A sample preparation method for tensile performance test of unidirectional carbon fiber cloth

A technology of unidirectional carbon fiber and tensile properties, which is applied in the field of material test sample preparation, can solve the problems of high test cost, uneven glue content of unidirectional carbon fiber cloth sample strips, and spline damage, so as to improve the tensile strength Accuracy and reliability, uniform distribution of epoxy resin, effect of eliminating stress concentration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A kind of sample preparation method of unidirectional carbon fiber cloth tensile performance test of the present invention, the steps are as follows:

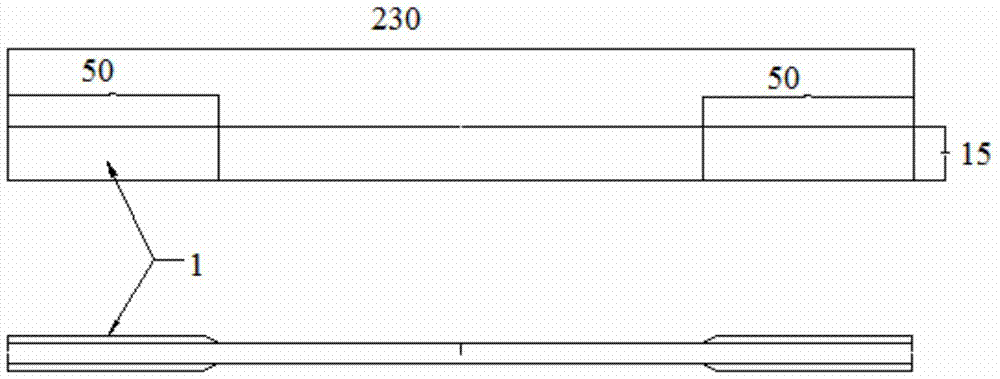

[0049] (1) Cutting sample: Cut out a carbon fiber cloth sample with a size of 250mm×250mm from the unidirectional carbon fiber cloth to be tested;

[0050] (2) Cleaning tools and moulds: clean the resin sheets, tools and moulds, and dry them with absolute ethanol (or acetone);

[0051] (3) Glue adjustment: Weigh the epoxy resin required for curing the unidirectional carbon fiber cloth matched with the unidirectional carbon fiber cloth in proportion, and mix evenly;

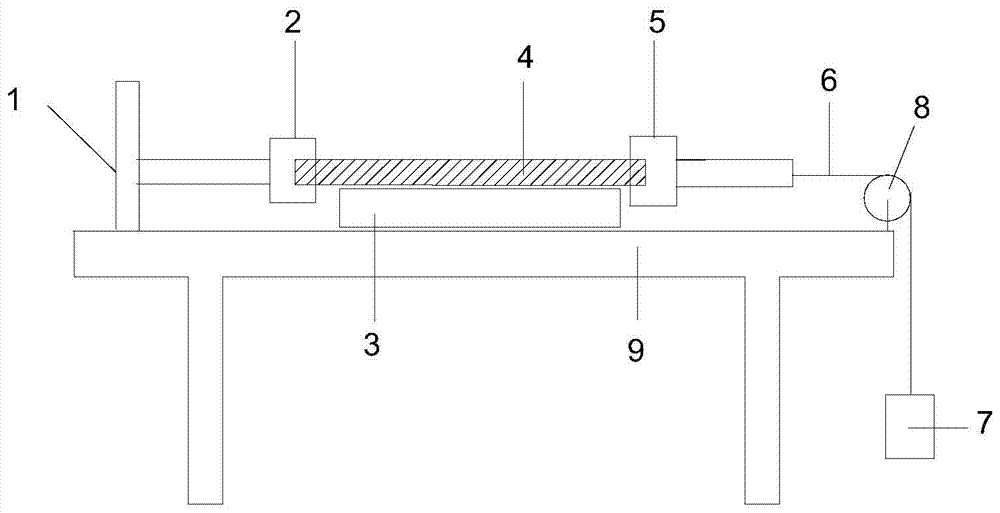

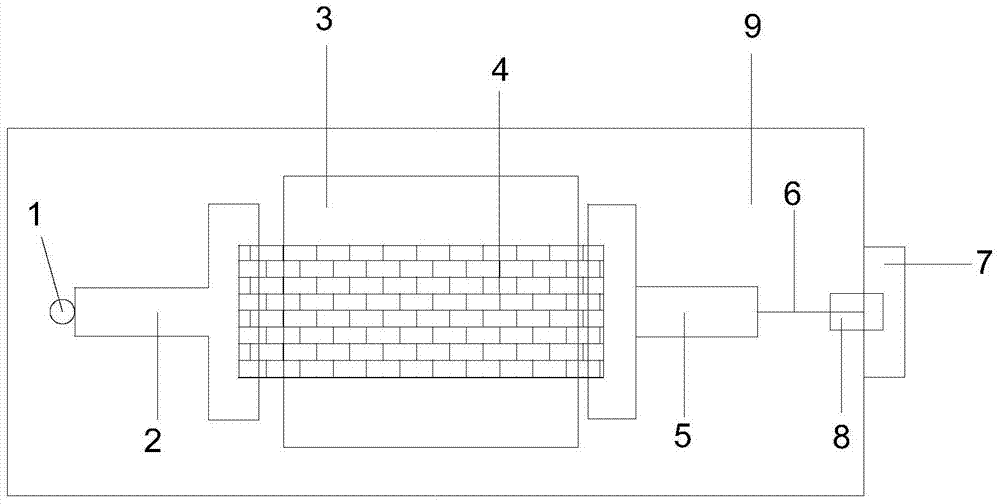

[0052] (4) Impregnated resin: such as figure 1 , figure 2 As shown, a resin sheet is placed on a glass plate or backing plate 3, and the well-mixed epoxy resin is divided into two parts A and B, wherein the mass ratio of the two parts A and B is 4:1; Pour it on the resin sheet, and scrape it with a scraper to make it evenly distributed. The size of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com