Low-viscosity energy-saving engine oil composition with low-speed preignition control performance

A technology for engine oil and performance control, applied in the field of lubricating oil, can solve the problems that the anti-friction performance cannot be guaranteed, and the pure calcium salt system is difficult to achieve, etc., and achieve good anti-wear effect, strong operability and obvious technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

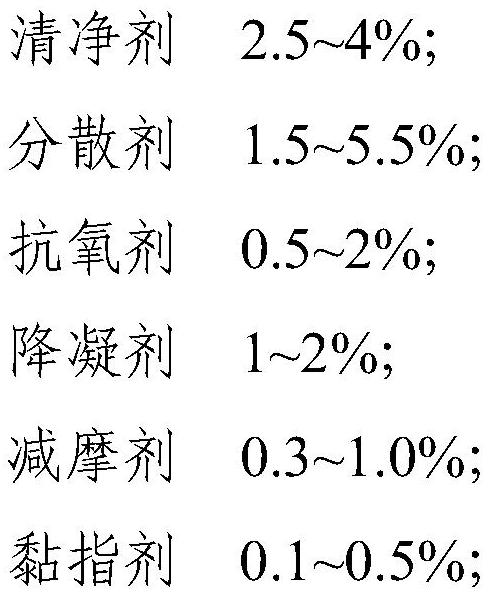

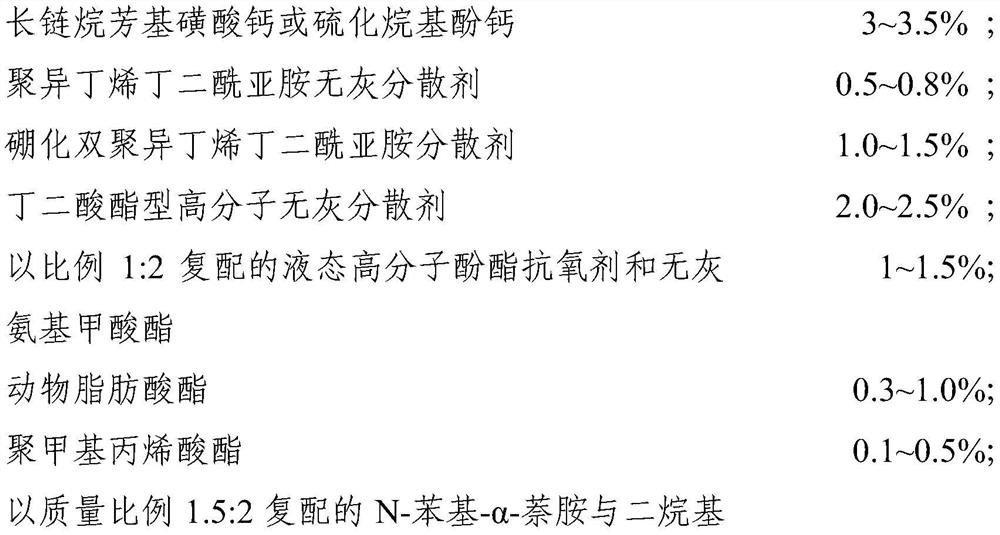

Method used

Image

Examples

Embodiment

[0035] The composition preparation scheme is shown in Table 1.

[0036]

[0037] Table 2 Lubricating oil composition example energy saving test (WLTC cycle) comparison

[0038]

[0039] As can be seen from Table 2, the energy-saving performance embodiment 1 (0W-16) is significantly better than the comparative example 1 (0W-16). In embodiment 1, the energy-saving performance has been improved due to the addition of the organic friction reducer and is better than adding molybdenum-containing Energy-saving effect of friction reducer.

[0040] Table 3 Lubricating Oil Composition Example High Temperature Metal Corrosion Test (HTCBT) Comparison

[0041] Copper corrosion increase / ppm Example 1 (0W-16) 7 Example 2 (0W-20) 8 Comparative example 1 (0W-16) 39 Comparative example 2 (0W-20) 7.7

[0042] It can be seen from Table 3 that, since no organic friction reducer was used in Comparative Example 1 (0W-16), a molybdenum-containing salt fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com