In-situ measurement planning method for high-steepness complex curved surface

A technology with complex curved surface and high steepness, applied in the field of curved surface measurement, can solve the problems of sparse measurement track and large longitudinal height difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific implementation manner of the present invention will be described in detail in conjunction with the technical scheme and the accompanying drawings.

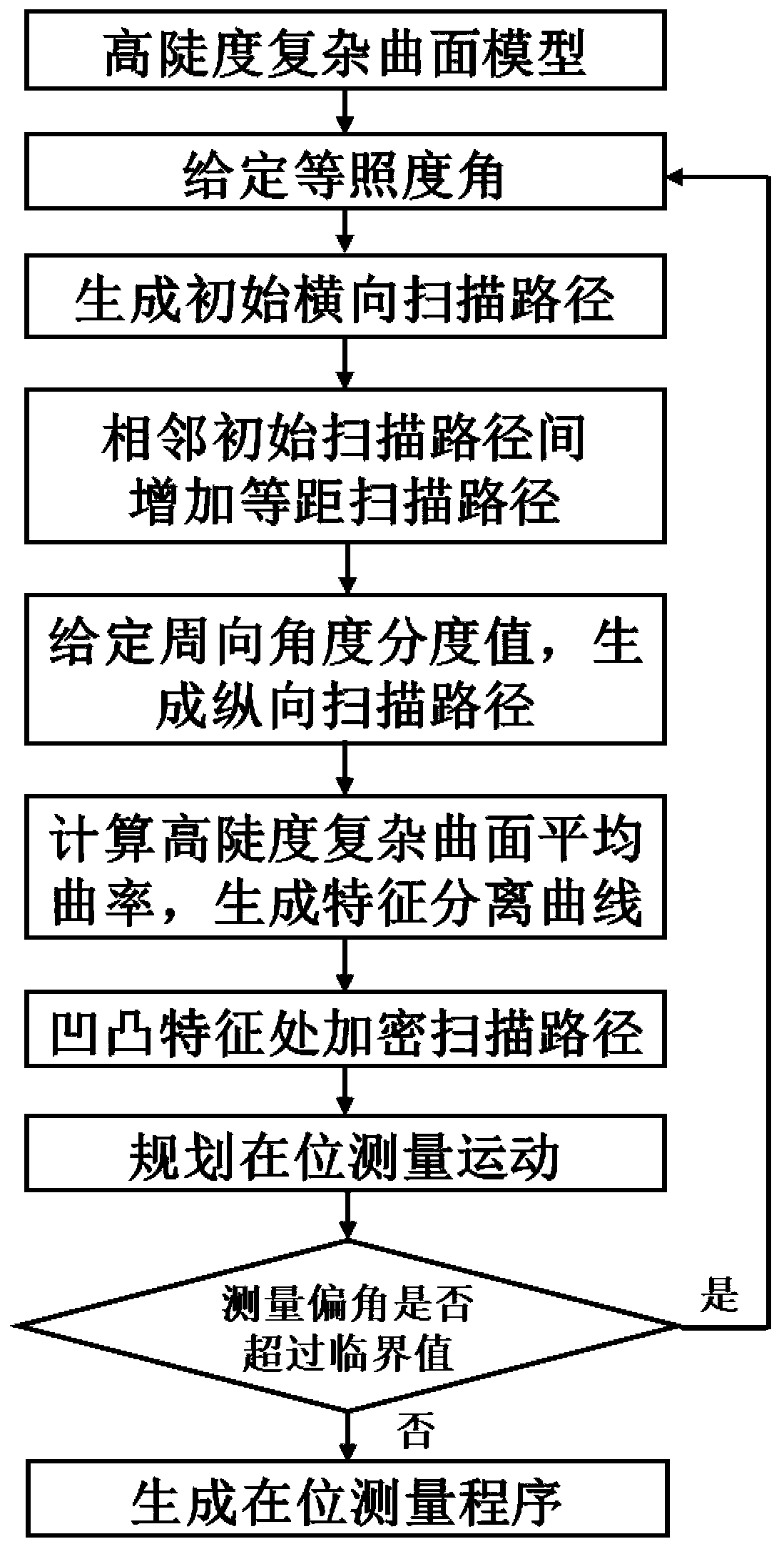

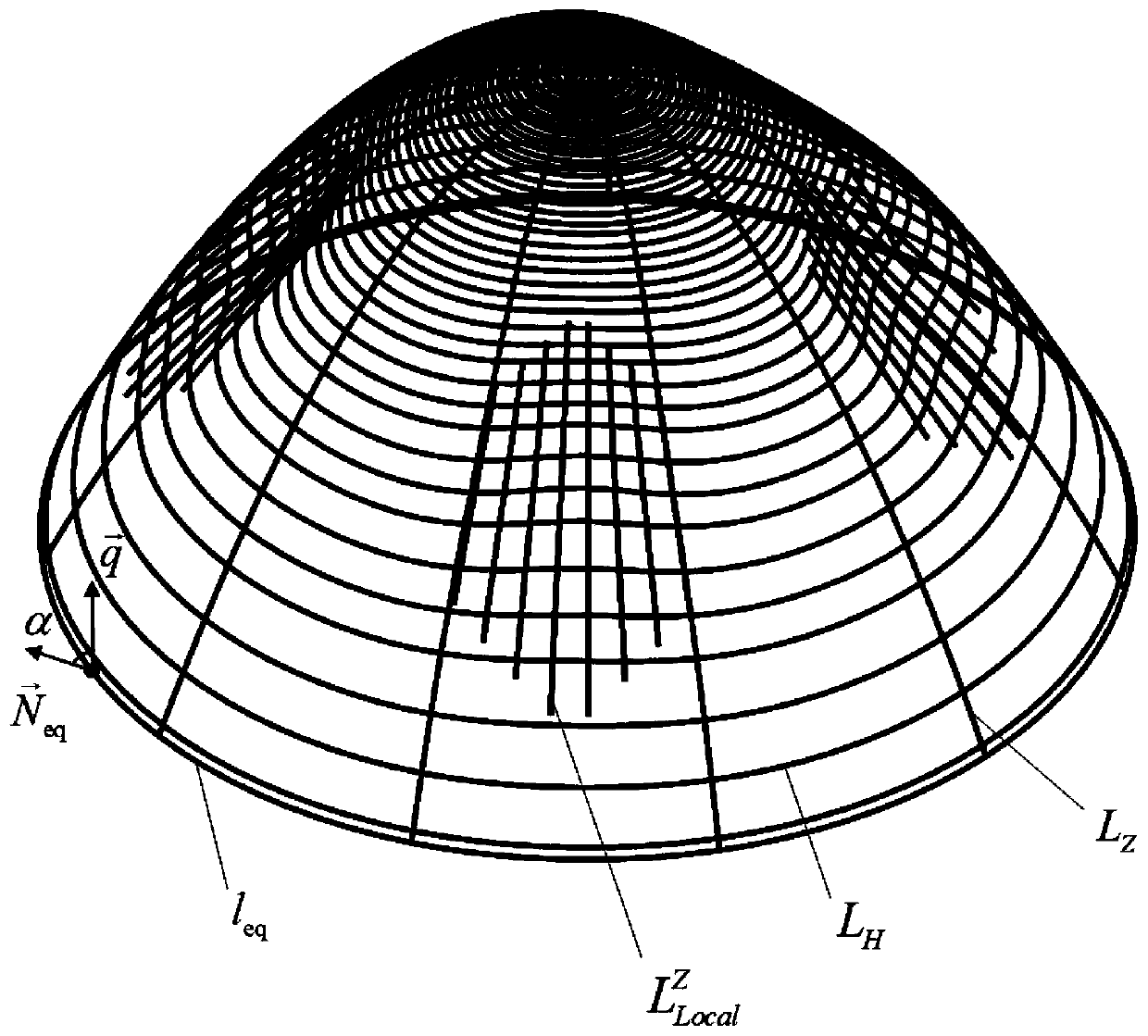

[0059] In this embodiment, the high-steep complex curved surface S used is a free-form surface with concave-convex undulations, a height of 52.5 mm, a diameter of 100 mm, and four non-rotationally symmetrical pits in the circumferential direction. attached figure 1 It is a flow chart of the planning method of the present invention, and the specific steps of the in-situ measurement planning of the curved surface are as follows:

[0060] Step 1 Generate an initial scan path

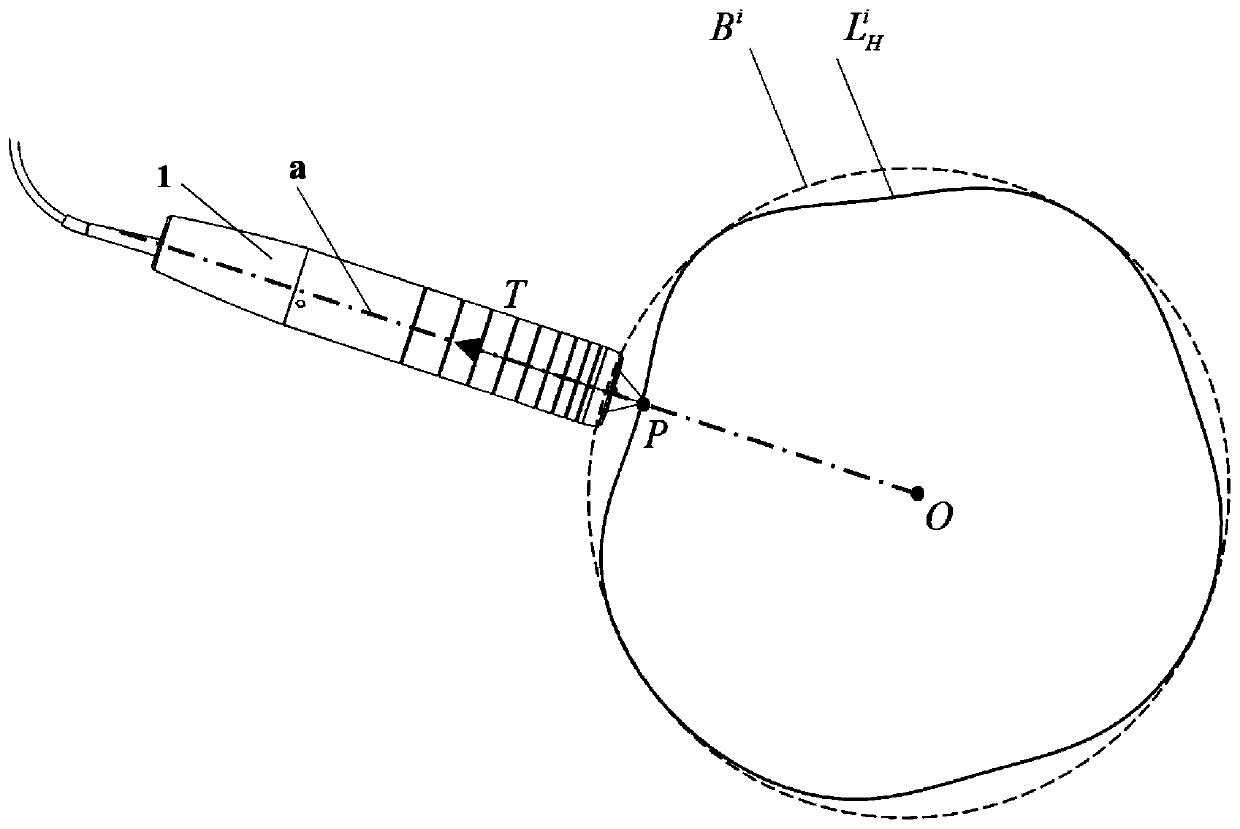

[0061] First, calculate the maximum steepness angle α of the containing aspheric surface A of the high-steep complex surface S, and the maximum steepness angle α is the edge section circle l of the mouth of the containing aspheric surface A eq The unit normal vector at any point on with the unit reference vector The included angle, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com