Capacitive coupling structure and dielectric filter applying same

A dielectric filter and capacitive coupling technology, applied in waveguide-type devices, circuits, electrical components, etc., can solve problems such as inconvenience in debugging, and achieve the effect of large adjustable range of coupling coefficient, wide technical application range, and convenient later debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with the accompanying drawings, to better understand the technical solutions and related mechanisms of the present invention:

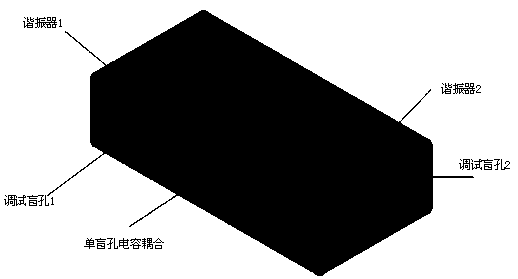

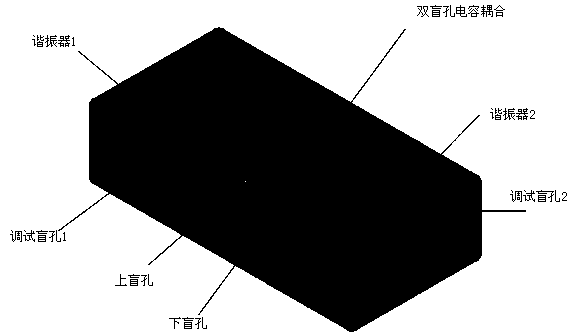

[0027] The present invention proposes a capacitive coupling structure with double blind holes, such as image 3 and Figure 4 Shown (the first implementation of capacitive coupling). Each dielectric resonator includes a body made of solid dielectric material and a debugging hole located on the surface of the body. The debugging hole is a blind hole for debugging the resonant frequency of the dielectric resonator where it is located. At least a pair of opposite negative coupling holes in the form of a blind hole structure are introduced between the two surface-metallized dielectric resonators 1 and 2, ie upper blind holes and lower blind holes (referred to as double blind holes). The upper blind hole is located on the surface where the two debugging blind holes 1 and 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com