Fuel distributor for internal combustion engines

A fuel distributor and fuel distribution technology, which are applied to fuel injection devices, special fuel injection devices, and adding non-fuel substances to fuel, can solve problems such as troublesome manufacturing of inserts, and achieve low-cost, simple manufacturing, and optimized geometry. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

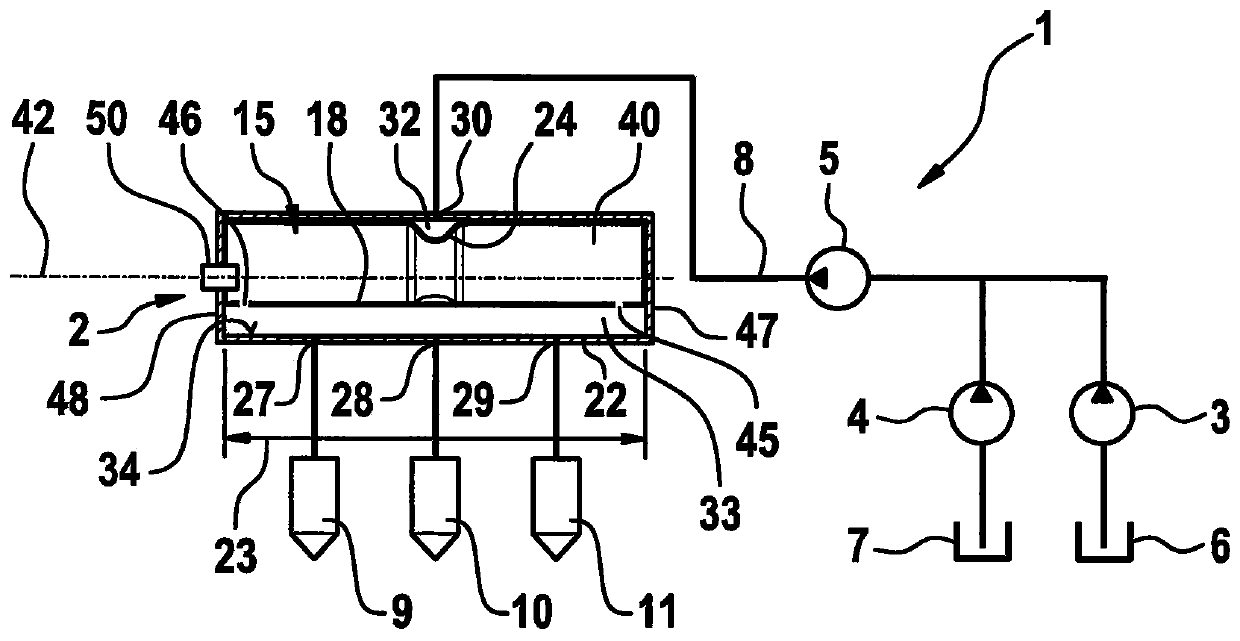

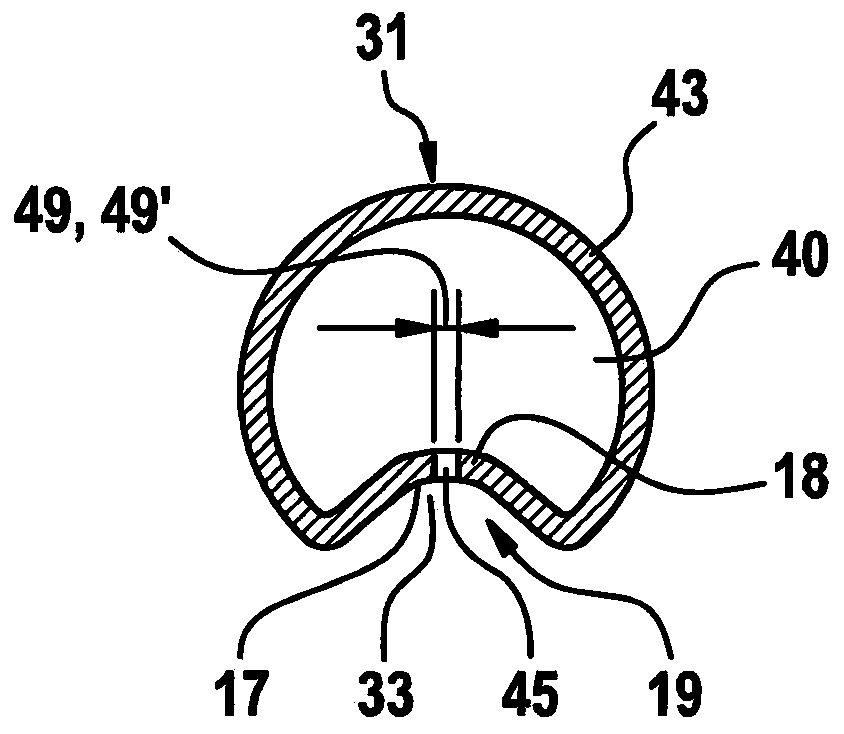

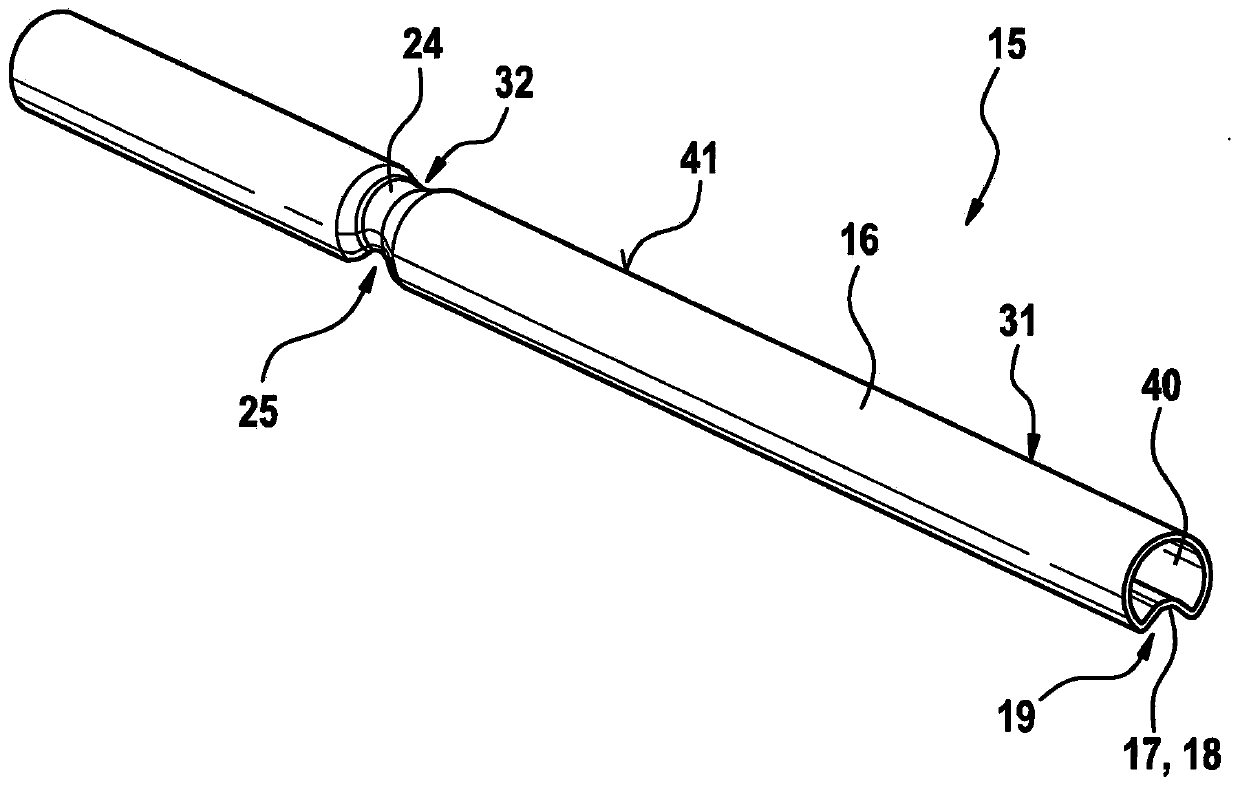

[0022] figure 1 A schematic illustration shows a fuel injection system 1 with a fuel distributor 2 according to a first exemplary embodiment of the invention, wherein the fuel distributor 2 is shown in a schematic sectional illustration. In this exemplary embodiment, fuel injection system 1 has a fuel pump 3 and a metering unit 4 designed as a backing pump 4 . Furthermore, a high-pressure pump 5 is provided. A fuel pump 3 delivers liquid fuel from a tank 6 to a high pressure pump 5 . The dosing unit 4 is used for temporarily dosing water from the storage container 7 into the delivered fuel. In this exemplary embodiment, the metering takes place upstream of the high-pressure pump 5 . In a variant, the metering can also take place at the high-pressure pump 5 . Depending on the operating state, liquid fuel or a mixture of liquid fuel and water is conveyed in line section 8 arranged between fuel distributor 2 and high-pressure pump 4 . Depending on the configuration, the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com