Applied-ignition internal combustion engine with two cylinder-specific valves and method for mixture formation in internal combustion engine of said type

An internal combustion engine and cylinder technology, which is applied to internal combustion piston engines, combustion engines, engine components, etc., can solve problems such as reducing the amount of tumbling in the combustion chamber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

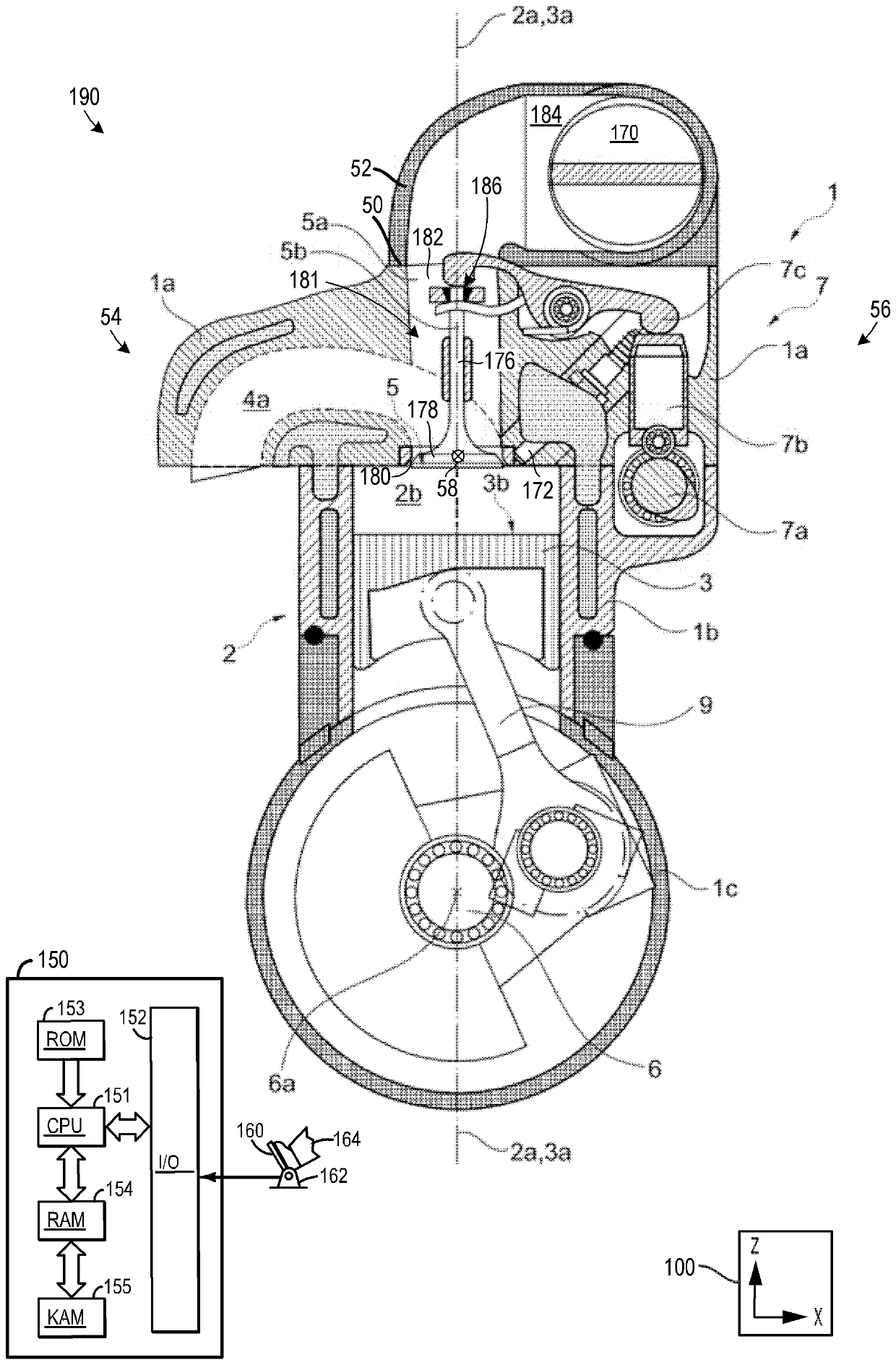

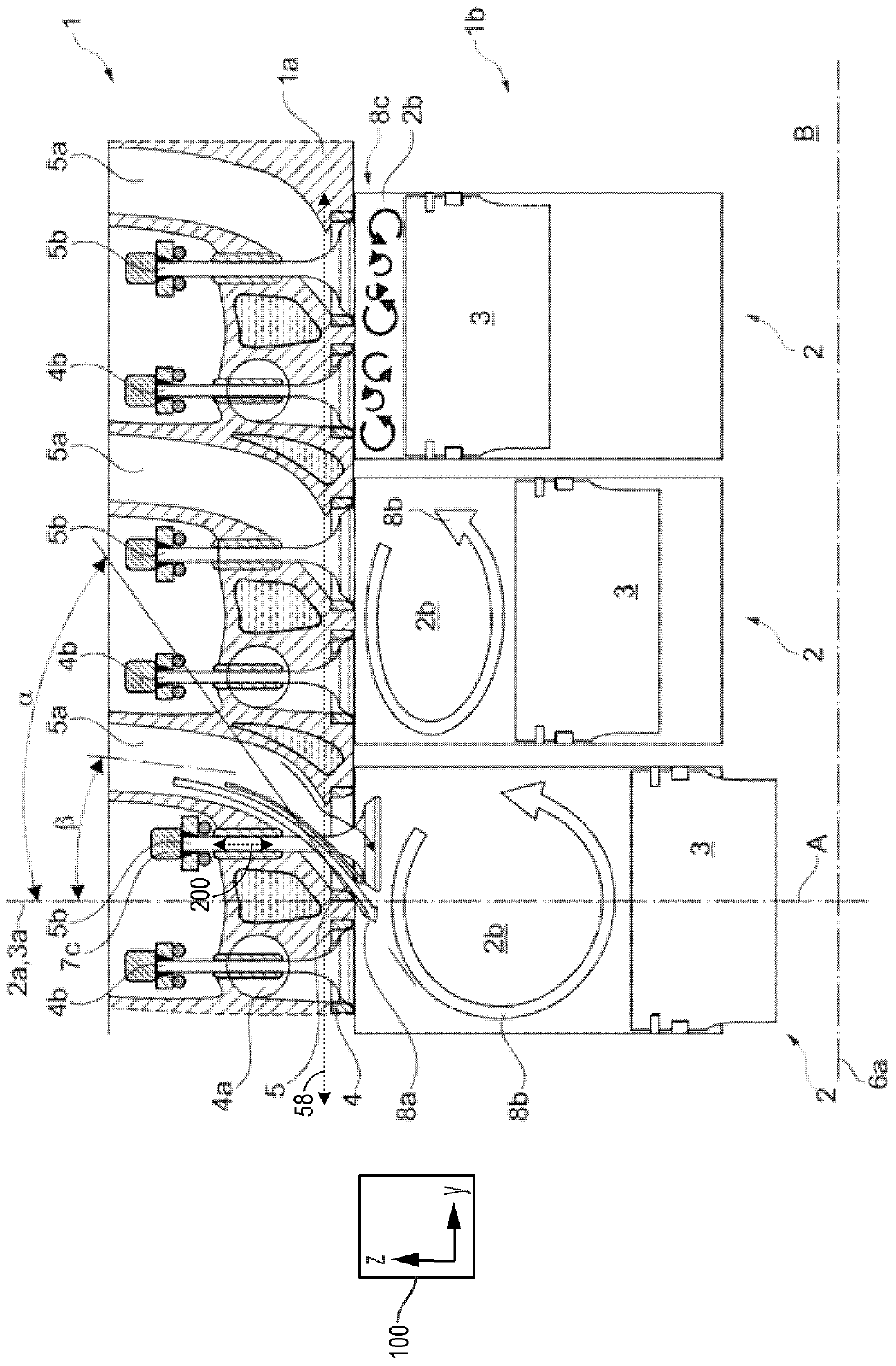

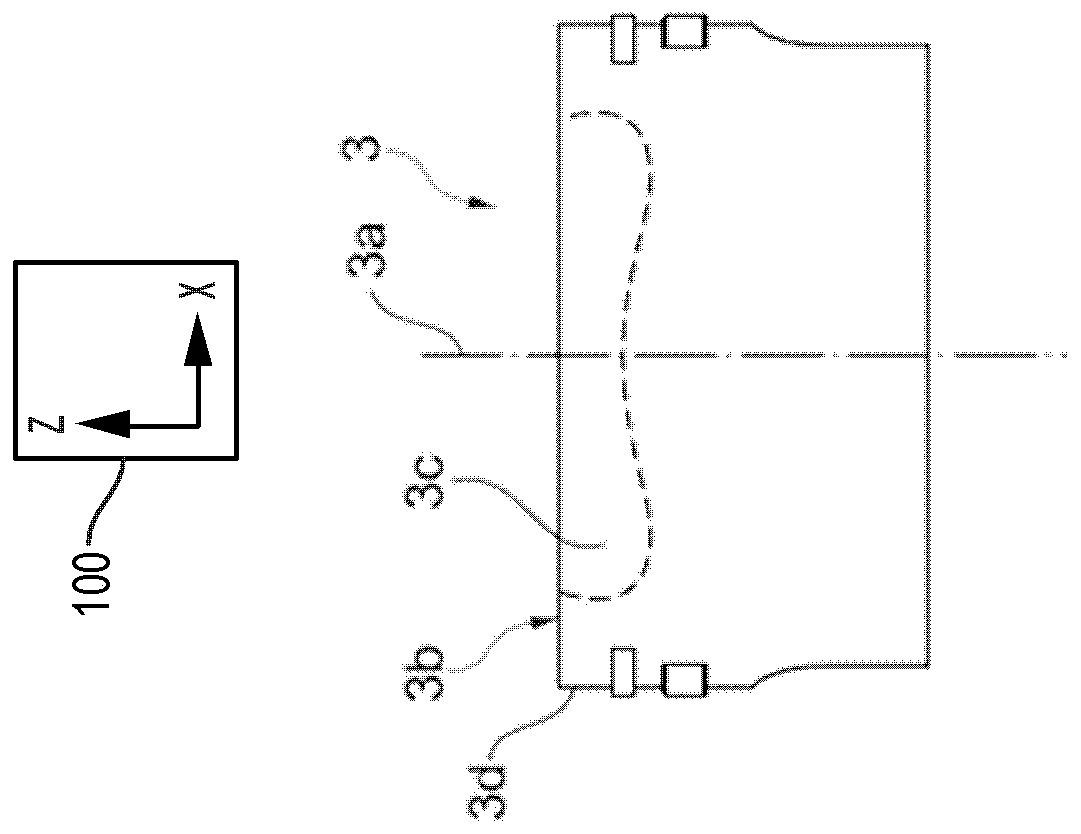

[0016] The present description relates to an applied ignition internal combustion engine having at least one cylinder head comprising at least one cylinder and having a rotatably mounted crankshaft. In this internal combustion engine, each cylinder has an intake port adjoining an intake line for supplying combustion air via an air intake system and an outlet port adjoining an intake line for releasing exhaust gases via an exhaust gas release system. Each air inlet is equipped with an inlet valve, and each air outlet is equipped with an outlet valve. Also, in this internal combustion engine, each cylinder includes a combustion chamber collectively formed by a piston crown of a cylinder-specific piston, a cylinder liner, and a cylinder head. Additionally, in this internal combustion engine, the crankshaft is articulately connected to the piston of each cylinder such that as the crankshaft rotates about the axis of rotation, the pistons oscillate along the cylinder longitudinal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com