Industrial control protocol fuzzy test method based on flow replay

An industrial control protocol and fuzzy testing technology, applied in the direction of digital transmission systems, electrical components, transmission systems, etc., can solve problems such as difficulty in establishing a conversation process, low test coverage, incorrect information, etc., and achieve the effect of shortening the test preparation stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

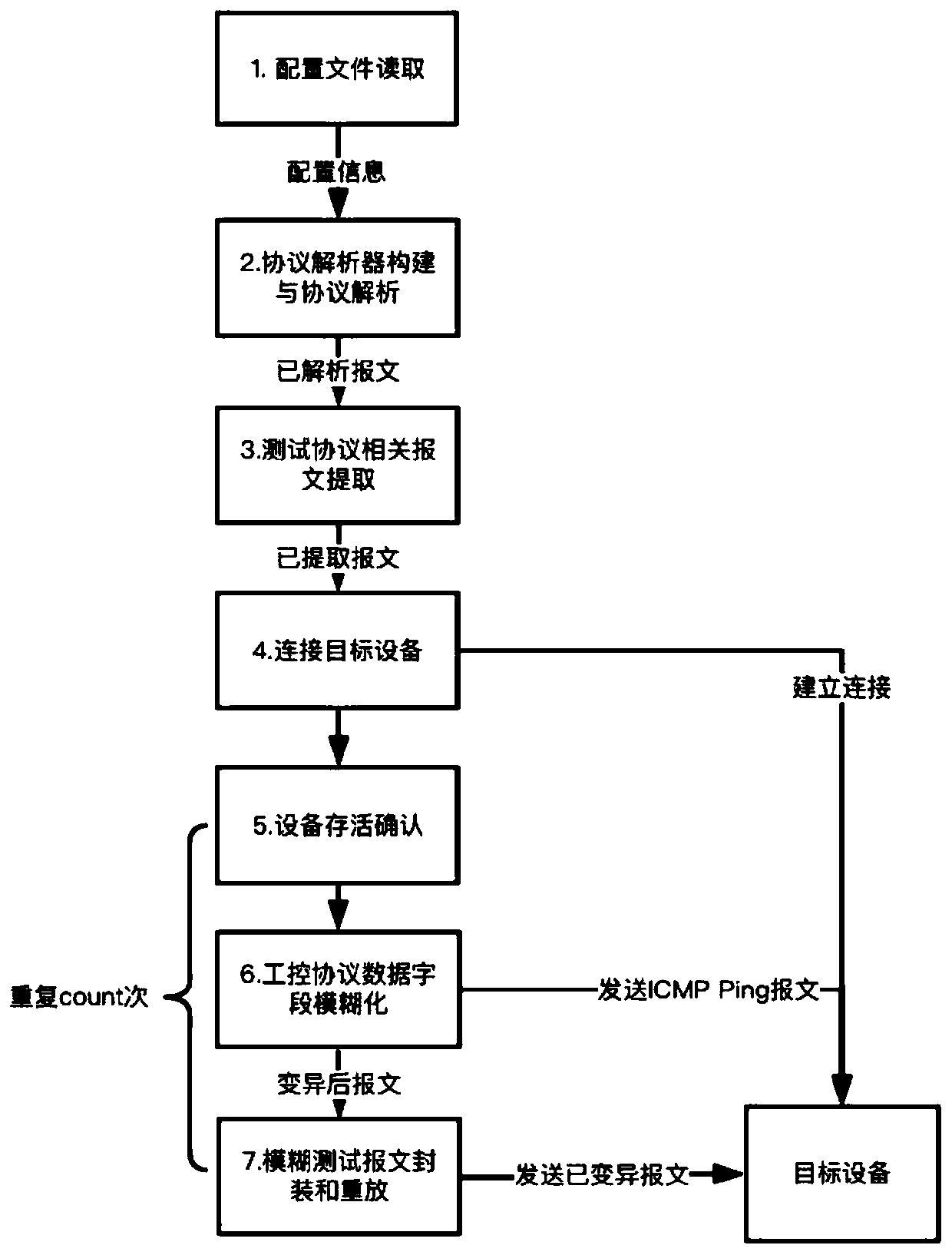

[0030] In order to better explain the solutions of the present invention, the implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

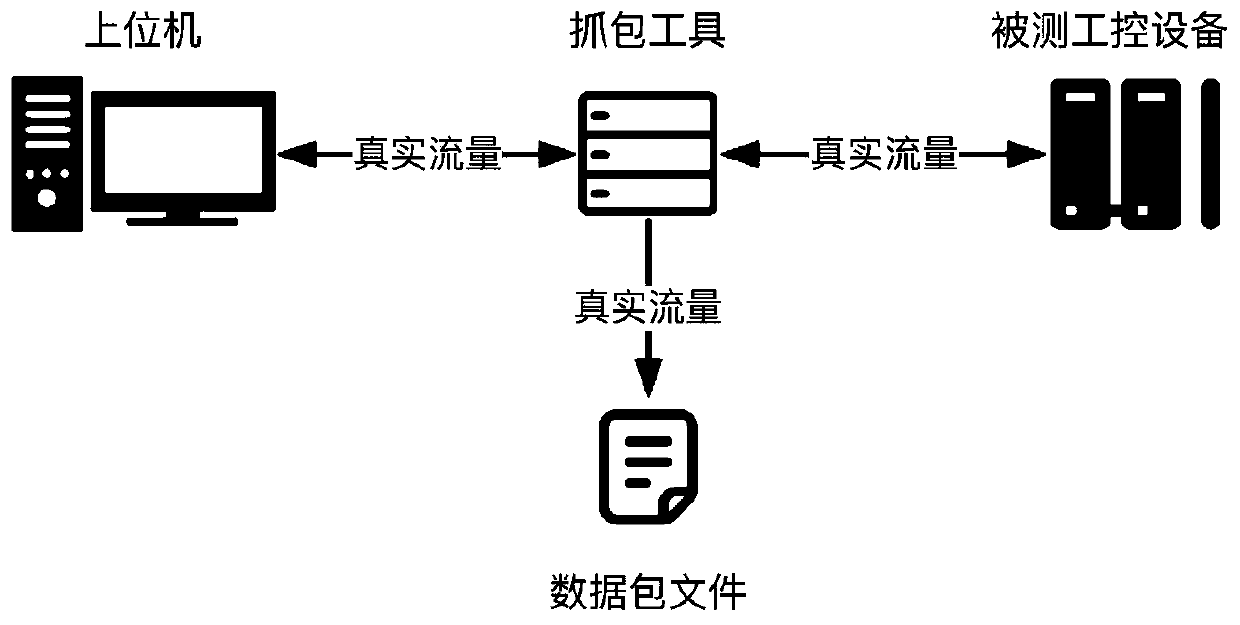

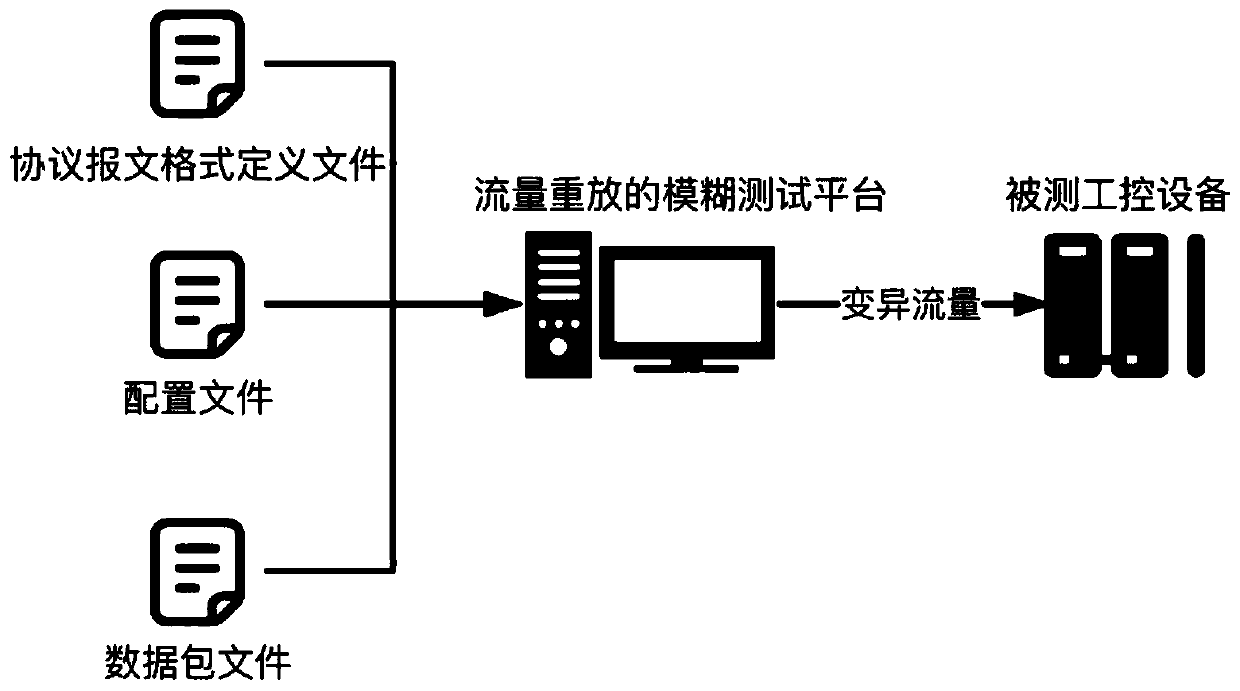

[0031] The invention provides an embodiment of an industrial control protocol fuzzy testing method based on traffic replay. Real industrial control protocol packets need to be obtained before testing, such as figure 1 As shown, the packet capture tool is placed between the host computer and the industrial control device under test. The packet capture device can be a switch with port mirroring enabled or a packet capture tool such as Wireshark opened on the host computer, and finally the datagram file is obtained. later as figure 2 As shown in , the datagram file, configuration file, and protocol message format definition file are used as the input of the whole method, and after being processed by the fuzzy testing method, the mutated message is sent to the target device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com