the ceramic powder filler is 25-45%, the ceramic powder filler is composed of ceramic powder and Al Alloy powder is mixed; when the bulk density of the ceramic powder filler is 46 to 55%, the ceramic powder filler is a ceramic powder with a single particle size; when the bulk density of the ceramic powder filler When it is 56 to 80%, the ceramic powder filler is obtained by grading ceramic powder with different particle sizes; the ceramic cylinder is B 4 C ceramic cylinder or SiC ceramic cylinder, the ceramic powder is B 4 C powder or SiC powder, and the ceramic cylinder and ceramic powder are the same ceramic. Others are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com